Brushless stator winding mainly has internal winding and external winding methods, common internal winding using needle winding method, then how to ensure that the internal winding machine winding accurate and fast? What is the method? The following Vacuz to analyze it!

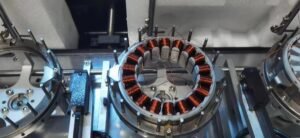

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

To ensure that the internal winding machine winding accurate and fast, the following methods and strategies can be used:

1. Optimize the winding method: design a simple and efficient winding method to reduce unnecessary winding time and complexity, and improve the winding efficiency.

2. Adopt advanced control system: Adopt bus type PLC motion controller with professional servo system to ensure that the winding accuracy meets the requirements. Through programming control, the trajectory, angle and speed of the winding tool can be accurately set to meet specific winding requirements.

3. Tension control: High-quality tension sensor and tension control system can monitor and control the tension of the enameled wire material in real time, so as to keep the tension within the proper range and ensure the stability and quality of the winding.

4. Automatic operation: realize automatic operation, touch screen programming, free to add action instructions, debugging and maintenance is convenient. Realize the function of automatic corner wrapping, reduce manual operation and improve production efficiency.

5. Quick reset function: after winding is completed, use the reset command to quickly reset the equipment, reduce waiting time and improve the efficiency of winding.

6. Adjust the speed according to the wire and process, the speed should not be too fast, nor too slow.

7. Servo motor and configuration selection: Selection of high-quality motor and configuration, such as Panasonic, Fuji and other foreign imported brands, to improve the efficiency and stability of the winding with high configuration.

8. System monitoring and safety: monitor and protect the operation status and safety of the system, including monitoring and alarming of parameters such as temperature, current, force, etc., as well as protecting and detecting faults of key components such as motors and transmissions.

9. Customized solutions: according to the specific product, wire, process and output requirements, customize the configuration and parameters of the internal winding machine, to meet the winding accuracy at the same time, to ensure that the winding speed meets the requirements.

10. Training and operation standardization: professional training for operators to ensure that they are familiar with the operation and maintenance of the internal winding machine and follow the operation standardization to reduce the impact of human error on the winding accuracy and speed.

High Precision Vacuz Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine + Rotor Magnet Steel Insertion Assembly Machine

How to ensure the accuracy and speed of internal winding machine? Vacuz above has made a brief introduction, I hope these tips can help you!

Имейл: sales@vacuz.com