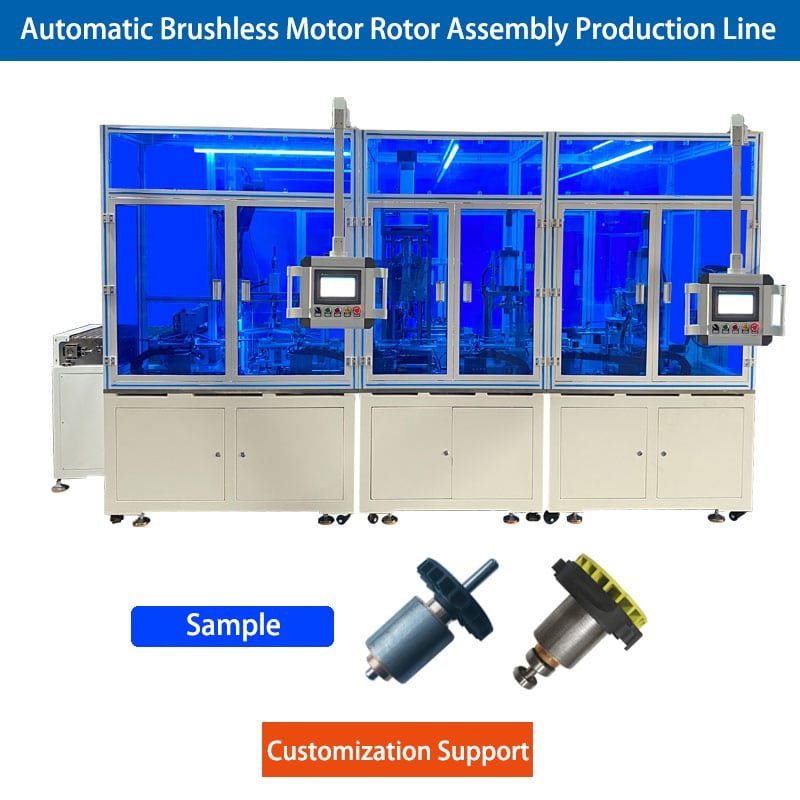

Rotor automatic production line is mainly used for motor rotor assembly of various spare parts, there are a series of production processes, each process is very important, the control of its accuracy is very important, which is to ensure the smooth operation of the premise, so how to control the accuracy of rotor automatic assembly line? How to improve the assembly precision? The following Vacuz and you introduce it!

120 Ton Τιμή εργοστασίου Τιμή βακελίτη Rotor Δίκτυο μετασχηματιστή μετασχηματιστή χύτευσης επαγωγέα Bobbin πηνίο κάνοντας κάθετη πλαστική μηχανή έγχυσης χύτευσης με περιστροφικό πίνακα

First, precision control measures:

1. High-accuracy equipment selection: select stable, high degree of automation assembly equipment, such as high-accuracy robot assembly system, to ensure that equipment accuracy meets or exceeds the production requirements.

2. Precision tooling and fixture design: Design reasonable tooling and fixtures to ensure accurate positioning of the rotor and its components in the assembly, and at the same time, the fixture should have enough rigidity and precision to avoid deformation or error.

3. Sensors and inspection system: introduce high-accuracy sensors to monitor assembly parameters in real time, and utilize visual inspection system for on-line inspection of assembly quality.

4. Strict environmental control: control the temperature, humidity and cleanliness of the production line and other environmental factors to provide workers with a comfortable working environment and reduce the impact of the external environment on assembly accuracy.

Second, measures to improve assembly accuracy:

1. Optimize the assembly process: formulate detailed assembly process and standards, optimize the layout of work stations and equipment configuration through process reengineering and simulation.

2. Implement standardized operation: train workers in standardized operation, improve operation proficiency and accuracy, and ensure that each worker can master assembly skills.

3. Strengthen quality monitoring and feedback: establish a quality inspection database, realize the traceability and sharing of inspection results, summarize and analyze the problems found in the inspection, and continuously optimize the inspection system and process flow.

4. Introduce intelligent technology: Combine sensor data with AI algorithms to realize intelligent judgment and early warning, use big data analysis tools to deeply mine and analyze production data, and formulate scientific production plans and scheduling programs.

5. Continuous improvement and innovation: establish a continuous improvement mechanism, encourage workers and technicians to actively participate in innovation activities, and continuously optimize and improve the problems in the assembly process.

Αυτόματη γραμμή παραγωγής συναρμολόγησης ρότορα κινητήρα χωρίς ψήκτρες

How to control the precision of rotor automatic assembly line? How to improve the precision of assembly Vacuz above that has made a brief account, I hope that this little knowledge can help you!

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com