As a key equipment in modern motor manufacturing, the integration of precision and intelligence of the fully automatic motor stator winding machine has undoubtedly brought revolutionary improvement to motor production. So how is the precision and intelligence of the fully automatic motor stator winding machine reflected? In what aspects? The following is a further expansion and refinement of the relevant content by Vacuz, aiming to show its deeper advantages and application value.

Custom High Quality Drone And Rc Uav Bldcl Motor Core Lamination Fan Brushless Stator Laminated Electric Motor Stator Core

1. In-depth analysis of precision embodiment:

1. The pursuit of high-precision mechanical structure

a. Precision ball screw and linear guide: The use of these core components not only ensures high-precision positioning during the winding process, but also greatly improves the stability and durability of the equipment. Through fine processing and assembly processes, the repeated positioning accuracy of the equipment has reached ±0.01mm, laying a solid foundation for the precision winding of the motor.

b. Real-time monitoring of laser displacement sensor: The application of this innovative technology enables the position of the copper wire in the winding process to be monitored in real time and accurately. Once the deviation exceeds the preset range, the equipment can quickly adjust the wiring mechanism to ensure the consistency of winding accuracy.

2. Fine control of tension and position control

a. Strict control of tension fluctuations: Tension is a key factor that cannot be ignored in the winding process. Through the advanced tension control system, the equipment can control the tension fluctuation within ±3%, effectively avoiding the problem of wire breakage or coil loosening, thereby ensuring the efficiency and life of the motor.

b. The ultimate pursuit of winding position error: Accurate control of winding position is crucial to the electromagnetic performance of the motor. The equipment strictly controls the winding position error within ±0.02mm through high-precision position sensors and control systems, effectively avoiding the problem of magnetic circuit asymmetry and improving the electromagnetic performance of the motor.

2. Comprehensive display of intelligence:

1. Flexible and efficient intelligent control system

a. Application of PLC or motion controller: These advanced control systems enable the equipment to support multi-speed and multi-mode switching, meeting the needs of different motor stator winding. At the same time, the preset process parameters (such as number of turns, number of layers, pitch) greatly simplify the operation process and improve production efficiency.

b. Friendly interaction of human-machine interface: Through the intuitive and easy-to-operate human-machine interface, users can monitor and adjust the operating parameters of the equipment in real time. At the same time, the data storage and call function makes the operation of the equipment more convenient and efficient.

2. Integration and expansion of automation functions

a. Integration of automatic winding, wire cutting, and wire arrangement functions: The implementation of these automation functions greatly reduces the need for manual operation and improves the stability of production efficiency. At the same time, the support of functions such as cross-bevel slot and multi-wire winding enables the equipment to adapt to more complex winding needs.

b. Improvement of fault detection and early warning system: By integrating a full range of quality inspection systems, the equipment can monitor the winding process in real time, and promptly discover and handle defects such as missing wires and overlaps. At the same time, the fault warning display function allows users to easily find the cause of the fault and take corresponding measures to protect the equipment and achieve interruption and continuation.

3. Synergistic advantages of precision and intelligence

1. Significant improvement in product quality

a. Precision winding technology reduces electromagnetic noise: Through precision winding technology, the equipment can significantly reduce the electromagnetic noise of the motor and improve the energy efficiency level, thereby meeting more stringent environmental protection and energy efficiency requirements.

b. Intelligent system reduces human errors: The application of intelligent systems enables the equipment to greatly reduce the impact of human errors during operation and improve product consistency and reliability. The significant reduction in defective rates further enhances the market competitiveness of products.

2. Effective reduction in manufacturing costs

a. Automated production reduces labor costs: Through the application of automated production lines, equipment can replace a large number of manual operations, thereby reducing labor costs. At the same time, efficient production processes also improve material utilization and reduce long-term operating costs.

b. Precision wiring and tension control reduce material waste: Through precise wiring and tension control technology, the equipment can minimize material waste and improve production efficiency and economic benefits.

3. Flexible response to industry trends

a. Compatible with multi-field requirements: The equipment can be compatible with the miniaturized and high-performance motor requirements in new energy vehicles, drones, home appliances and other fields, showing strong adaptability and flexibility.

b. Support non-standard customization: In response to the development needs of special winding processes, the equipment can provide non-standard customization services, quickly respond to market changes, and meet customers’ personalized needs.

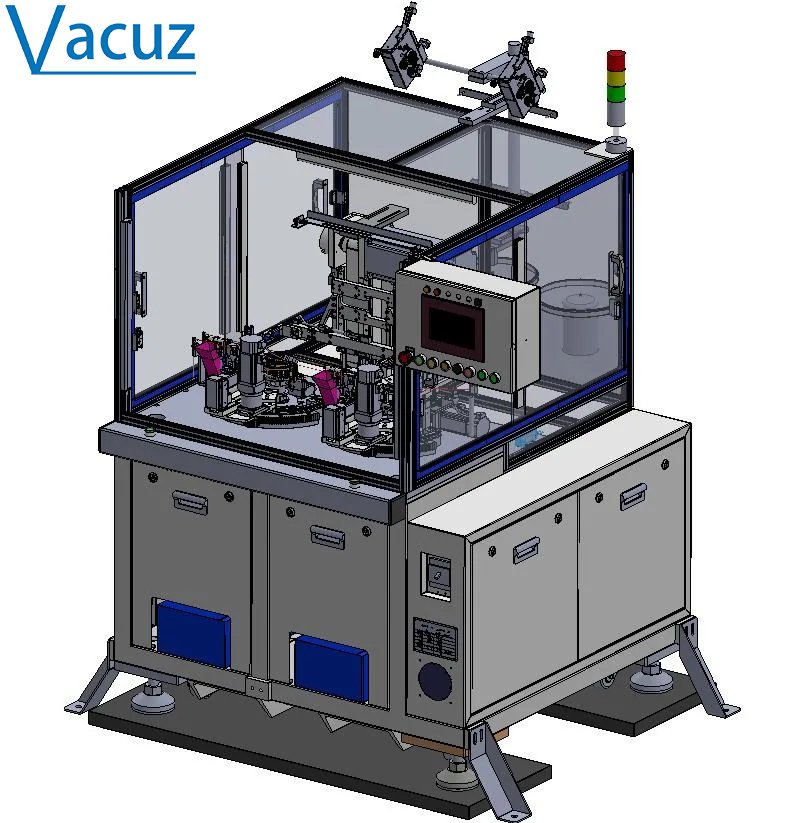

Vacuz R&D Two Stations Automatic Inner BLDC Brushless Motor Stator Coil Needle Winding Machine Equipment

In summary, the precision and intelligence of the fully automatic motor stator winding machine not only improves the quality and production efficiency of the product, but also reduces the manufacturing cost and adapts to the development of industry trends. In the future, with the continuous advancement and innovation of technology, it is believed that such equipment will play a more important role in the field of motor manufacturing.

E-mail: sales@vacuz.com