Many motor manufacturer friends need winding machine equipment, but for the winding machine is not understanding, and do not know exactly how to configure to meet the production needs, then how to choose cost-effective automatic motor stator winding machine? What are the common methods Vacuz to introduce to you!

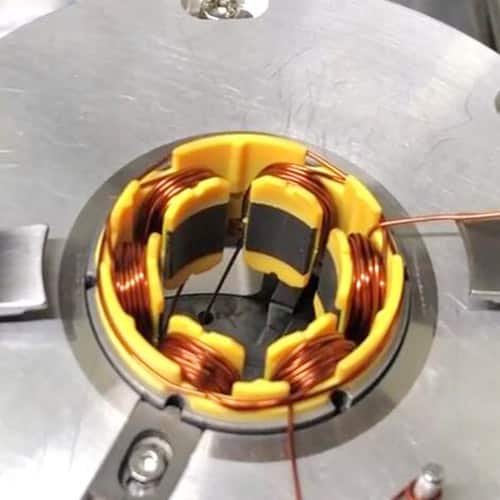

Power Tool Stator

When choosing a fully automatic motor stator winding machine, in order to ensure cost-effective, we need to make a comprehensive consideration from a number of dimensions. The following are detailed methods and recommendations:

First, clear needs and goals

1. Mass production requirements: clear daily production volume, stator model and size, etc., which helps determine the specifications and models of the required equipment.

2. Winding accuracy requirements: According to product requirements, to determine the need for winding accuracy and row effect, to ensure that the selected equipment can meet these requirements.

Second, assess the performance of the equipment

1. Winding speed: Examine the winding speed of the equipment to ensure that it can match or exceed your production requirements.

2. Winding accuracy: Evaluate the winding accuracy of the equipment, including the tightness of the coil, slot fullness, etc., to ensure product quality.

3. Equipment stability: Observe whether the equipment is running smoothly and whether the noise is low to ensure that the equipment can maintain high performance during long operation.

Third, consider the quality of equipment

1. Manufacturer’s reputation: choose a winding machine manufacturer with a good reputation and word of mouth, which usually means higher quality equipment and more reliable after-sales service.

2. Equipment configuration: focus on the equipment control system, motor, guide rail and other key components of the configuration and manufacturing process, which will affect the performance and stability of the equipment.

3. Material selection: high-quality materials can improve the durability and reliability of the equipment, so pay attention to the choice of materials for the main components of the equipment.

Fourth, examine the function of the equipment

1. Degree of automation: choose a high degree of automation of the winding machine, you can greatly reduce labor costs and improve production efficiency. For example, with automatic line, automatic type change, automatic wire cutting and other functions of the equipment.

2. Human-machine interface: friendly human-machine interface and easy operation can reduce the operating difficulty and error rate, improve production efficiency.

V. Consider price factors

1. Cost-effective: based on the evaluation of equipment performance, quality, functionality and other factors, choose a cost-effective winding machine. Do not blindly pursue low-priced or high-priced equipment, according to the actual needs of the selection of suitable equipment.

2. Price Comparison: Compare prices among multiple manufacturers and products to understand market conditions and price trends. At the same time, avoid choosing equipment with too low a price, so as not to sacrifice the quality of equipment and after-sales service.

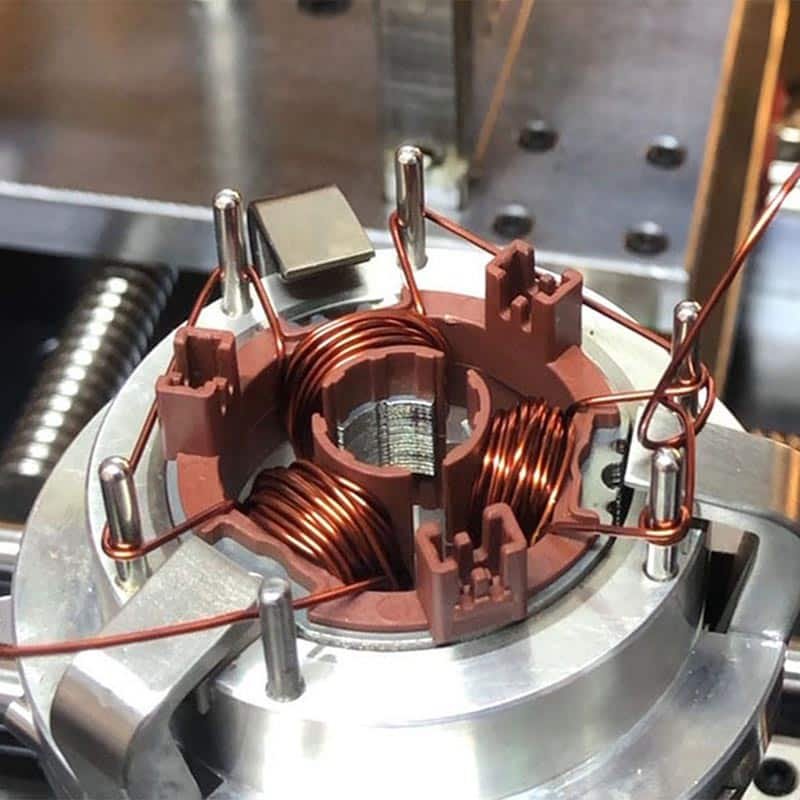

Vacuum Cleaner Stator

How to choose cost-effective automatic motor stator winding machine? What are the common methods?V Above has made a simple explanation, I hope these tips can help you!

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com