Standardized management of automated production lines for brushless motor stators and rotors covers multiple key dimensions, including production processes, equipment management, quality management, personnel management, safety management, and continuous improvement. This provides a valuable reference framework for standardization practices in related fields. Based on this information, combined with industry experience and creative expansion, Vacuz offers further insights and supplementary recommendations for key measures:

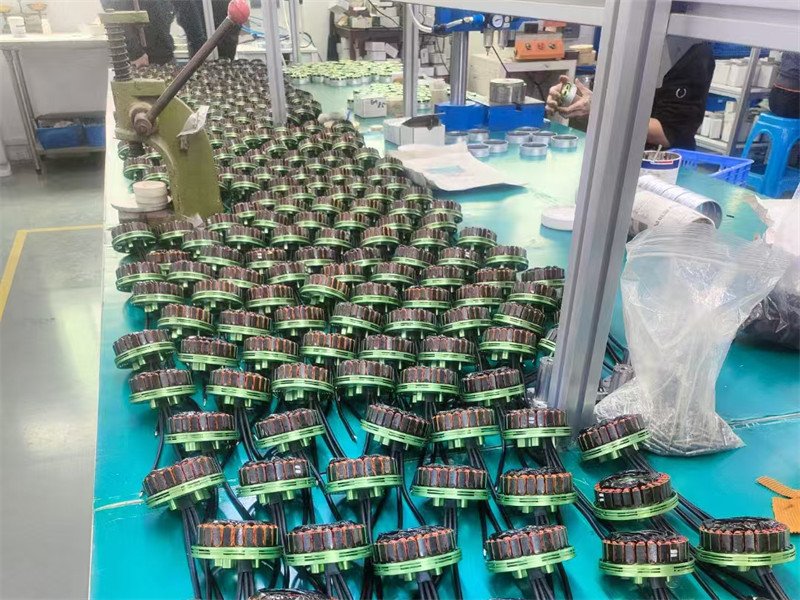

Agriculture Drone Motor Automatic FPV UAV Stator Coil Winding Magnets Insertion Shaft Pressing Machine Production Line

I. Recommendations for Furthering Production Process Standardization

1. Systematization of Process Documents: In addition to existing SOPs and dynamic update mechanisms, it is recommended to introduce digital process simulation. Using virtual simulation technology, the impact of process changes on production efficiency and product quality can be simulated before any changes are made, reducing trial-and-error costs. For example, before adjusting winding tension parameters, simulation can be used to verify the impact of the new parameters on wire breakage rate and slot fill rate.

2. Production Planning and Scheduling Optimization: Further exploration can be made into AI-driven dynamic scheduling. Leveraging machine learning algorithms, production plans can be adjusted in real time based on historical production data, equipment failure predictions, and material supply fluctuations, enabling more flexible response capabilities. For example, if a critical material is predicted to arrive late, the production sequence can be automatically adjusted to prioritize unaffected processes.

3. Innovative Practices in Standardized Equipment Management

Predictive Maintenance and Intelligent Diagnosis: In addition to existing sensors and AI models, it is recommended to build an equipment health management platform. This platform integrates multi-source data (such as vibration, temperature, and current) and utilizes big data analysis and deep learning technologies to achieve real-time assessment of equipment status and accurate fault prediction. Furthermore, AR (augmented reality) technology can provide remote guidance to maintenance personnel, improving maintenance efficiency and accuracy.

Spare Parts Management and Cost Reduction Strategies: Building on the ABC classification method, blockchain technology can be introduced for spare parts traceability management. Leveraging the immutable nature of blockchain, the procurement, usage, and repair history of spare parts can be recorded, ensuring spare part quality while optimizing inventory management and reducing waste. For example, for critical spare parts, the authenticity and remaining life of the parts can be verified through blockchain to avoid the use of counterfeit, substandard, or expired parts.

II. Paths to Improve Quality Management Standardization

1. Quality Gate Setting: It is recommended to increase the use of intelligent quality inspection equipment. For example, machine vision technology can be used to automatically inspect stator core dimensions and enameled wire insulation thickness to improve inspection efficiency and accuracy. At the same time, IoT technology can be used to upload quality inspection data to the quality management system in real time, enabling immediate identification and resolution of quality issues.

2. SPC (Statistical Process Control) Application: This can be combined with big data analysis to conduct deeper analysis of SPC control charts. By analyzing historical control chart data, potential factors affecting process stability, such as ambient temperature fluctuations and raw material batch differences, can be identified. Targeted improvement measures can then be implemented to enhance process capability.

3. Standardized Personnel Management and Optimization of Incentive Mechanisms

Multi-skilled Worker Training System: It is recommended to establish a skills-sharing platform. Employees can be encouraged to share their skills, experiences, and learning experiences on the platform to form an internal knowledge base. Furthermore, through platform data analysis, employee skill gaps and learning needs can be identified, providing a basis for personalized training.

4. Performance Management and Incentive Mechanisms: Gamification elements, such as performance points, leaderboards, and award badges, can be introduced to make performance management more engaging and engaging.

III. Continuous Improvement and Standardization Benchmarking

Industry Benchmarking and Benchmarking: In addition to selecting leading companies within an industry as benchmarks, you can also consider cross-industry benchmarking. Look for companies in other manufacturing sectors that excel in production efficiency, quality control, or cost management. Learn from their success stories to provide new ideas and directions for the continuous improvement of brushless motor stator and rotor automated production lines.

Produktionslinie für Motoren

How can brushless motor stator and rotor automated production lines be standardized? What are some common measures? Vacuz has provided a brief explanation above. We hope this information is helpful!

E-Mail: sales@vacuz.com