During the operation of the micro motor rotor production line, some common minor faults may be encountered. If these faults are not handled in time, they may affect the normal operation of the production line. The following is a detailed summary of these common minor faults and their maintenance measures by Vacuz, hoping to help everyone!

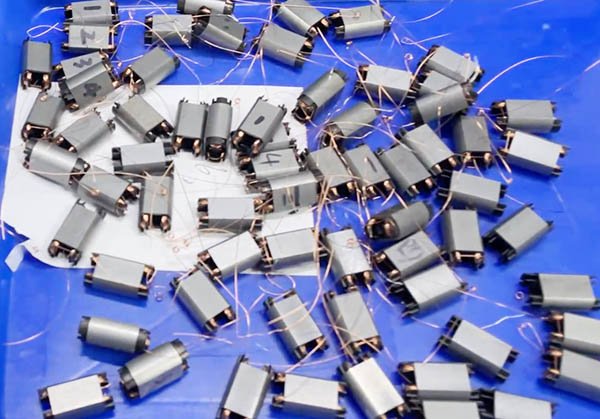

micro motors

1. Analysis of common minor faults

1. Power supply problem:

The power line may be broken or short-circuited, resulting in the equipment failing to start normally or unstable during operation.

2. Wear of equipment components:

After long-term use, some key components of the equipment (such as bearings, gears, etc.) may wear out, thereby affecting the accuracy and operating performance of the equipment.

3. Sensor failure:

The sensor may lose its effectiveness due to coverage by pollutants such as dust and oil, resulting in the inability of the equipment to accurately detect the status of the rotor.

4. Gas supply or electrical connection problems:

Insufficient gas supply or aging of electrical connection lines, poor contact, etc. may cause the equipment to fail to operate normally.

5. Rotor quality problems:

The selection of rotor materials or defects in the manufacturing process may cause rotor imbalance, substandard resistance values, etc., thereby affecting the overall performance of the motor.

2. Detailed explanation of maintenance measures

1. Power line inspection:

Regularly check the connection status of the power line to ensure that there is no disconnection or short circuit. At the same time, monitor the stability of the power supply voltage to prevent voltage fluctuations from damaging the equipment.

2. Equipment component lubrication and replacement:

Regularly lubricate the key components of the equipment such as bearings and gears to reduce wear. For components with severe wear, they should be replaced in time to ensure the accuracy and operating performance of the equipment.

3. Sensor cleaning and calibration:

Regularly clean the sensor to remove dust, oil and other pollutants covering it. At the same time, calibrate the sensor to ensure that it can accurately reflect the status of the rotor.

4. Air source and electrical connection inspection:

Ensure that the air source is adequately supplied, and regularly check the status of the electrical connection line to prevent aging, poor contact and other problems. For aging electrical connection lines, they should be replaced in time.

5. Rotor quality monitoring:

Strengthen the quality control of rotor materials and production processes to ensure that the quality of the rotor meets the requirements. At the same time, regularly inspect the rotor to detect and deal with quality problems in a timely manner.

6. Daily care and maintenance:

Maintain the equipment regularly, including cleaning, lubrication, tightening, etc. At the same time, establish a complete maintenance record to track and analyze the use of the equipment.

7. Training and skills improvement:

Regularly organize operators to conduct training and technical exchanges to improve their operating skills and maintenance awareness. At the same time, encourage operators to actively learn new technologies and methods to improve the efficiency and maintenance level of equipment.

Produktionslinje for børstemotorens statorspole

In summary, the maintenance measures of the micro motor rotor production line should comprehensively cover power lines, equipment components, sensors, gas sources and electrical connections, rotor quality and other aspects. Through regular inspection, cleaning, lubrication, replacement of components, calibration of sensors and other measures, the stable operation of the production line can be ensured and the service life can be extended. At the same time, strengthening operator training and technical exchanges is also the key to improving the level of equipment maintenance.

E-mail: sales@vacuz.com