In the use of needle type internal winding machine, wire nozzle as a key component, its performance directly affects the quality and efficiency of coil winding. Therefore, it is important to choose a reliable nozzle. Vacuz will analyze in detail how to choose the right nozzle for the needle winding machine in terms of suitability, material, precision and durability.

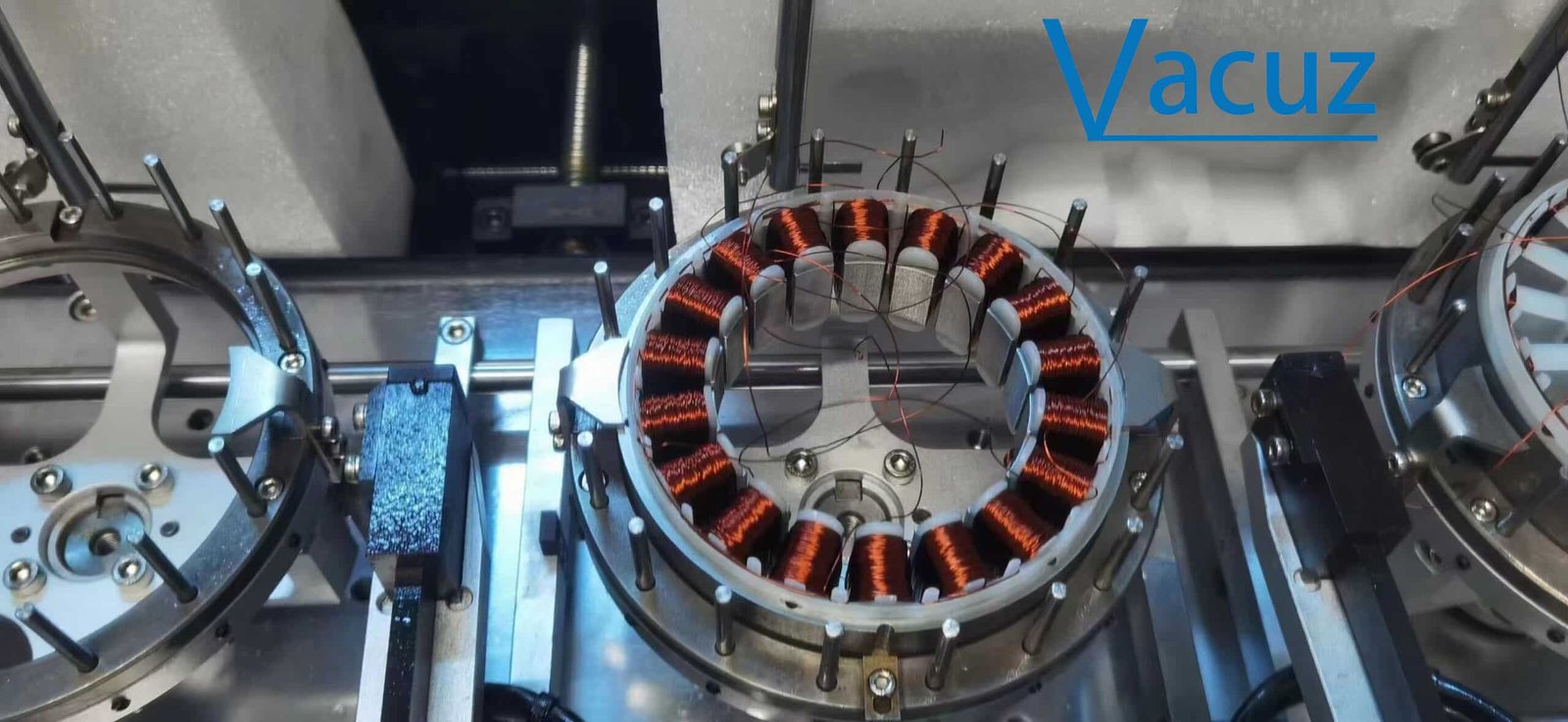

Vacuz 4&6 Stations Electric Toothbrush Motor Automatic BLDC Brushless Inner Hair Dryer Stator Coil Needle Winding Machine Equipment Price

I. Adaptability requirements

1. Matching inner diameter: The inner diameter of the nozzle needs to be matched with the diameter of the wound coil to ensure that the coil is wound smoothly and without obstruction in the winding process, and to ensure the tightness and uniformity of the winding.

2. Matching length: The length of the nozzle should be matched with the length of the wound coil to avoid leakage or short-circuit problems during the winding process.

3. Shape matching: The shape and size of the nozzle should be compatible with the design requirements of the needle winding machine to ensure that the nozzle does not interfere with the stator skeleton, needle bar and other components during the winding process.

Material selection

1. Cemented carbide: high hardness, good abrasion resistance, long service life, suitable for high quality requirements of the wire, large amount of winding and need to run for a long time.

2. Ceramic: smooth surface, not easy to produce burrs, small damage to the wire, but brittle, fragile, suitable for the wire surface quality requirements of the scene is very high.

3. tungsten steel: high hardness, good wear resistance, smooth surface, but easy to rust, need regular cleaning and maintenance, suitable for high quality requirements of the wire and a certain degree of corrosion resistance needs of the scene.

4. Stainless steel: inexpensive, easy to process, but the hardness is low, easy to wear, short service life, applicable to the general requirements of the quality of the wire and limited cost budget scenarios.

Third, precision and durability

1. Surface finish: the surface of the nozzle should be smooth and flawless to reduce friction and damage to the wire, while reflecting the manufacturer’s processing accuracy and quality control level.

2.R angle roughness: The roughness of the R angle on both sides of the wire nozzle is a key factor affecting the quality of the wire, the lower the roughness, the less damage to the wire.

3. Bore roughness: The roughness of the nozzle’s bore needs to be kept at a low level to ensure the uniformity and tightness of the winding.

4. Durability: choose a durable nozzle can reduce the frequency of replacement and maintenance costs, durability mainly depends on the material, processing precision and use of environmental factors.

Other considerations

1. Brand and manufacturer: choose a well-known brand and manufacturer of the nozzle, usually has a more complete production process and quality control system, quality is more secure.

2. After-sales service: when purchasing nozzles, should pay attention to the manufacturer to provide after-sales service, including technical support, maintenance services, etc., to ensure that the nozzle in the use of the process of timely and effective maintenance and support.

3. Regular maintenance and repair: no matter what kind of material and brand of nozzle, you need to carry out regular maintenance and repair, in order to extend its service life and maintain good working condition.

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

To summarize, choosing a reliable nozzle for needle winding machines requires comprehensive consideration of fit, material, precision and durability. By carefully comparing the products of different brands and manufacturers, and selecting them in accordance with the actual needs and use environment, you can ensure that you choose the right nozzle, thus improving the quality and efficiency of coil winding.

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com