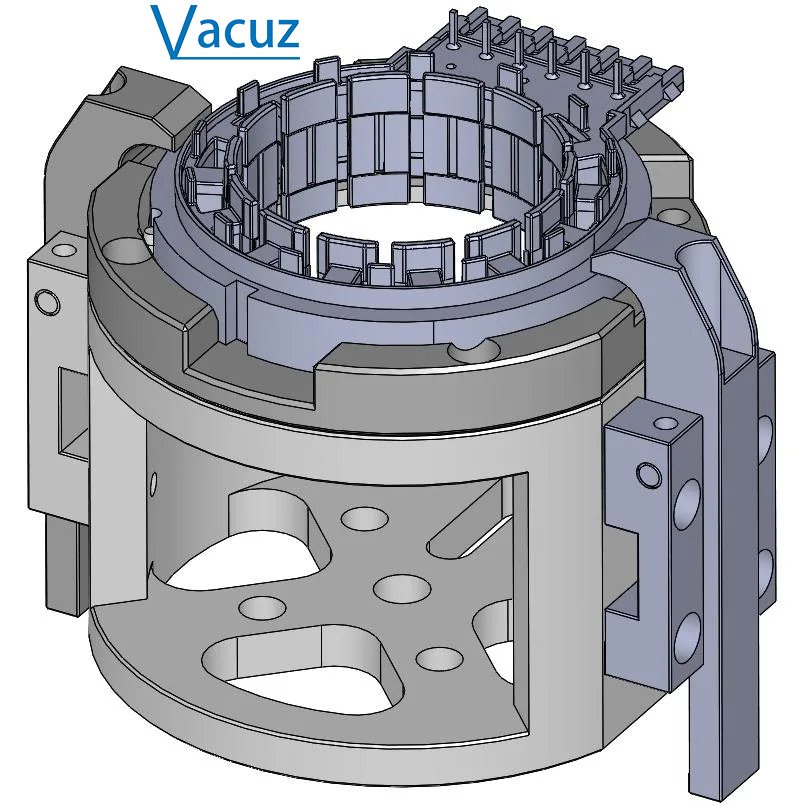

The brushless motor rotor external winding equipment, which is what we usually call the brushless motor external rotor winding machine, is suitable for stator products with the slot facing outward. This equipment has the following significant features and advantages. Vacuz will briefly introduce them to you!

Vacuz R&D Two Stations Automatic Inner BLDC Brushless Motor Stator Coil Needle Winding Machine Equipment

1. Highly automated: It realizes the integrated operation of manual loading and unloading and automatic clamping, winding, arranging, clamping and cutting. The whole process is easy and fast, which greatly improves work efficiency.

2. Strong and durable structure: The overall frame combines the advantages of sheet metal and aluminum profiles, has excellent shock absorption performance and stability, and can maintain extremely low vibration even at high speed.

3. Flexible fixture design: The fixture adopts modular design, fixed position and accurate positioning, easy replacement, and can quickly adapt to the production needs of various models of products.

4. Accurate and flexible control: The equipment is equipped with advanced servo motor control system and intuitive human-machine interface. Users can freely set parameters according to actual needs. It also has functions such as fault diagnosis and output recording. The winding speed is adjustable to meet the production requirements of diversified stator products.

5. Smooth and stable operation: By configuring high-quality parts such as precision guide rails, screw rods, cylinders, tensioners, etc., the smooth operation of the machine and the moderate tightness of the wire are ensured, effectively avoiding wire damage and derailment.

6. Low noise design: Provides a more comfortable working environment for staff.

In terms of improving winding efficiency and quality, we can start from the following key points:

1. Optimize the winding process: Design a simple and efficient winding process to reduce operational complexity and time cost, and improve overall production efficiency.

2. Use advanced control system: Combine PLC motion controller with servo system to achieve accurate control and further improve winding efficiency and stability.

3. Wire tension: Use tension sensors and control systems to ensure stable wire tension and avoid quality problems caused by too tight or too loose wires.

4. Real-time monitoring and adjustment: Continuously monitor the winding effect during the winding process, find and adjust problems in time, and ensure the stability of product quality.

5. Regular maintenance: Clean, lubricate and inspect the winding machine regularly to keep the equipment in good condition and extend its service life.

Vacuz R&D Two Stations Automatic Inner BLDC Brushless Motor Stator Coil Needle Winding Machine Equipment

In summary, the brushless motor outer rotor winding machine can fully meet the needs of efficient and high-quality winding with its many advantages and characteristics. In terms of controlling winding efficiency and quality, we need to comprehensively consider multiple key factors such as process design, control system, tension management, real-time monitoring and equipment maintenance.

Имейл: sales@vacuz.com