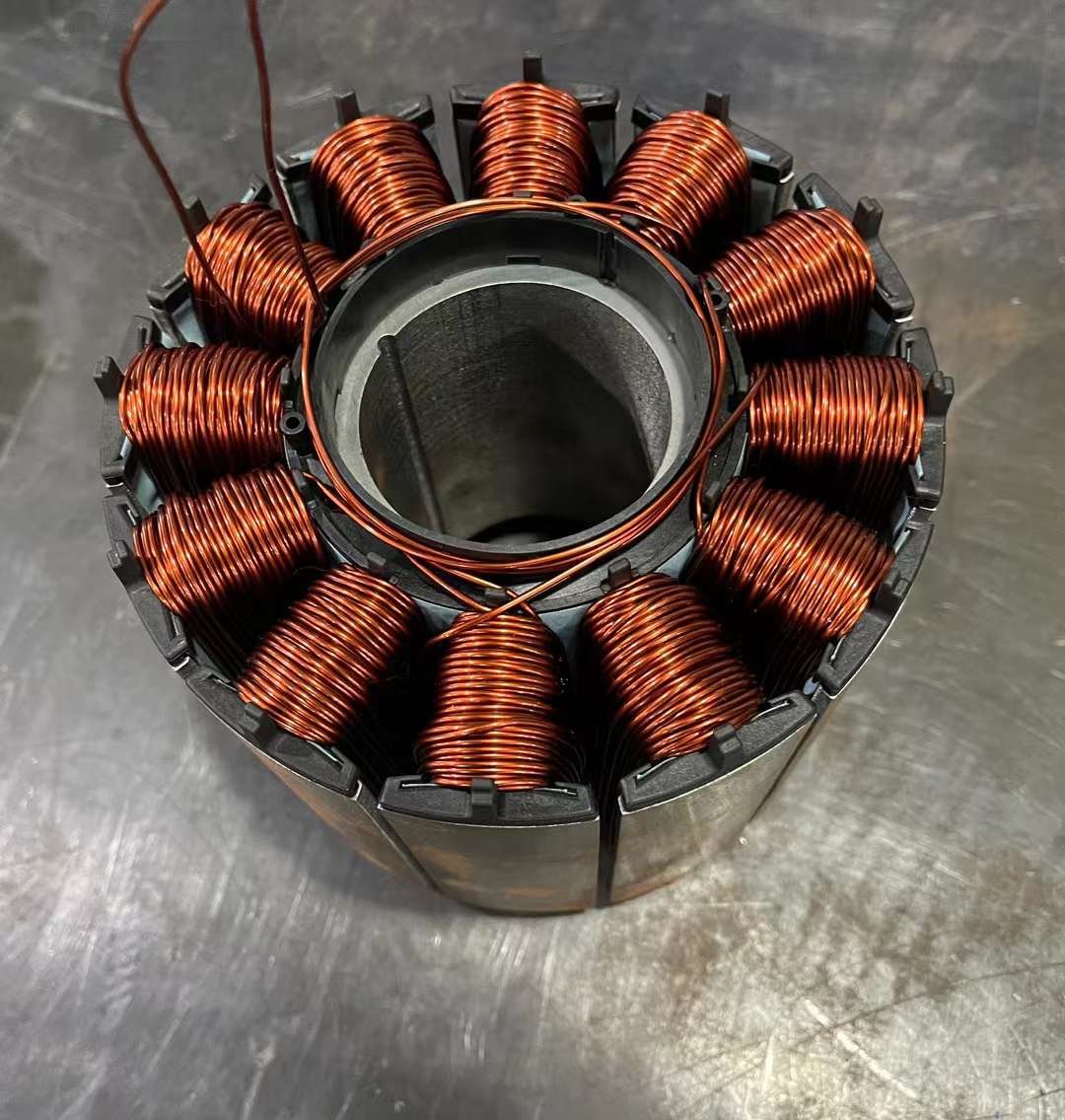

Brushless motor stator winding machine, making the motor stator winding production faster and more efficient, but some friends bought a winding machine, in use for a variety of reasons, resulting in the phenomenon of the crash needle, the wire nozzle was broken, not only delayed production, but also have to replace the new nozzle, the motor stator winding machine hit the needle of how to do? What is the cause? How to avoid it?

1. There are a variety of products, may be each product winding method and program is not the same, in the call if the program does not correspond to, or the product is placed in the wrong, it may lead to the winding machine appeared to hit the needle phenomenon, in order to avoid this situation, should pay attention to the stator molds and programs should be relative to each other, there is no error, and then again and again to confirm.

2. The program is right, the mold installation and positioning is not correct or the screws are not locked stable, may also lead to the center offset phenomenon, should pay attention to install the mold, to ensure that the positioning center and accuracy.

3. Stator and skeleton processing is not standard, rough workmanship, burrs or bumps and so on, resulting in the winding machine running, the wire nozzle was broken, should pay attention to check the stator skeleton, to ensure that the line is accurate.

4. artificial in the stator into the mold above, did not put stable, not put down the card position, resulting in the operation of the phenomenon of hit the needle, which is also relatively common, so be sure to use your hand to press, observe the position of the correct.

5. Human debugging, due to the lack of experience of the debugging staff, in the debugging directly run the program, resulting in the phenomenon of hitting the needle, should be run manually first, step by step, even if the hit the needle, but also can be observed in time to pause, adjust the parameters, and then continue to run manually, until there is no problem.

In order to avoid the above problems, motor stator winding machine before running, should pay attention to check the program and product correspondence, pay attention to check the stator skeleton situation, debugging carefully, to ensure that the over-wire and winding is normal, there is no needles, broken wire, wire injury, stacked wire, skipping and other phenomena.

E-Mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]