When checking whether the configuration of the motor stator winding machine meets the requirements, it is really necessary to comprehensively consider a number of aspects, such as the basic performance of the equipment, key components, winding accuracy, safe operation and other details. So how to check whether the motor stator winding machine configuration meets the requirements? What are the common details, Vacuz give you an introduction to it!

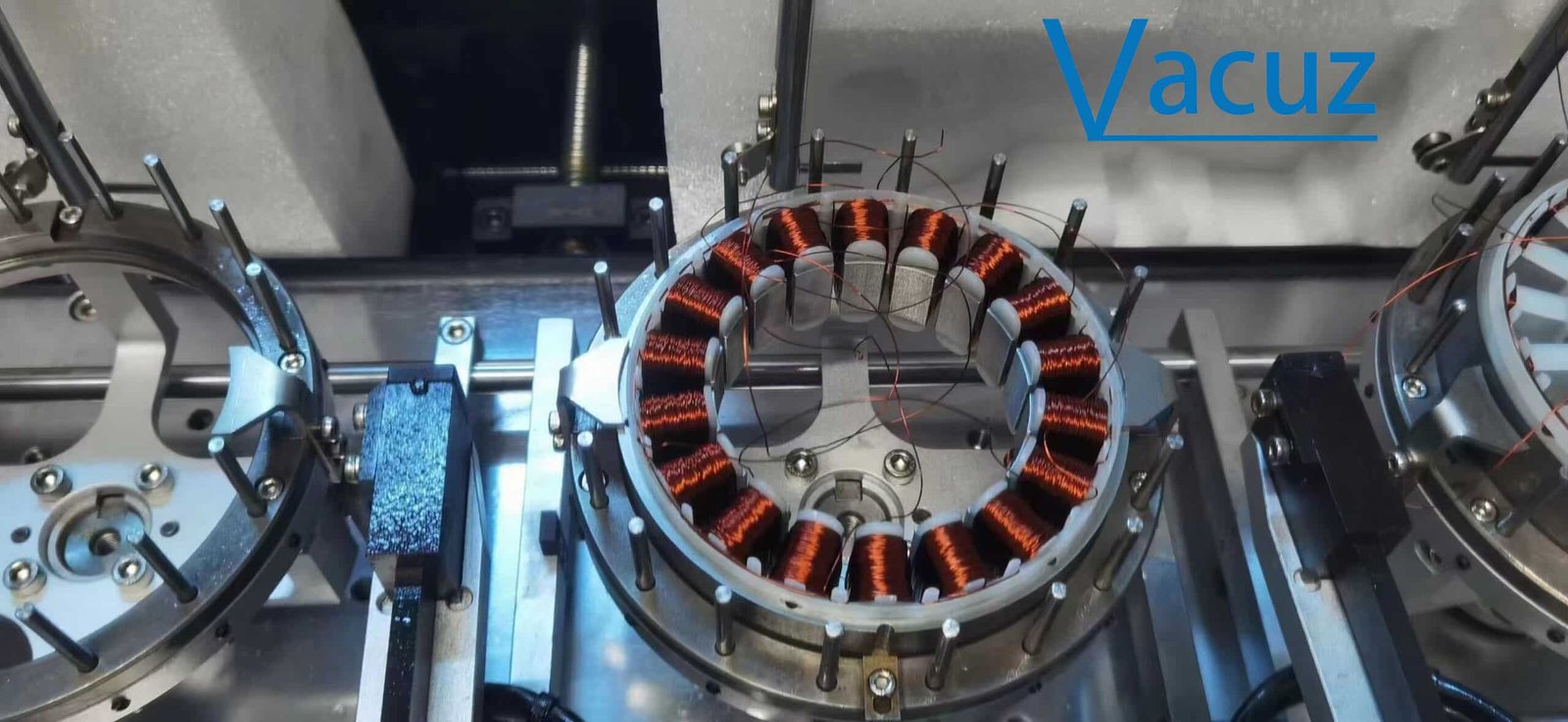

Vacuz 4&6 Stations Electric Toothbrush Motor Automatic BLDC Brushless Inner Hair Dryer Stator Coil Needle Winding Machine Equipment Price

First, the basic performance of the equipment check

1. Winding speed: Ensure that the winding machine has an adjustable winding speed, and can operate stably within the appropriate range. Too fast winding speed may lead to wire breakage, while too slow may affect the overall production efficiency.

2. Tension Control: Verify that the tensioner automatically adjusts the tension range according to the type of wire and wire diameter size to maintain proper tension. Uneven tension may result in uneven coil alignment or wire breakage, affecting winding quality.

3. Power connection: Check whether the power connection is correct to ensure that there is no short-circuit or disconnection phenomenon to ensure the normal operation of the equipment.

Second, the key components check

1. Servo motor and drive system: check whether the brand, model and performance parameters of the servo motor meet the demand of stator winding precision. Choosing the right servo motor system is crucial for improving the winding precision.

2. Guide rail and ball screw: check the precision and wear of the guide rail and ball screw. The accuracy of these components directly affects the positioning accuracy and wire arrangement of the winding machine, so they need to be inspected and maintained regularly.

3. Molds and Fixtures: Ensure that the molds and fixtures are properly fastened to avoid loosening or shaking during winding. At the same time, the precision of the molds and fixtures also need to meet the requirements to reduce the risk of injury to the wire.

C. Winding precision checking

1. Wire arrangement: Select the appropriate wire arrangement according to the size and direction of the stator slot, and verify whether the winding machine can realize the required wire arrangement. Reasonable wire arrangement will help to improve the winding efficiency and coil quality.

2. Notch distance: Adjust the notch distance according to the wire diameter and multi-wire winding situation to ensure smooth winding. Too small a notch distance may lead to scratching or wounding of the wire, affecting the integrity of the coil.

3. Number of turns and slots: Verify that the winding machine can accurately set the number of turns and slots to ensure the accuracy of the winding. This is essential to ensure the quality and performance of stator winding.

IV. Safety Operation Inspection

1. Safety devices: Check whether the winding machine is equipped with the necessary safety devices, such as emergency stop button, protective cover. These devices can protect the operator’s safety in case of emergency.

2. Operating procedures: Understand and comply with the safe operating procedures of the winding machine to ensure that no accidents occur during operation. Regular safety training is also an important way to improve operator safety awareness.

V. Other details check

1. Stability of the equipment: Make sure that the winding machine remains stable during the working process, with no jittering or shaking phenomenon. This helps to improve winding accuracy and coil quality.

2. Worktable: Keep the worktable clean and tidy, no debris interfering with the winding process. This helps to improve working efficiency and winding quality.

3. Maintenance: Understand the maintenance requirements of the winding machine, and carry out regular inspection and maintenance. This helps to prolong the service life of the equipment and maintain its good performance.

Vacuz 4&6 Stations Electric Toothbrush Motor Automatic BLDC Brushless Inner Hair Dryer Stator Coil Needle Winding Machine Equipment Price

In summary, through careful inspection and debugging, you can ensure that the motor stator winding machine in the actual application to play a good performance, I hope these tips can help you!

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com