Transformer winding machine is a special equipment used to wind transformer coils. The following is the classification and characteristics of transformer winding machine.

Classification of transformer winding machines:

In the process of transformer coil production, according to the voltage level and capacity of the transformer to divide the winding equipment, there are automatic line winding machine for winding distribution transformers high and low voltage coils and foil winding machine for large power transformer coils vertical winding machine and horizontal winding machine.

Transformer winding machine is mainly used in transformer high and low voltage winding winding processing, mainly divided into automatic, CNC two categories, CNC models are currently more applied equipment, transformer winding machine after many generations of improvement and development, in function and processing capacity have been rapid development.

Characteristics of transformer winding machine:

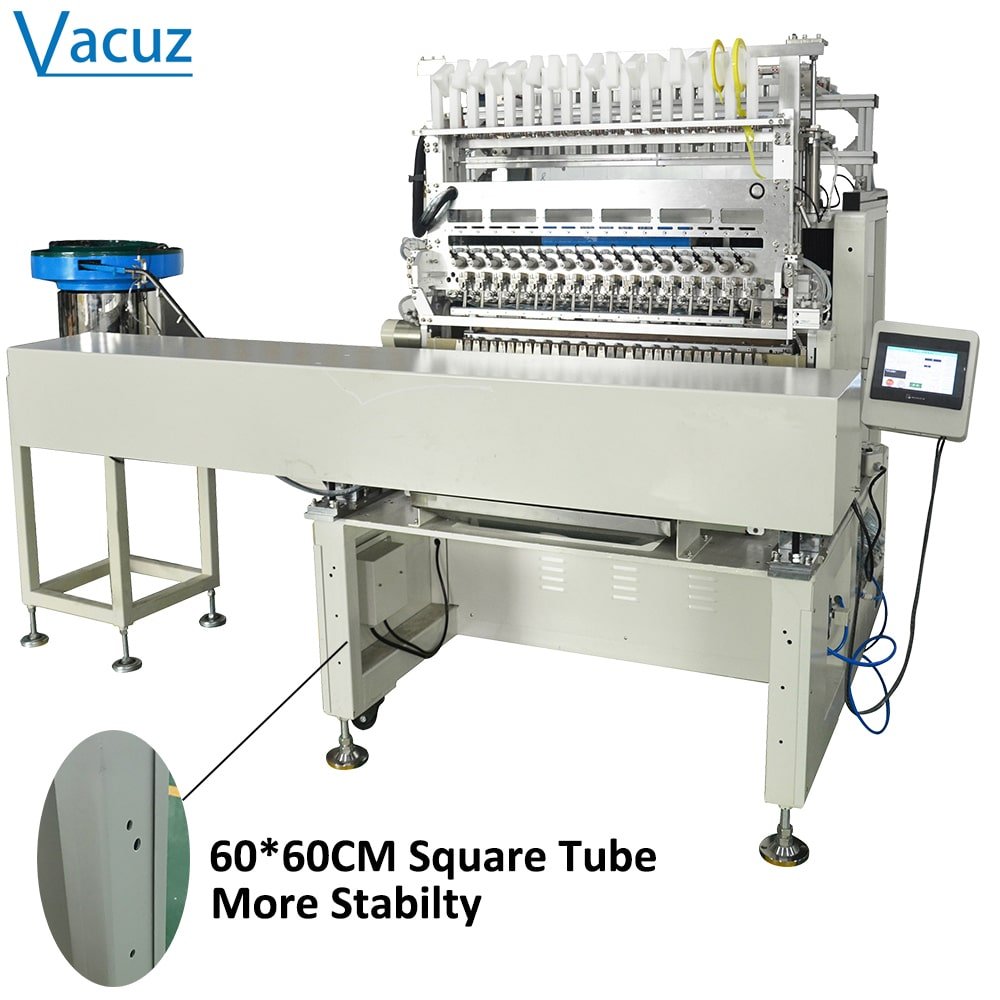

Transformer winding machine structure mainly consists of the body, frame, spindle mechanism and tailstock support, machine base and other components, transformer coils have a certain weight, while processing needs to withstand the external force of knocking plastic, so the winding machine body, frame with strong bearing capacity of steel, according to the size of the processing capacity of the model is divided into small, medium and large, the carrying capacity is also different.

Spindle system is an important part of the transformer winding machine, the motor power through multi-stage deceleration to expand the torque output to meet the processing of transformer winding, the general use of motors, reducer mechanism and other structural configuration, variable speed mechanism is usually used to achieve the motor frequency conversion or gear switching of the reducer.

Transformer winding machine data storage segment 0 ~ 999 steps of the same, can be high-speed forward and reverse winding, the number of turns accurate, the use of problems occurring in the data automatically saved, CNC can monitor the production status, simple settings, easy to operate.

WhatsApp/Wechat: +86 13075286997

E-Mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]