In the winding operation of the automatic winding machine, the winding system of the line components, directly affects the processing efficiency of the winding equipment and the accuracy of the coil line, when there is a failure, the user is usually difficult to solve the problem, common failure analysis how the following.

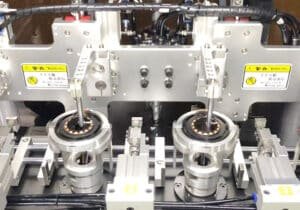

Прецизно навиване на безчетковия двигател

1. Failure caused by the drive motor

The drive motor is usually a stepper motor or servo motor, and the automatic winding machine wiring components are usually controlled by a special driver. When a failure occurs, the wiring system will move irregularly and cannot be wired correctly and properly. This type of failure is usually caused by irregularities in the wiring of the equipment.

2. Failure caused by synchronous rotating parts

Synchronous rotating parts are wearable parts of the winding machine equipment and can cause certain problems after a long period of operation, which can affect the accuracy of the equipment wiring. For example, the belt tightness can be adjusted. When the equipment is used for a period of time, it should be adjusted in time to keep it within the specified value.

3. External interference and load-induced failure

The so-called external disturbance usually refers to the movement caused by the unstable operation of the moving parts. The greatest resistance to the wiring system of the winding machine is commonly caused by the lack of regular lubrication in the system, as well as the over-range processing and winding performed by the user when using the equipment, and these external forces can affect the accuracy and normal operation of the wiring.

BLDC машина за навиване на бобина

The above is a common fault analysis of the winding machine line components, only to master these causes and solutions to make the winding machine run more stable and smooth.

WhatsApp/Wechat: +86 13075286997

Имейл: sales@vacuz.com