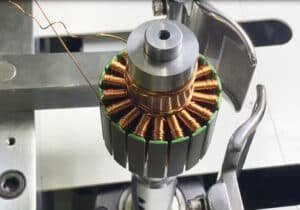

With the continuous development of the motor industry, motor manufacturers have entered the intelligent production mode, for example, before the winding work is basically done by hand, now there is an automatic winding machine, not only greatly improve production efficiency, and winding effect is also better.

Spolevikling

Automatic winding machine is intelligent machinery and equipment, although as long as the debugging settings are set up, it is easy to use, but debugging is still relatively troublesome, without professional training of staff or difficult to handle, so what are the important parameters in the common debugging?

1. Start winding position settings

Is the automatic winding machine to start winding the starting position, and the coil head and type have a close relationship, commonly used to measure the specific value of the control system measurement function; of course, you can also use manual measurement, select a fixed reference point, using a ruler to measure, pay attention to is to determine the direction of the coil winding.

2. Enameled wire specification setting

General stator winding are used enameled wire, different enameled wire specifications, wire diameter is different, different wire diameter on the automatic winding machine line effect is different, wire diameter more than 1.0mm, or less than 0.1mm, more test the accuracy of the automatic winding machine, enameled wire specifications must be set to meet the requirements to ensure the effect of winding and quality.

3. Tensioner tension setting

Automatic winding machine tension setting is also very important, generally speaking, there are corresponding tension values, can not be set randomly, otherwise it is easy to lead to line breakage, or the line is not tight.

4. Winding line width setting

Automatic winding machine winding width, refers to the distance between the beginning of each slot winding position to the end of the winding, can respond to the skeleton winding length required, set to pay attention to some small deformation and other factors, the use of comprehensive measurement is better.

BLDC-spole vikling

These are the common parameters of the automatic winding machine debugging method, master these basic knowledge, in order to better use the winding machine, winding a more beautiful coil!

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com