In the field of motor manufacturing, motor stator winding loading and unloading automatic production line is gradually becoming an important tool to improve production efficiency, reduce costs and ensure product quality. Compared with the traditional manual or semi-automated production methods, automatic production line shows a number of significant advantages, but in the actual application also need to pay attention to some key details, Vacuz to introduce it to you!

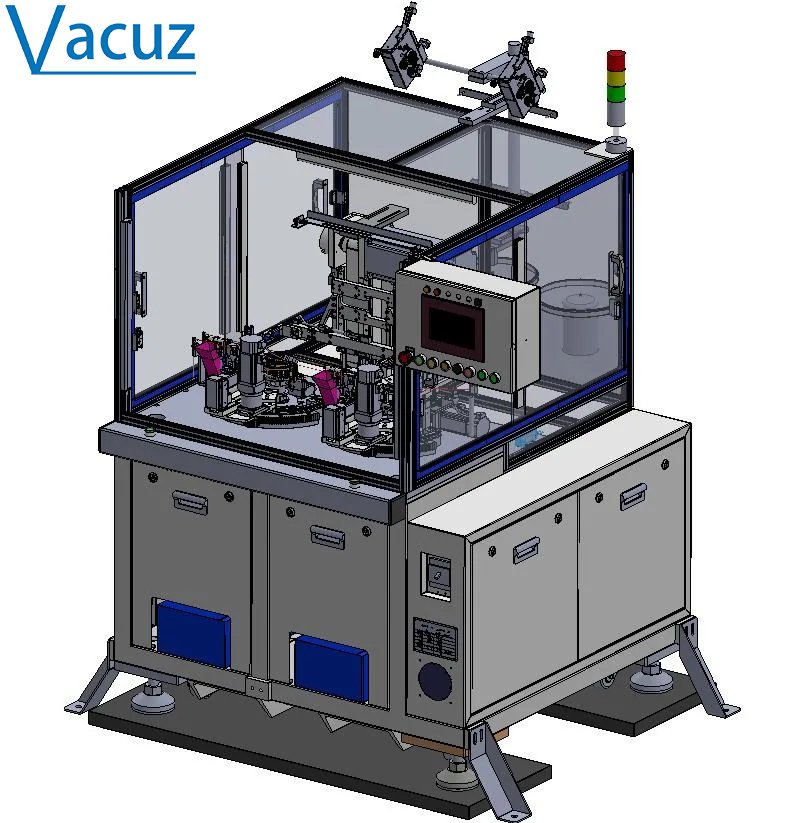

Vacuz R&D Two Stations Automatic Inner BLDC Brushless Motor Stator Coil Needle Winding Machine Equipment

First, the advantages of the motor stator winding and loading and unloading automatic production line

1. Improve production efficiency

The automatic production line significantly improves the production efficiency of motor stator through high-speed, continuous operation. It reduces the time and labor intensity of manual operation, resulting in shorter production cycles and higher output. This efficient production method is of great significance in meeting market demand and enhancing competitiveness.

2. Reduce production costs

The application of automated production line significantly reduces the need for human resources, thus reducing labor costs. At the same time, accurate control reduces the scrap rate, further reducing production costs. In the long run, the maintenance cost of automated equipment is relatively low, and with the increase in production, the cost per unit of product will be further reduced, bringing greater economic benefits for the enterprise.

3. Improve product quality

Automated production lines can accurately control the production process in each step, reducing the interference of human factors. This improves the consistency and quality stability of the product, making the performance of the motor stator more reliable. High-quality products not only enhance the brand image of the company, but also strengthen the trust of customers.

4. Enhanced Flexibility

Automated production lines are usually equipped with programmable control systems that can be quickly adjusted to different production needs. This makes the production line suitable for the production of motor stators of various specifications and models, and improves the flexibility and adaptability of the production line. Enterprises can quickly switch production products according to market demand and improve market competitiveness.

Second, the motor stator winding and loading and unloading automatic production line in the practical application of the details need to pay attention to

1. Equipment selection and configuration

In the purchase of automated production line, enterprises need to choose the appropriate winding machine, loading and unloading devices, conveyor systems and other equipment according to production requirements. Ensure that the performance, accuracy and stability of the equipment to meet the production requirements, is the basis for efficient production.

2. Parameter setting and optimization

Before the operation of the production line, it is necessary to accurately set the parameters of the equipment, such as winding speed, tension, wire diameter and so on. The setting of these parameters will directly affect the quality of the product and production efficiency. Therefore, enterprises need to optimize and adjust the parameters continuously according to the actual situation in the production process to achieve good production results.

3.Quality control and inspection

Setting up quality inspection points in the production line to carry out real-time monitoring and inspection of the key dimensions and performance parameters of the motor stator is an important means to ensure product quality. Enterprises need to be equipped with advanced testing equipment and technology to ensure the stability and reliability of product quality.

4. Equipment maintenance and maintenance

Regular maintenance and repair of automation equipment is to ensure the normal operation of equipment and extend the service life of the key. Enterprises need to establish a perfect equipment maintenance files and maintenance plans, timely detection and treatment of equipment failure and hidden danger, to ensure the stable operation of the production line.

5. Personnel training and management

Although the automated production line reduces manual operation, but the professional skills and quality of operators still have an important impact on production efficiency and product quality. Therefore, the enterprise needs to provide professional training and guidance to the operators, so that they are proficient in automated equipment operating skills and safety standards. At the same time, the establishment of a perfect personnel management system and incentive mechanism to improve the enthusiasm and responsibility of employees.

6. Safety and environmental protection

In the pursuit of efficient production at the same time, enterprises also need to focus on safety and environmental protection issues. Ensure that the production line’s safety protection measures are perfect, to avoid operators from being hurt in the work process. At the same time, comply with environmental regulations and standards, reduce noise, dust and other pollutants in the production process, to achieve green production.

Vacuz R&D Two Stations Automatic Inner BLDC Brushless Motor Stator Coil Needle Winding Machine Equipment

In summary, the motor stator winding loading and unloading automatic production line has significant advantages in improving production efficiency, reducing production costs, improving product quality and enhancing flexibility. But in practice, companies also need to pay attention to equipment selection and configuration, parameter setting and optimization, quality control and testing, equipment maintenance and repair, personnel training and management, as well as safety and environmental protection and other key details. Only comprehensively consider and properly solve these problems, in order to give full play to the advantages of automated production lines, to create greater value for the enterprise.

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com