For the stable production of rotor assembly line, it really needs comprehensive consideration! This is a complex and detailed process, related to product assembly and quality results, but do not worry, the following Vacuz help you sort out these key factors, so that your production line is more efficient and stable!

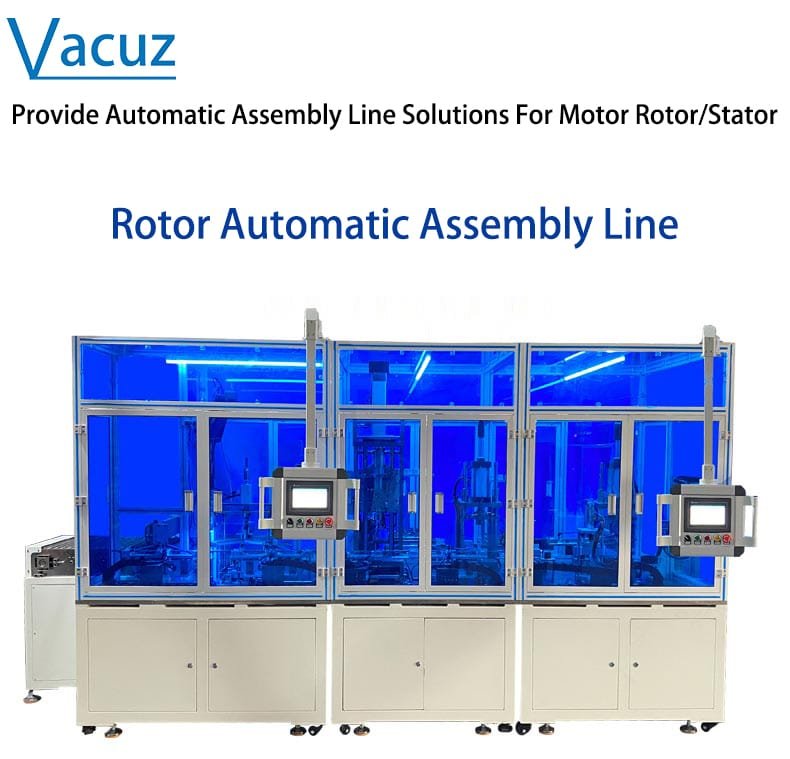

Γραμμή αυτόματης συναρμολόγησης ρότορα

1. Rotor design and raw materials are the foundation of the foundation. Symmetrical structure design can reduce the imbalance, the quality control of raw materials can not be ignored, after all, the material directly affects the performance of the product.

2. Processing technology and equipment is also the key. Improve the precision and stability of the machining process, choose high accuracy and stability of the equipment, these are important factors to ensure product quality.

3. Assembly process control should not be ignored. Detailed assembly process specifications and operating procedures, real-time monitoring functions, these are to ensure the accuracy and reliability of the assembly of the magic weapon.

4. Equipment maintenance and repair is also essential. Regular maintenance program, the establishment of a perfect equipment file, these can make your equipment to maintain a good state, prolong the service life.

5. Environmental control and personnel training are equally important. Maintaining a stable production environment, providing professional training for operators, and developing a perfect quality management system are all key to ensuring orderly production.

Γραμμή αυτόματης συναρμολόγησης ρότορα

6. The introduction of advanced technology and equipment is also an important way to improve production efficiency and quality. Automation, intelligent production equipment, modular production line design, these can make your production line more flexible and efficient.

How can rotor assembly line produce large quantity and stably? What aspects of machine operation should be considered?Vacuz above has made a brief account, I hope these tips can help you!

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com