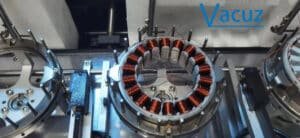

Brushless motor stator winding, generally using specialized automatic winding machine equipment, common flying fork external winding machine and needle internal winding machine equipment, the two winding methods are different, but due to the existence of machine and human reasons, sometimes the phenomenon of injury line, resulting in product quality is not acceptable, so what are the reasons for the injury line of the brushless motor stator automatic winding machine? How to avoid wire wounding, Vacuz give you an analysis! I hope it can help you!

Vacuz 4&6 Stations Electric Toothbrush Motor Automatic BLDC Brushless Inner Hair Dryer Stator Coil Needle Winding Machine Equipment Price

Brushless motor stator automatic winding machine wire injury causes, there may be the following points:

1. Winding speed is too fast: when the winding speed exceeds the specified speed, it is easy to subject the wire to excessive tension, which may lead to wire breakage or damage.

2. Inappropriate wire or wire diameter: If the wire material used or wire diameter does not meet the requirements of the equipment, such as wire diameter is too thin or too thick, it may cause improper tension on the wire when winding, which may lead to damage to the wire.

3. There are foreign objects on the nozzle or burrs on the frame: these foreign objects or burrs may scratch the wire during the winding process, causing damage to the wire.

4. The tensioner is not properly adjusted for tension: too much or too little tension may cause damage to the line. Too much tension may easily break the wire, while too little tension may make the wire loose during the winding process, affecting product quality.

In order to avoid damage to the wire by the automatic brushless motor stator winding machine, the following measures can be taken:

1. Strictly follow the winding speed specified in the equipment manual or the winding speed recommended by the manufacturer, and avoid too fast or too slow winding speed.

2. Use wire and wire diameter that meets the requirements of the equipment and make sure that the quality and gauge of the wire matches the equipment.

3. Clean the nozzles and spools regularly to make sure they are free of foreign matter or burrs that could scratch the wire.

4. Reasonably adjust the tension of the tensioner according to the type and specification of the wire to ensure that the wire is subjected to proper tension during the winding process.

5. Regularly check the operating condition of the equipment to ensure that the equipment is in good working condition to avoid damage to the line caused by equipment failure.

6. Operators should be trained regularly to improve operating skills and safety awareness, to reduce the human factor caused by wire damage problems.

Customize 3530 24v DC BLDC Brushless Stator For Fpv UAV Drone Motor

What are the reasons for wire damage of brushless motor stator automatic winding machine? How to avoid wire injury? Vacuz above has made a brief description, I hope these tips can help you!

Имейл: sales@vacuz.com