Many friends are looking for automatic brushless motor stator winding machine, but for this line is not very understanding, do not know where the manufacturers are mainly, as well as for the machine is not very knowledgeable, so the winding machine manufacturers are mainly concentrated in where? How to distinguish the quality of the winding machine good or bad, Vacuz give you an introduction to it!

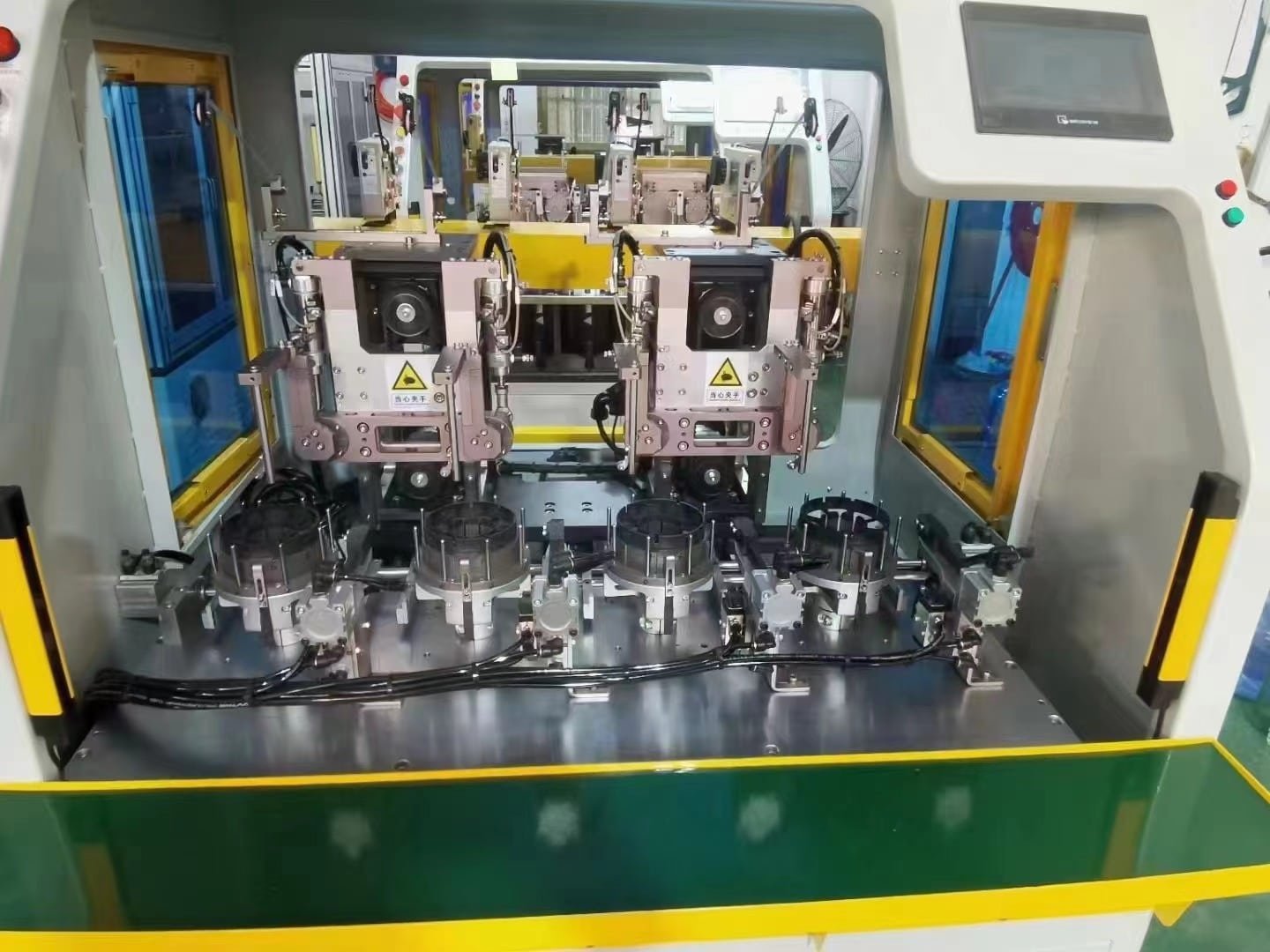

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

Automatic brushless motor stator winding machine manufacturers distribution and quality identification:

Automatic brushless motor stator winding machine, as the key equipment in the motor manufacturing process, the location of its manufacturers and the quality of the equipment are the focus of users.

First, the main distribution of automatic brushless motor stator winding machine manufacturers

Automatic brushless motor stator winding machine manufacturers, mainly concentrated in the Pearl River Delta and Yangtze River Delta, especially in Guangdong, Zhejiang, Jiangsu provinces. These regions have a solid industrial base, a complete supply chain and convenient logistics network for the production of winding machines provide unique conditions.

Second, how to distinguish between good and bad quality of the winding machine

Choosing a high-quality automatic brushless motor stator winding machine is crucial for improving production efficiency and ensuring product quality. Here are a few key points to identify the quality of the winding machine:

1. Examine the brand and manufacturer: give priority to well-known brands and manufacturers with a long history and good reputation, they usually have more mature technology and better after-sales service.

2. Analyze the performance of the equipment: focus on the winding speed, accuracy and stability of the winding machine and other performance indicators. High-performance winding machine will significantly improve production efficiency and product quality.

3. Check the material and process: high-quality materials and good workmanship is the equipment durability and low failure rate guarantee.

4. Understand the after-sales service: equipment warranty, maintenance response time and technical support and other after-sales service is equally important, they can ensure the continuous and stable operation of the equipment.

5. Reference to user evaluation: other users of the use of feedback is the evaluation of equipment performance and reliability of the intuitive basis.

6. Field visit and test machine: If conditions allow, personally visit the manufacturer and test machine, can more accurately assess the actual performance and quality of the equipment.

7. Weigh the price and cost-effective: under the premise of ensuring quality, compare the price of different brands and models, choose the cost-effective and high-quality winding machine equipment.

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

Where are the automatic brushless motor stator winding machine manufacturers mainly concentrated? How to distinguish between good and bad quality winding machine Vacuz above has made a simple explanation, I hope this knowledge can help you!

Ηλεκτρονικό ταχυδρομείο: sales@vacuz.com