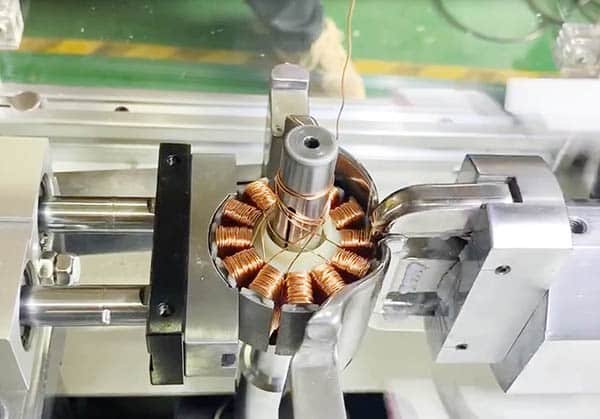

Brushless motor stator winding, generally can be divided into single-wire winding or multi-wire parallel winding method, so what is the difference between single-wire and multi-wire stator parallel winding? What are the requirements for the winding machine equipment? The following Vacuz briefly introduce it to you! I hope to help you!

Brushless Motor Winding

These two winding methods in the performance of the motor, the cost and the requirements of the winding machine equipment, there are significant differences.

1. In terms of performance, single-wire winding is suitable for some low-power, miniaturized motor scenarios due to its simple structure and excellent performance at low power, as well as easy to realize miniaturization. On the other hand, multi-wire parallel winding provides higher torque and efficiency at the same power, as well as higher fault tolerance, which is more suitable for high power and demanding scenarios.

2. From the cost point of view, the simple structure of single wire winding makes it relatively low cost, while multi-wire parallel winding requires more coils and ESCs to output more current, and the cost will naturally increase accordingly.

3. In the requirements of the winding machine equipment, multi-wire winding on the equipment configuration requirements, including a variety of precision spare parts and stable frame structure, etc., at the same time, the debugging process is also more complex. While single-wire winding on the equipment requirements are relatively low, the commissioning process is also relatively simple.

In addition, you also mentioned the influence of slot and wire diameter, stator height and other factors on the two winding methods, which are more practical and important considerations.

Vacuz børsteløs motorspole

What is the difference between single-wire and multi-wire stator winding? What are the requirements for the winding machine equipment? Overall, the choice between single-wire stator and multi-wire parallel winding in brushless motors needs to be considered according to the specific application scenarios and needs.

E-mail: sales@vacuz.com