The budget for purchasing a brushless motor stator winding machine ranges from tens of thousands to hundreds of thousands of yuan, depending on the equipment configuration, level of automation, and production needs. Below are price examples for different types of equipment, which Vacuz will briefly explain to help you understand!

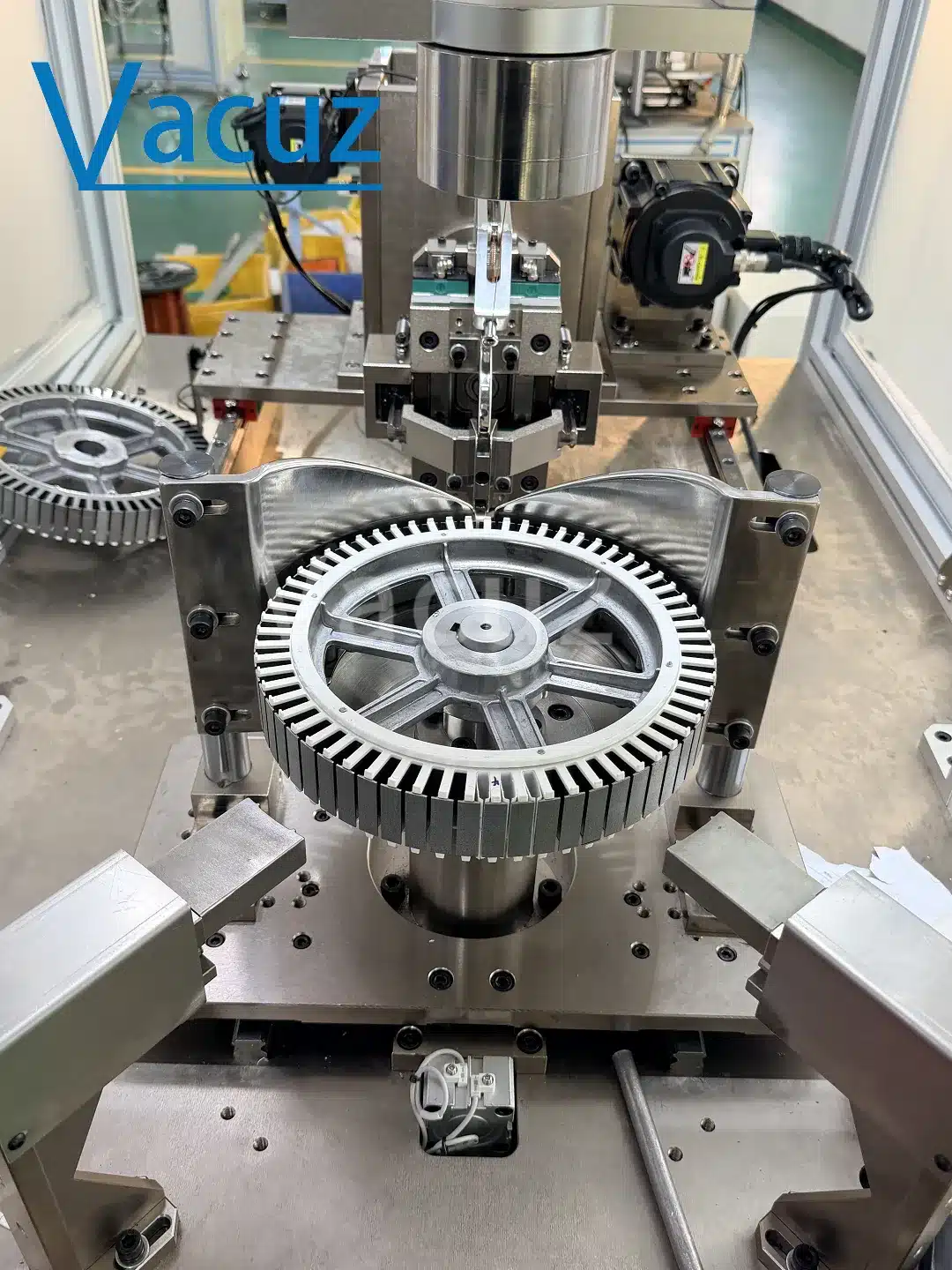

Basic Model: Fully automatic dual-station brushless stator winding machine, priced at approximately 100,000-150,000 yuan, suitable for small-scale production or budget-constrained scenarios.

Mid-range Model: Four-station internal winding machine, priced at approximately 150,000-200,000 yuan, featuring a high degree of automation and winding efficiency, suitable for medium-scale production.

High-end Model: Six-station high-speed motor winding machine, priced as high as 200,000-250,000 yuan, suitable for large-scale, high-precision production needs.

When selecting a winding machine, consider the following factors:

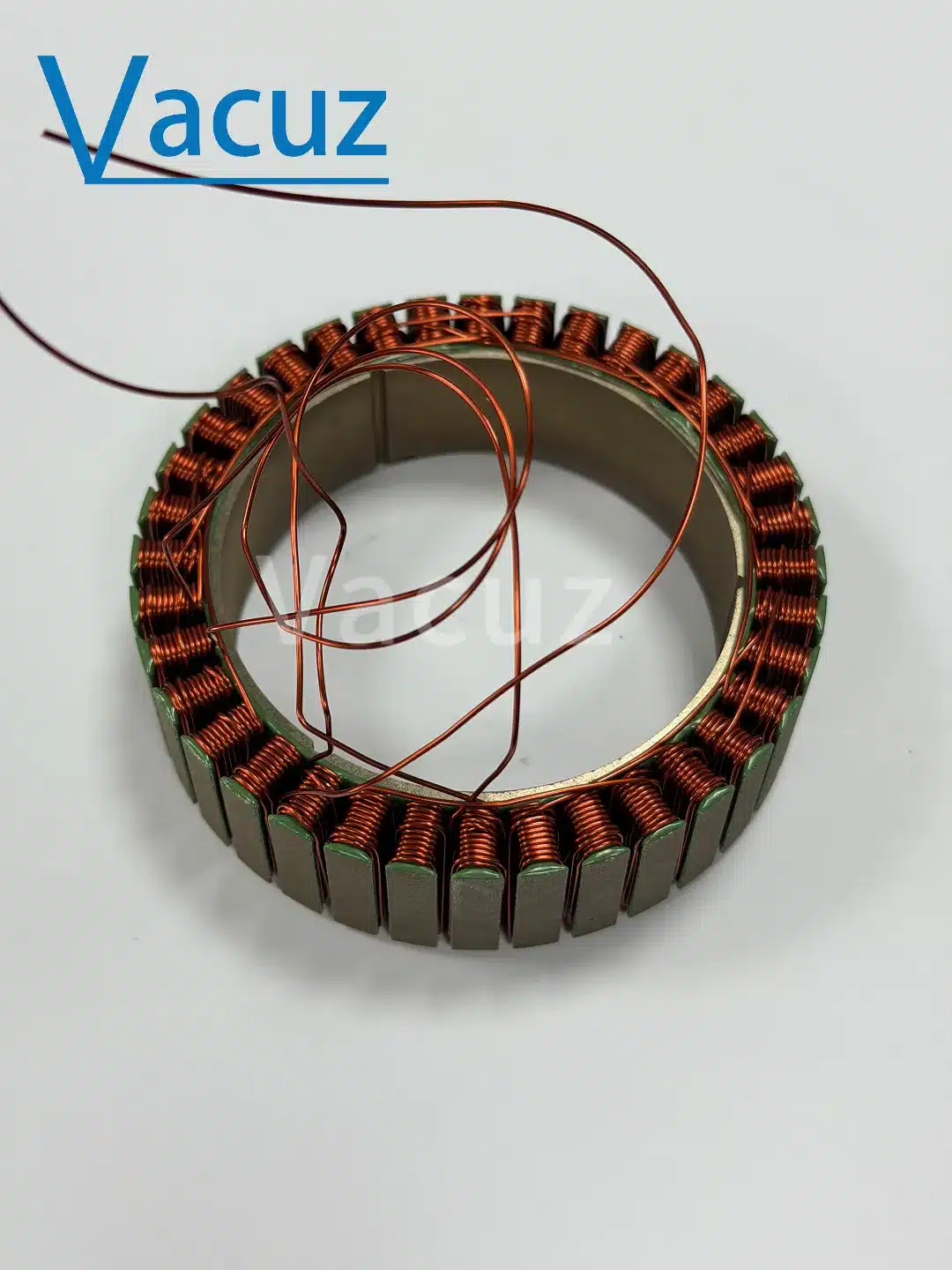

1. Stator parameters:

Outer and inner diameter: The number of stations and die size of the winding machine must match the outer and inner diameters of the stator. For example, stators with an outer diameter exceeding 140mm typically require a single-station machine.

Stack Thickness: For stators with high stack thickness, the pin oscillation method and wire guide method of the winding machine must be considered to avoid wire scraping or breakage.

Slot Direction: Stators with slots facing inward require an internal winding machine, while stators with slots facing outward are suitable for an external winding machine.

2. Wire Diameter and Winding Method:

Wire Diameter: Fine wires (e.g., around 0.1mm) can be wound using a high-speed winding machine, while thicker wires (e.g., exceeding 1.0mm) require a tension control system and a precision winding machine.

Multi-Wire Winding: If multiple wires need to be wound simultaneously, equipment with precise tension control and synchronous winding functions must be selected to ensure winding uniformity.

3. Production Requirements:

Winding Speed: Select an appropriate winding speed based on production scale. High-speed winding machines can improve production efficiency, but equipment stability must be ensured.

Automation Level: Highly automated equipment can reduce manual operation and errors, but the price is relatively higher.

4. Equipment Configuration and Performance:

Tension Control System: Ensures stable tension during winding, preventing wire breakage or coil loosening.

Wire Laying System: A precise wire laying system ensures neat wire arrangement, improving winding quality.

Wire Cutting Device: Automatic wire cutting improves production efficiency and reduces manual intervention.

5. Manufacturer Strength and After-Sales Service:

Manufacturer Scale: Choosing a reputable and large-scale manufacturer ensures equipment quality and after-sales service.

After-Sales Service: Includes equipment installation and commissioning, training, maintenance, and spare parts supply. Good after-sales service reduces the impact of equipment failures on production.

How much budget is needed to buy a brushless motor stator winding machine? What factors should be considered when choosing a winding machine? Vacuz has provided a simple explanation above, hoping this information will be helpful!