Brushless motor rotor can be assembled manually or by semi-automated equipment, or by automated production lines, relatively speaking, automated assembly is more advantageous, but also in line with current production trends, so brushless motor rotor automatic assembly process and the advantages and characteristics of how to Vacuz to introduce!

Brushless motor rotor automatic assembly process.

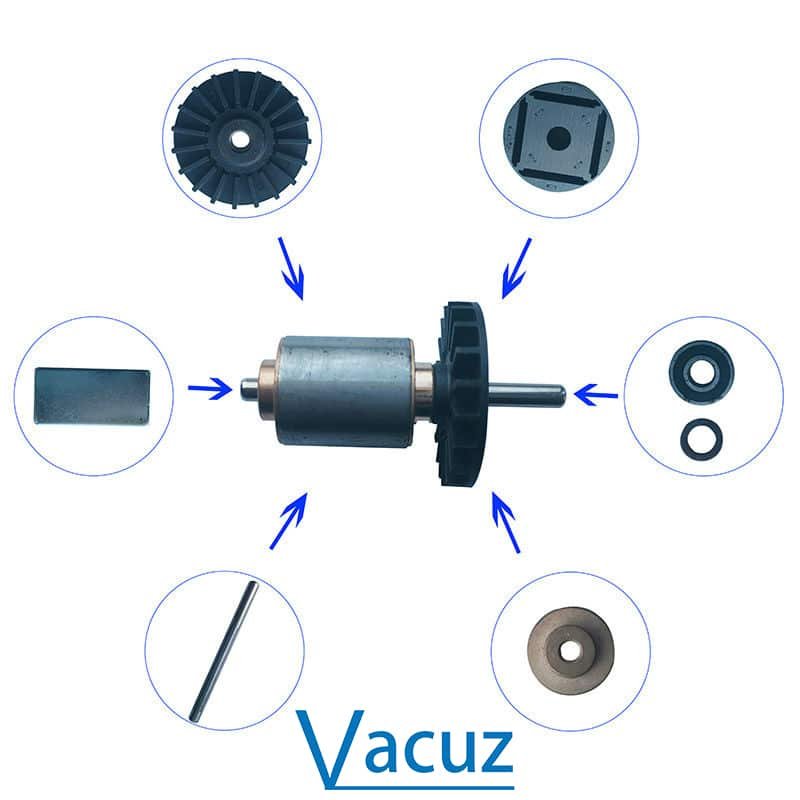

Brushless motor rotor automatic assembly, mainly contains: automatic core loading, magnetic sheet into the core, shaft into the core, wind blade assembly, dynamic balance test, visual inspection, bearing press-fit process, automatic under the material and other processes. The whole process can be monitored in real time and controlled by microcomputer at a glance.

Brushless motor rotor automatic assembly advantages.

1. shaft-in-core station configuration force and displacement detection to ensure product quality.

2. 4pcs magnets are loaded into the core at one time, and the height of the magnets is guaranteed by the electric cylinder with displacement sensor; and the system is equipped with Hall sensor, which can judge and prevent errors on the N\S poles of the magnets.

3. bearing press fitting station configuration force and displacement detection, to ensure product quality.

4. Sweep the code for each product and record the parameters of the production process, product data can be traced.

The above is the automatic assembly process and advantages of brushless motor rotor, the production of rotor is a number of strict procedures, only in accordance with the normal process, to ensure that the rotor assembly qualified.

WhatsApp/Wechat: +86 13075286997

E-Mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]