The application of garden tools is becoming more and more popular, especially the current brushless garden tools, favored by the majority of friends, as the core part of the garden tools, brushless motor stator coil winding is easy? What winding machine is more appropriate to use? Vacuz give you an introduction to it, I hope it can help you!

Stator für Elektrowerkzeuge

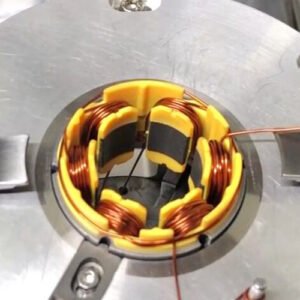

The stator of brushless motor for garden tools is mostly an internal winding product, the general wire diameter is relatively thick, some even up to 1.2mm, such a thick wire, it is difficult to wind by hand, and it is not easy to wind by machine, the key point is that it is easy to injure the wire, and when the coil injures the wire, the motor will have a wide range of problems, which will affect the quality and performance of the motor.

In order to solve the problem of garden tools brushless motor stator winding, you need to use a special internal winding machine equipment, generally can be a two-station or four-station machine, need to pay attention to the following points:

1. Do a good job of positioning between the mold and the needle bar wire nozzle winding, to ensure that when winding, will not hit the needle.

2. After debugging, it should be run several times, and the wound products need to do the pinhole test to ensure that the quality meets the requirements.

3. Winding speed must be slow, too fast and easy to rub the line, injury line.

Automatische Wickelmaschine für Elektrowerkzeuge (zwei Stationen)

Is it easy to wind the stator of brushless motor for garden tools? What winding machine is more suitable? The above has been a simple explanation, Vacuz hope that this little knowledge can help you!

WhatsApp/Wechat: +86 13075286997

E-Mail: sales@vacuz.com