The fully automatic brushless stator winding loading and unloading process, through the combination of automation and modular design, has brought unprecedented efficiency and accuracy to motor production. The following is a further expansion and refinement of the relevant content by Vacuz, aiming to more comprehensively demonstrate its characteristics and advantages, and I hope it can help everyone!

Produktionslinje for børstemotorens statorspole

In-depth analysis of the characteristics of loading and unloading processes:

1. Seamless docking of automated integration

a. Collaborative operation of manipulators and conveyor belts: The use of advanced manipulators or conveyor belt technology realizes the automatic loading and unloading of stators on the production line, greatly reducing manual intervention and improving the continuity and stability of production. At the same time, these automated equipment can be seamlessly connected with existing automated production lines to realize full process automation from winding to testing, further improving production efficiency.

b. Multi-station parallel operation design: Through careful layout and design, multiple stations can be operated in parallel, further shortening the production cycle and improving overall production capacity.

2. Flexible and efficient modular design

a. Independent modular design of fixture: The fixture adopts an independent modular design, which not only supports fast changeover and adapts to the needs of stator winding of different specifications, but also greatly simplifies the maintenance and maintenance of the equipment. This design allows operators to easily replace fixtures without complex adjustments or calibrations.

b. Standardized mold processing: The mold is standardized and easy to replace and disassemble. This not only shortens the changeover time, but also reduces the production error caused by improper mold replacement.

3. Stable and reliable high-precision positioning

Modular setting of fixture and laser displacement sensor: The fixture adopts modular setting, fixed position and accurate positioning, ensuring the stability of the stator during the winding process. At the same time, the real-time monitoring function of the laser displacement sensor can timely detect and correct the deviation of the stator position to ensure the consistency of winding accuracy.

Comprehensive display of the advantages of loading and unloading technology:

1. Substantial improvement in production efficiency

a. Continuous and uninterrupted winding capability: Thanks to the advantages of automated integration and modular design, the equipment has the ability to continuously and uninterruptedly wind, greatly shortening the production cycle. At the same time, the multi-station parallel operation design further improves production efficiency, significantly improving overall production capacity.

b. Automatic line change and automatic cut-off functions: The realization of these functions reduces the burden on operators, allowing them to focus on more important work. At the same time, it also further improves production efficiency, allowing products to go to market faster.

2. Reliable guarantee of product quality

a.High-precision positioning and modular design: These design features reduce the impact of manual errors and significantly improve product consistency. The defective rate is controlled below 0.1%, further enhancing the market competitiveness of the product.

b.Automated loading and unloading to avoid damage: The adoption of automated loading and unloading technology avoids the risk of stator damage during handling, thereby ensuring the winding quality. This is of great significance to improving the overall performance of the product and extending its service life.

3. Effective reduction of manufacturing costs

a. Substantial reduction in labor costs: The application of automated production lines enables each device to replace 3-5 workers, thereby significantly reducing labor costs. This is a considerable saving for enterprises.

b. Significant improvement in material utilization: By optimizing the production process and adopting advanced material utilization technology, the material utilization rate has been increased to more than 98%. This not only reduces material waste, but also reduces long-term operating costs.

4. Flexible response to industry trends

a. Compatible with multi-field needs: The equipment is compatible with the needs of miniaturized and high-performance motors in the fields of new energy vehicles, drones, home appliances, etc., showing strong adaptability and flexibility. This enables enterprises to respond to market changes more quickly and seize new development opportunities.

b. Support non-standard customization: In response to the development needs of special winding processes, the equipment can provide non-standard customization services. This enables enterprises to meet the personalized needs of customers and further expand their market share.

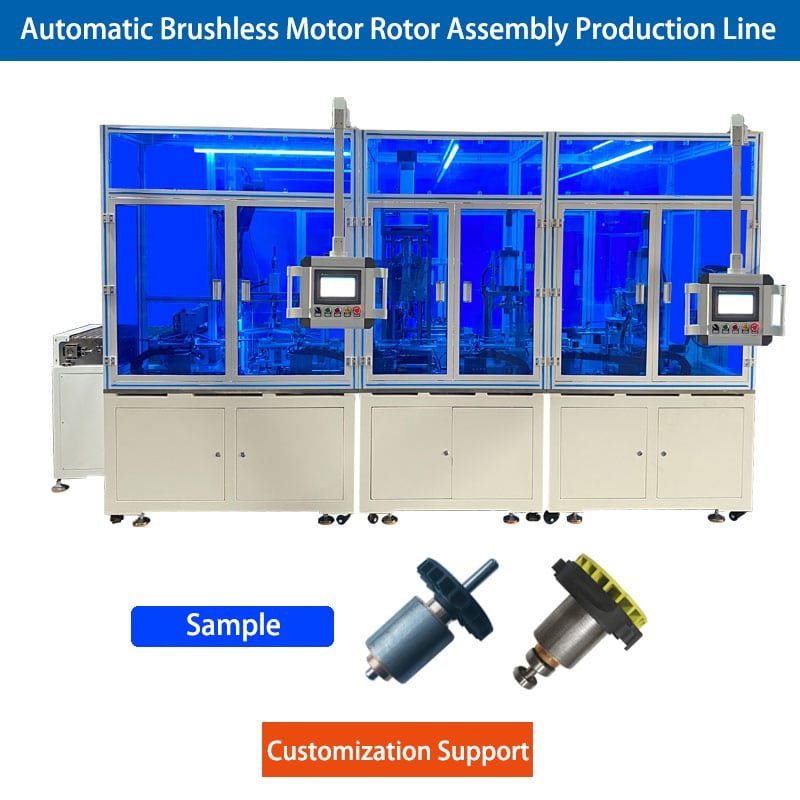

Automatisk produktionslinje til montering af børsteløs motorrotor

In summary, the fully automatic brushless stator winding loading and unloading process achieves efficient and accurate production through the combination of automation and modular design. Its characteristics and advantages not only improve product quality and production efficiency, but also reduce manufacturing costs and adapt to the development of industry trends. In the future, with the continuous advancement and innovation of technology, it is believed that this type of process will play a more important role in the field of motor manufacturing.

E-mail: sales@vacuz.com