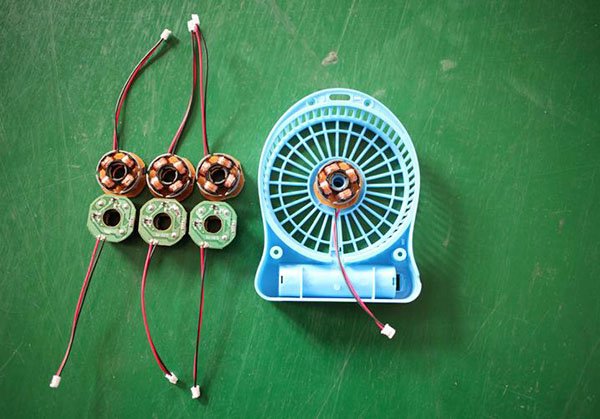

Brushless motor stator often have internal stator and external stator, because the design structure is different, so there are differences in the way the two winding, the following very brushless motor stator, to talk about the winding process and parameter characteristics it!

Brushless motor internal stator often uses internal winding method, also called needle type internal winding, divided into down hooking and up hooking methods, flexible winding, mainly through the needle bar drives the enameled wire up and down, the mold keeps rotating, to achieve the stator winding process.

Brushless motor internal winding machine features.

1. Adopt advanced control system at home and abroad, touch control mode, interface is clear at a glance, can monitor the operation of winding machine in real time, accurate control.

2. Flexible wire crossing and winding, can be wound at will according to the customer’s demand, the wire head and wire tail and crossing the same side and different side can be realized, the wire head and wire tail can be wound directly on the terminal, the wire head length can be set at will.

3. The whole machine is well configured, the base is made of sheet metal, the working table is made of stainless steel, the frame is made of aluminum alloy, the whole is beautiful, the screw, guide, cylinder, etc. are mostly made of high precision spare parts at home and abroad, the machine runs stably and does not shake and vibrate.

4. It can realize the process of automatic wire hanging, wire winding, wire arranging, wire pulling and wire cutting, etc. The automatic production method can be connected to the production line, which is easy and convenient.

5. Easy and quick to change the type, multiple models of products, just need to change the mold, it can be done quickly.

6. The internal winding machine has a wide range of application, can be applied to wire diameter between 0.1mm-1.3mm, the line is neatly arranged without any injuries.

Main parameters of brushless motor internal winding machine.

According to the stator product shape size, wire diameter, can be wound 2, 4 or 6 at the same time.

Suitable winding wire diameter: Φ0.08-Φ1.3mm.

Stator outer diameter: Φ20-130mm (beyond the range can be customized).

Stator inner diameter: Φ12-100mm.

Stator accumulation thickness: Φ5-80mm (beyond the range can be customized).

Winding speed: no-load speed can reach 1000R.P.M, depending on the size and wire diameter of the product.

The above is the winding process and characteristic parameters of internal winding machine, as the common winding method of internal winding stator, which is favored by the majority of users at present.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]