First, ordinary CNC winding machine

Ordinary CNC winding machine is our common winding equipment. This series of products cover a wide range, including small and medium-sized models and large models. The control system generally adopts single-chip computer circuit. Because of its low price, stable performance, easy maintenance and other characteristics, has been widely used by transformer manufacturers.

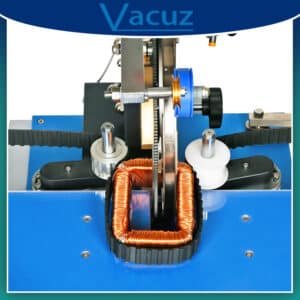

Second, automatic winding machine

The emergence of automatic winding machine, greatly reducing the operator’s winding intensity. Our common automatic wire winding machines generally use cnc controller, high-end models use plc and precision servo system to meet the needs of modern electrical appliances. The speed of the wire machine is getting higher and higher, and the processing capacity is also increasing. The wire tensioning mechanism is used in conjunction to make the wound coil beautiful and neat.

III. Foil Winding Machine

Foil winding machine is mainly used to wind foil coils. Its structure and function are much more complicated than the ordinary winding machine. Tension control and foil tape guiding are the key technologies of foil winding machine. There is still a gap between imported equipment and domestic manufacturers. Domestic manufacturers have invested and paid more attention to this aspect, and the technical problems are gradually solved.

Fourth, vertical winding machine may not be common with vertical winding machine. It belongs to special equipment. Vertical winding machine is generally used for large transformers in high-voltage coil winding, low-voltage spiral coil is also used vertical winding machine. Type winding machine, its working principle and processing range and our common parallel winding machine is completely different.

Five, three-dimensional winding core winding machine

Three-dimensional iron core three-dimensional winding machine with a high degree of automation. It only needs to input the number of gear teeth of the winding coil on the operation screen, and then the number of winding turns can be directly displayed, avoiding the error of manual calculation and the traditional error of the number of winding turns. The device realizes the working mode of winding personnel sitting and winding, which greatly reduces the labor intensity. At the same time, the three-dimensional winding machine has reversible and power failure memory function, simple and reliable operation, high efficiency, wide range of applications and other characteristics. It is a new generation of intelligent three-dimensional core winding coil winding equipment.

Six, the main features

1. Computer (MCU) control, full key operation panel structure, digital display of the working status.

2. With preset number, manual or pedal start, acceleration, deceleration and power failure memory function.

3. Intelligent “abnormal early warning” function, when there is “probe signal abnormality”, “misrecording, over-recording”, “over-value When there is “abnormal probe signal”, “mis-recording, over-recording”, “over-value”, it can carry out early warning and stop the machine.

4. The full-rotation automatic stop adopts program control to decelerate in advance, which can eliminate the influence of rotational inertia and make the counting accurate and reliable.

5. “Electric killing car” can work in the emergency stop state.

6. In the “big transformer state”, the controller does not make “abnormal judgment”, will not abnormally shut down, you can wind the wire at will.

7. “Rewind” function can realize the electric back avoidance.

8. The foot pedal control has the function of positive and negative starting and stopping.

9. The counting probe can accurately and reliably detect the number of laps away from the end face of the coil frame, solving the problem of unreliable counting caused by the probe hitting the roller and the skeleton movement.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]