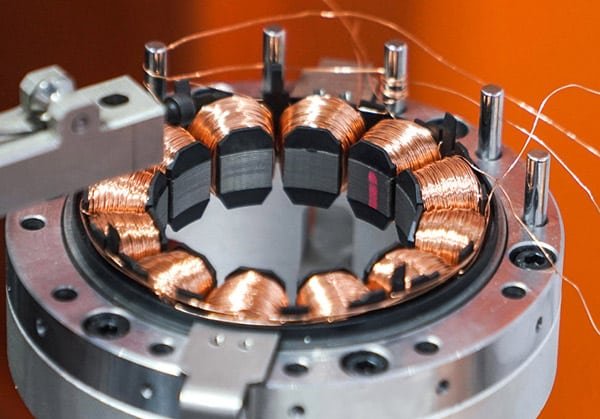

Motor production line is a highly automated production and assembly line, in order to ensure production efficiency and product quality, whether before production, or after production, you need to pay attention to check each component each station to ensure that the production line is running properly. The following points are often noted.

1.Operation data, there are general assembly drawings, parts assembly drawings, parts drawings, material BOM list, etc., must ensure the integrity of the drawings, neatness.

2. Workplace, the placement and assembly of parts must be carried out in the designated workplace, and the workplace must be kept neat, standardized and orderly.

3. Assembly materials, the specified assembly materials must be in place on time during the assembly process.

4. Pre-assembly equipment structure, assembly technology and process requirements. When the assembly work is completed, check the assembly drawing and check whether the parts are missing; check whether the connection between the assembled parts is normal; when testing the motor assembly line, please monitor the starting process carefully; pay attention to test the movement speed, movement stability, rotation of each drive shaft, temperature, vibration and noise, etc.

These are the details that should be paid attention to before and after the assembly of the motor production line. Only by fully grasping these basics can we ensure the normal assembly and stable operation of the motor production line.

WhatsApp/Wechat: +86 13075286997

E-Mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]