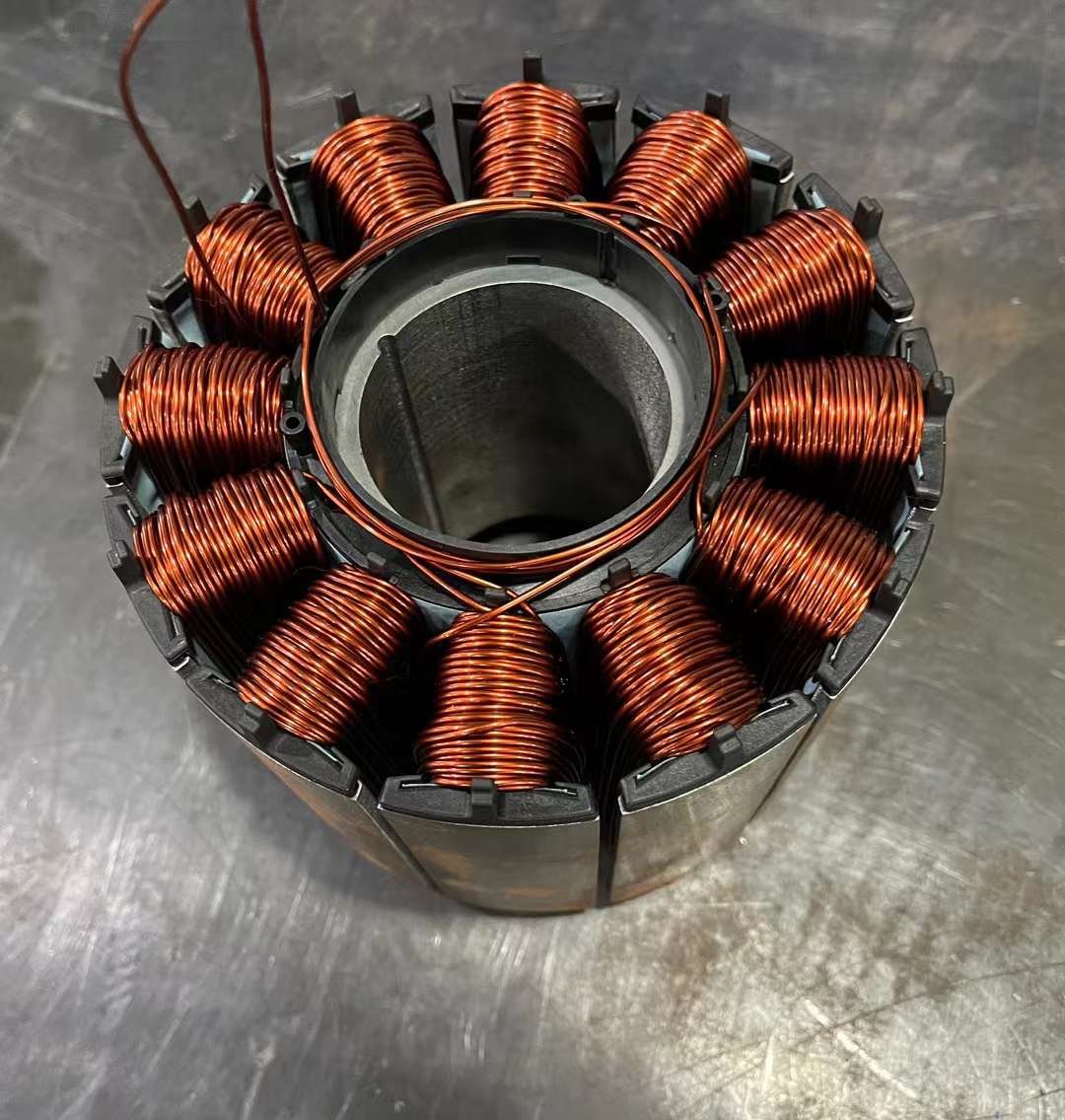

Common drones, traversing aircraft, aeromodels, plant protection machines, cooling fans and other brushless motor stator, most of the external winding, using a flying fork winding machine to complete the winding work, according to the size of the wire diameter, generally divided into winding fine wire and coarse wire, so the flying fork outside the winding machine to wind the coarse wire to pay attention to what? How to avoid the problem of coarse wire injury? The following Vacuz give you an introduction to it!

Vacuz Двойни станции Автоматичен BLDC безчетков дрон двигател Статорна намотка Летяща вилица Машина за навиване и опаковане на машина за вмъкване на хартия

In the process of coarse wire winding by flying fork external winding machine, you do need to pay special attention to several key aspects you mentioned to ensure that the wire is not damaged and the winding quality is up to standard.

Precautions and anti-injury measures when the flying fork external winding machine winding thick wire:

I. Precautions

1. Speed control: Coarse wire because of its larger diameter, in the winding process requires greater bending force. Therefore, the winding speed must be appropriately reduced to avoid excessive speed leading to excessive tension on the wire and breakage or damage.

2. Tension adjustment: reasonable tension is an important factor to ensure the quality of winding. According to the wire diameter and material of the thick wire, adjust the tension size to ensure that neither too large to pull off the wire, nor too small to cause the wire loose or knotted.

3. Adaptability of the equipment: the choice of flying fork outside the winding machine, you need to clarify the scope of application of its wire diameter. Ordinary models may not be able to handle large wire diameter winding, if necessary, should consider non-standard customized models to ensure that the equipment to meet the winding requirements.

4. Molds and stator frames: The precision and smoothness of the molds and stator frames directly affect the winding quality. Regular inspection and maintenance is required to ensure that there are no burrs or bumps and other factors that may scratch the wire.

5. Operation standardization: Operators should follow the standard operation procedure to avoid excessive impact or bending of the wire in the winding process, thus reducing the risk of wire injury.

Second, anti-injury measures

1. Choose the right equipment: in the purchase of flying fork outside the winding machine, you should inform the manufacturer in detail of the winding needs, including wire diameter size, material, etc., in order to get the right model recommended or non-standard customization services.

2. Accurately adjust the parameters: Before winding thick wire, you need to accurately adjust the speed, tension and other parameters according to the wire diameter and material, to ensure that the equipment is running in good condition to reduce the risk of wire injury.

3. Regular inspection and maintenance: Regularly check the accuracy and smoothness of key parts such as molds and stator skeletons, and repair or replace damaged parts in time. At the same time, comprehensive maintenance and upkeep of the equipment is carried out to ensure its long-term stable operation.

4. Training and guidance: Provide professional training for the operators to make them master the correct operation methods and skills. Provide necessary guidance and assistance in the operation process to avoid the problem of wire injury caused by improper operation.

5. Use of auxiliary tools: When winding thick wires, consider using auxiliary tools such as over-wire wheels, guides, etc., in order to reduce the tension and bending force on the wires, and further reduce the risk of wire injury.

Автоматична машина за навиване на статорни намотки за летящи вилици BLDC Brushless Drone

What should I pay attention to when winding thick wire with a flying fork external winder? How to avoid the problem of thick wire injury? To summarize, through careful attention and effective measures to prevent wire injury, the Flying Fork external winding machine can ensure that the wire is not damaged and the quality of the winding is up to standard when winding thick wire.

Имейл: sales@vacuz.com