Compared with ring type winding machine, ring type winding machine has the advantages of small magnetic leakage, high efficiency, low noise, light weight, small size, flexible shape design, etc. Z outstanding is light weight (about 50) of the ring type winding machine ~ 70%). But its disadvantages can not be ignored: with ring winding machine does not have the inrush current (harmful to the grid), installation is not as convenient as the ring winding machine, the wire package is exposed, easy to damage in the event of an accidental fall, the cost is slightly higher.

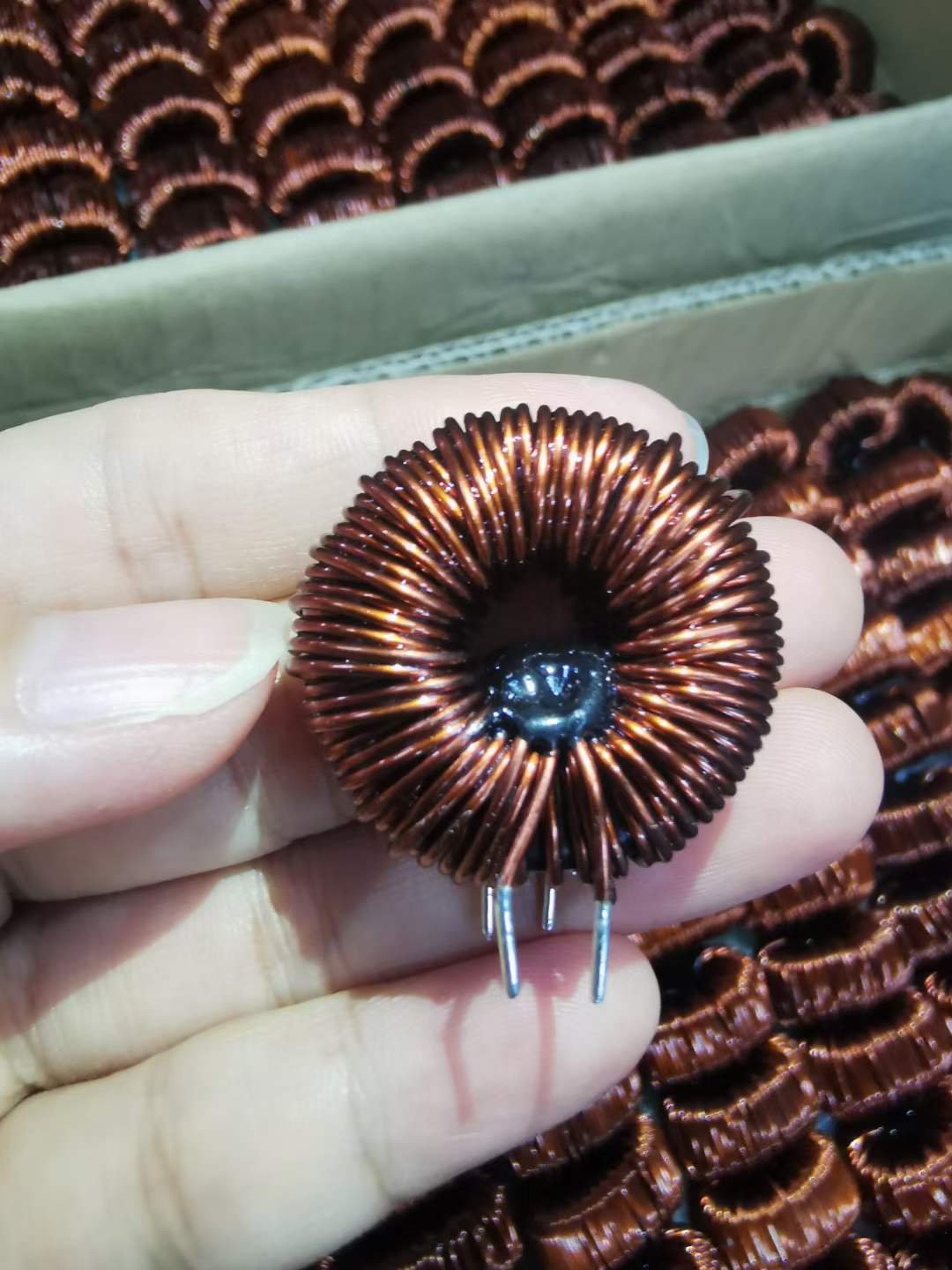

Toroidal-Wickelmaschine

Next, we will introduce the winding process and key points of the wire of the ring type winding machine

1.Winding system

There are two types of winding for production line: semi-automatic winding machine and automatic winding machine. Semi-automatic winding machine can generally be operated by two people, and the paint packing line on the insulation core is one after another. In order to make the winding neat and regular, a plastic film is clamped on the core and pressed into the “inlay slot” before winding. The advantage of semi-automatic winding machine is that manual winding can actively adapt to different wire diameter of the enameled wire. The disadvantage is that the wire is loosely packed and slightly larger.

The working process of the winding machine is: the winding machine has a storage wheel with a cotter pin (also known as a winding shuttle). The cotter pin is removed, the core is covered from the opening, the inner ring of the core is aligned with the circumference of the storage wheel, the cotter pin is closed, the proper amount of wire is stored on the storage wheel, and then the wire on the core is wrapped with storage wire. While the storage wheel is running and winding, the drive mechanism drives the core to rotate slowly so that the paint wire is evenly wound around the core. During the storage wire and winding process, the storage wire wheel always runs at high speed through the inner ring of the iron core. After winding, the remaining wires on the storage wire wheel are removed, the cotter pin is opened and the core is removed, which completes the winding of the wire package.

The diameter of the enameled wire that can be wound by the winding machine is generally within a certain range, because the cell slot size is different.

2. Insulation tying

Core wire insulation – inside and outside both sides with the core wire height of the same strip insulation paper wrapped, both ends filled with the same shape as the end face but slightly larger ring insulation paper. Overlap with the paper tape is required, and then the whole ring is wrapped with narrow insulation tape from end to end. Depending on the insulation grade of the product, the thickness of the above bonding material varies.

The same as the core insulation, but the insulation requirements are higher, the number or thickness of materials increases. v power isolation transformer, overlapping winding insulation winding is not less than 3 layers.

WhatsApp/Wechat: +86 13075286997

E-Mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]