Brushless water pump motor stator winding equipment selection is very important, a good winding equipment, in order to ensure the quality and effectiveness of the winding, then how to choose the stator winding equipment for brushless water pump motor? How to improve the winding yield? The following Vacuz give you an introduction!

First, the pump brushless motor stator winding equipment selection

1. Stator type and parameters of the clear

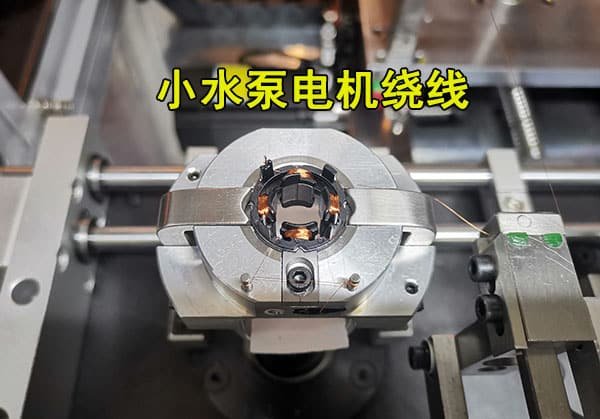

a. Type identification: the first to identify the internal winding stator or other types, such as 4-slot small stator and 6-slot stator, which directly determines the choice of winding machine.

b. Parameter Consideration: Slot direction, outer diameter size and wire diameter size are the parameters to focus on when choosing the winding machine. For example, the slot inward stator is suitable for needle winding machine, while the outer diameter is too large or wire diameter has special requirements may require customized equipment.

2. Selection of equipment type and configuration

a. Needle Winding Machine: Suitable for inward winding of stator, the enameled wire is driven by needle bar to run at high speed, suitable for stator with moderate outer diameter and fine wire diameter.

b. Non-standard winding machine: for special needs, such as large outer diameter, high stack thickness or special row of precision stator, customized equipment is more appropriate.

c. Equipment configuration upgrades: the use of high-quality servo motors, electric drives, screws, rails, cylinders and tensioners and other components, can effectively improve the quality and efficiency of winding.

3. Balance production efficiency and cost

Under the premise of meeting production requirements, select cost-effective equipment to ensure economic efficiency.

Second, improve the yield rate of winding measures

1. Optimize the winding process

According to the specific parameters of the stator and winding requirements, accurately adjust the winding process to ensure a stable and reliable process.

2. Selection of high-quality materials

Select high-quality enameled wire and other winding materials to reduce the risk of poor winding from the source.

3. Enhance equipment maintenance

Regular maintenance and repair of the winding machine to ensure that the equipment is in good working condition. Timely detection and treatment of equipment failure to avoid affecting production.

4. Improve staff skills

Provide professional training to employees who operate the winding machines to improve their operating skills and quality awareness. Ensure that employees are able to master the operation of the equipment and precautions.

5. Implement strict quality control

Set up quality check points in the winding process and use testing tools to check the quality of the winding. To deal with and correct the problems found in a timely manner to ensure product quality.

6. Introduce automation and intelligent technology

Use automation and intelligent technology to improve the precision and stability of winding. For example, the use of automated winding machines and intelligent detection systems to reduce the impact of human factors on the quality of winding.

In summary, the yield rate and production efficiency of water pump brushless motor stator winding can be significantly improved by accurately selecting winding equipment, optimizing the winding process, selecting high-quality materials, strengthening equipment maintenance, improving employee skills and implementing strict quality control measures. At the same time, the active introduction of automation and intelligent technology is also an important direction to improve the quality of winding in the future.

E-Mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]