Brushless motor is widely used, its stator design is also a variety of internal winding, external winding, multi-slot, oblique slot, etc., so what are the common winding methods and considerations of brushless motor stator?

1. Manual winding, which is the more traditional way of winding the stator, in general, many manufacturers will use manual proofing, and some stator volume is not large, or some special irregular products will be used manually, is slower, some wire diameter is thicker easy to hurt the line, and then the fine line is very time-consuming multi-turn.

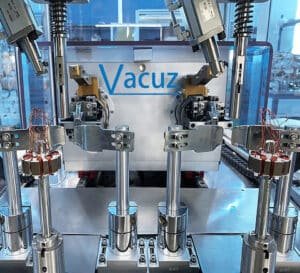

2. Flying fork winding machine or needle winding machine, which is currently more common stator winding method, applicable to a variety of external or internal winding stator products, universal, common machine is also more affordable, can be applied to large quantities of stator winding, fast, high efficiency, product winding consistent performance.

3. Stator production line, a few large manufacturers use this method, not only the stator winding, including wiring, dipping paint, etc. These links are all in one go, can save a lot of labor, the bad is that the cost is relatively high, the general small factory is difficult to accept.

Whether it is manual, or the use of automated equipment winding, we must pay attention to the quality of the stator winding, can not hurt the line, stacked lines, broken lines, etc., need to do a good job of stator detection, if there are problems, must be dealt with in a timely manner.

These are the common winding methods and considerations for brushless motor stator, I hope that in the choice of winding method, can help!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]