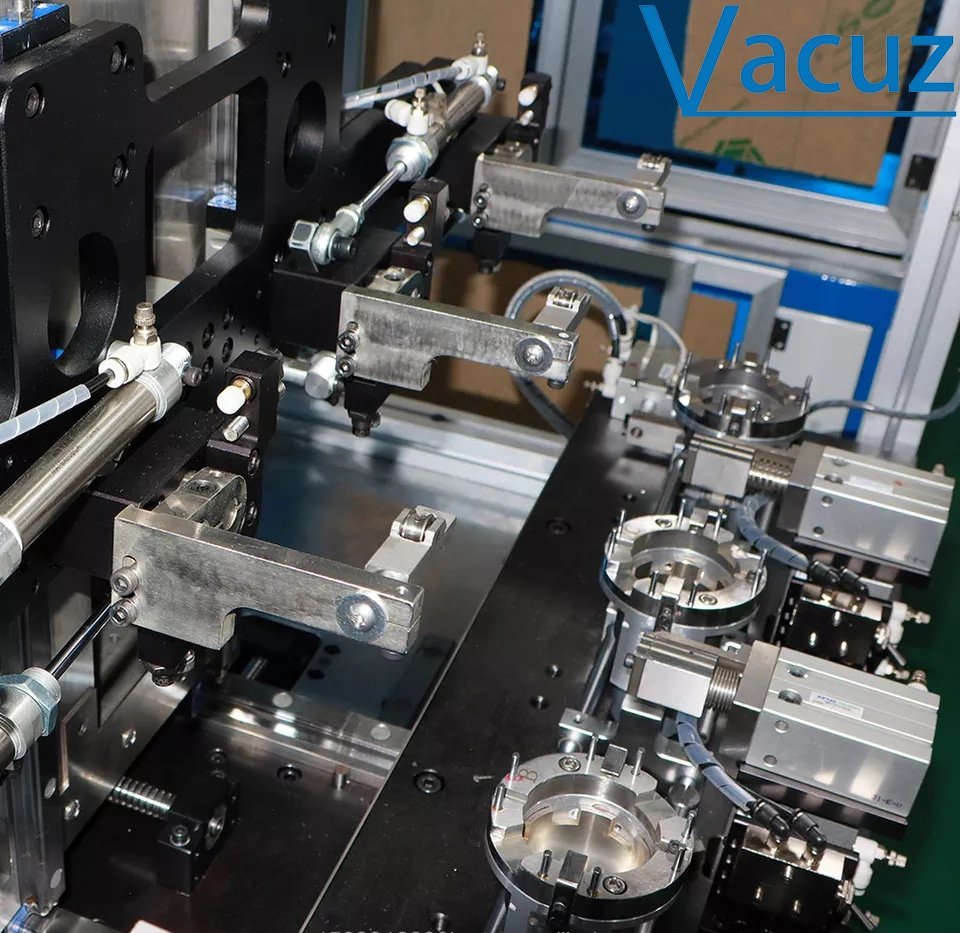

For motor motor stator automatic winding machine, whether it is internal or external winding machine, in order to ensure the high efficiency, accuracy and safety of winding, it is crucial to choose the right nozzle and match it correctly, so how to match the nozzle for the winding machine? What are the requirements for nozzles, Vacuz will give you an introduction!

Υψηλής ταχύτητας τέσσερις άξονες ψύξης ανεμιστήρα κινητήρα αυτόματη BLDC Brushless εσωτερική μηχανή περιέλιξης βελόνων πηνίων στάτη

1. Adaptability is the basis. Nozzle must be closely matched with the type, specification and function of the winding machine, so as to ensure the installation of solid, smooth operation. Next, the precision requirement cannot be ignored, which directly affects the quality of the wound coil. Therefore, when choosing wire nozzles, you must pick the right model according to the precision requirements of winding coils.

2. Material selection is equally important. Nozzle material should be wear-resistant, corrosion-resistant, deformation-resistant and so on, in order to extend the service life and reduce maintenance costs. Carbide, tungsten steel, ruby and other materials commonly found on the market are good choices.

In addition to the above points, the structural design of the nozzle, surface smoothness, strength and hardness, high temperature resistance and ease of maintenance are also factors to be considered. Reasonable structural design can ensure the wire smoothly in and out, reduce friction and resistance; smooth inner surface can reduce the damage to the wire; enough strength and hardness can withstand the winding process of various forces; good high temperature performance can ensure stable operation of the equipment in high temperature environments; and easy to maintain the design to reduce the maintenance cost and difficulty.

When matching nozzles, first of all, according to the type and specifications of the winding machine to choose the appropriate nozzle products. Then, carry out installation and debugging to ensure that the nozzle works well with the winding machine. Later, carry out trial operation before formal production to check whether the winding effect and quality meet the requirements.

In the process of using, also need to pay attention to regular maintenance nozzle, avoid impact and keep clean and dry and other matters. These measures can further ensure the efficiency, accuracy and safety of the winding process.

Motor Stator Transformer Coil Needle Winding Machine Guide Needle

In short, the BLDC motor stator winding machine with nozzle is a comprehensive process, need to consider a number of factors and follow a reasonable matching method and precautions. Only in this way can we ensure the efficiency, accuracy and safety of the winding process.

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com