Motor rotor in the production process, there is an important process, is the insertion of magnetic sheet or paste magnetic sheet, the traditional are basically by manual insertion of magnetic, magnetic sheet less okay, if a rotor needs to insert multiple magnets, it is more trouble, not only inefficient, and labor costs increase.

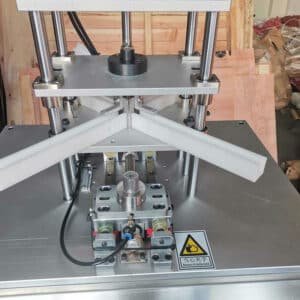

Magnetic Steel insertion

Nowadays, in order to realize the automatic production of rotors in large quantities, automatic magnet insertion machine starts to replace manual labor, whether it is a single machine or inline automatic production, the efficiency has been upgraded to a great level.

Automatic magnet insertion machine, there is a magnet rotation lifting device, adjust the height, the top is the magnet work surface, after the material on, the empty rotor put on the mold, or through the flow line to the corresponding position, through the cylinder top up or down insert, automatic magnet insertion, inserted, flow to the next step, this is a fast, accurate, high efficiency, high yield automatic magnet insertion method, is the motor manufacturers Indispensable motor production equipment.

Automatic magnet insertion machine features.

1. Can insert multiple magnets at the same time, fast and convenient, 1-2 seconds to complete the magnet insertion process.

2. Height can be adjusted, can adapt to different heights of products.

3. Rodless cylinder, guide rail and linear bearing are used, which is practical and durable.

4. The overall frame is made of aluminum alloy and sheet metal, beautiful and atmospheric.

5. Once you see it, just put the empty rotor on top of the mold and press the start button.

6. Easy to change the type, only need to adjust the height and position.

Automatic Magnetic Steel Insertion Machine

The above is the working principle and functional characteristics of the automatic magnet insertion machine, with this equipment, the insertion of magnets becomes easy to work, the motor rotor production more efficient!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com