The efficiency of a brushless motor stator winding machine is closely related to factors such as mechanical structure, stator parameters, control system, mold precision, tension control, and debugging technology. Evaluating the quality of a winding machine requires comprehensive consideration of efficiency, quality, stability, applicability, and maintenance costs. Below, Vacuz will give you a brief introduction!

1. Mechanical Structure and Configuration:

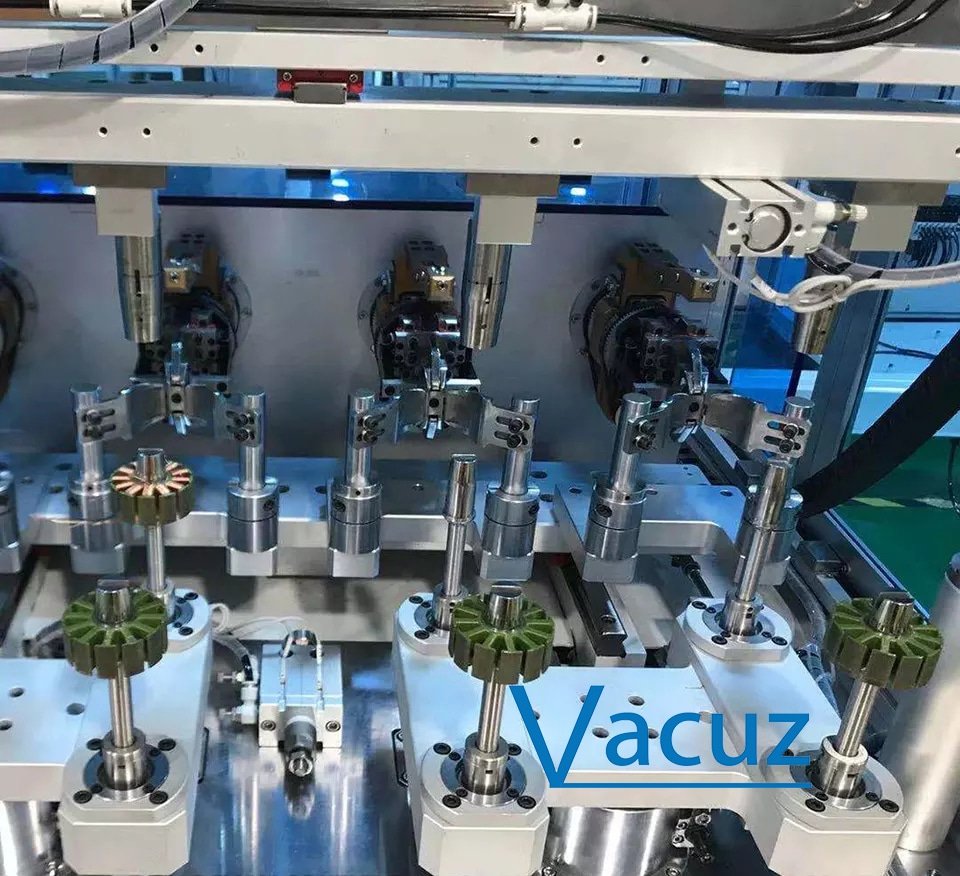

a. Basic Architecture: The chassis, worktable, and frame of the winding machine are crucial to its operational stability. A sheet metal base, aluminum alloy frame, and stainless steel worktable are typically used; this combination ensures the machine remains stable and reliable even at high speeds.

b. Motion Components: The performance of moving parts such as motors, cylinders, and lead screws directly affects the winding speed and accuracy. Especially during high-speed internal winding or precision wiring, selecting high-quality imported servo motors and premium cylinders and lead screws is key to ensuring winding speed and accuracy.

c. Auxiliary Accessories: The proper selection and use of accessories such as tensioners, felt, and wire nozzles also ensures the tension of the enameled wire, preventing wire breakage or damage during high-speed winding.

2. Stator Parameters:

a. Dimensional Parameters: The outer diameter, inner diameter, and stack thickness (height) of the stator directly determine the required winding equipment model. Different size ranges may require different equipment.

b. Wire Diameter Influence: The thickness of the wire directly affects the winding speed. For micro-sized brushless motors, the wire diameter is generally between 0.08mm and 1.3mm. The finer the wire diameter, the faster the winding speed can be set; conversely, the winding speed needs to be reduced accordingly when the wire diameter is thicker.

c. Multi-Wire Winding and Slots: When winding multiple strands of copper wire in parallel, the speed decreases as the number of copper wires increases. Furthermore, the smaller the slot distance, the faster the winding speed needs to be adjusted to avoid scratching or breaking the enameled wire.

d. Shape and Orientation: The shape and slot orientation of the stator also affect the operating efficiency of the winding machine. For example, skewed slot stators may require special winding methods.

3. Control System:

Accurate control of a servo drive system relies on the cooperation of a high-quality controller and servo motor. Only with such a combination can accurate control be achieved during the winding process.

The control system also needs parameter setting functions to adjust parameters such as winding speed and number of turns according to stator parameters and winding requirements.

a. Die Precision:

The machining precision and installation accuracy of the die directly affect the winding effect. Higher die precision results in smoother and more standardized winding.

Die design also needs to consider the accuracy of stator core frame machining, as well as the positioning accuracy of the inner winding needle rod, outer winding guard plate, and stator rod.

b. Debugging Technology: Professional debugging and after-sales service are also key to ensuring stable machine operation and meeting customer needs. Through professional debugging, the machine can be adjusted to a good state, thereby achieving high-speed and stable production.

Indicators for Evaluating the Quality of a Winding Machine

1. Efficiency:

Evaluate the number of coils or the length of coils wound by the winding machine per unit time. Higher efficiency indicates a stronger production capacity of the winding machine.

2. Quality:

Observe whether the coils wound by the winding machine are neat and tight, and whether there are any broken or damaged coils. A high-quality winding machine should ensure stable and reliable winding quality.

3. Stability:

Assess whether the winding machine experiences malfunctions or performance degradation during long-term operation. A stable winding machine should ensure the continuity and reliability of the production process.

4. Applicability:

Consider whether the winding machine is suitable for winding stators of different specifications and shapes. A versatile winding machine should meet the diverse needs of different customers.

5. Maintenance Costs:

Assess the maintenance costs and replacement costs of vulnerable parts for the winding machine. A winding machine with low maintenance costs should reduce the company’s long-term operating costs.

What factors affect the efficiency of a brushless motor stator winding machine? How to evaluate the quality of a winding machine? Vacuz has provided a simple explanation above, and we hope this information is helpful!