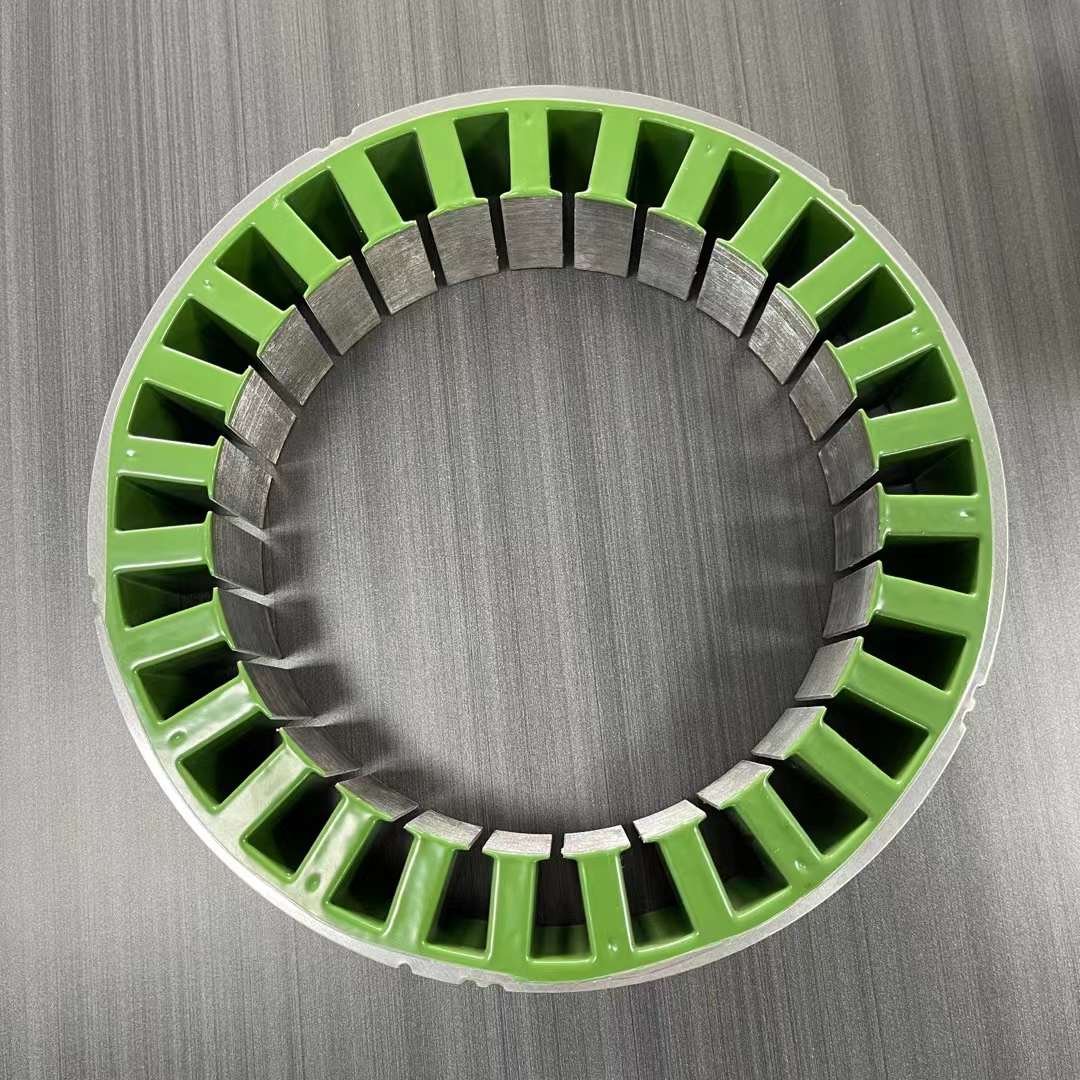

Needle type internal winding machine is more widely used, common brushless motor inner stator need to use the internal winding machine equipment, then how to optimize the winding production process of needle type internal winding machine? What details and knowledge need to pay attention to Vacuz give you an introduction to it!

Vacuz Big BLDC Estator Automático Sin Escobillas Motor Interior Bobina Aguja Bobinadora Entrega

In the optimization of the winding production process of the needle type internal winding machine, it is indeed necessary to consider from a number of aspects, the following is a detailed explanation of the common optimization methods and additions:

I. Optimize the winding speed

1. Adjust the speed according to the wire diameter

a. Fine wire: when the wire diameter is 0.1-0.3mm, the winding speed can indeed be set within the range of 500-800R.P.M. The winding speed can be adjusted according to the wire diameter and the wire diameter. In order to avoid wire breakage, it needs to be fine-tuned according to the material and toughness of the wire as well as the specific requirements of the product.

b. Coarse wire: when the wire diameter is 0.7-1.2mm, the winding speed should be controlled at 150-300R.P.M. In addition to the wire diameter, the hardness, tensile resistance and other characteristics of the wire need to be taken into account to ensure that the winding process is stable.

c. Multi-wire parallel winding: For products with multi-stranded wires, the winding speed needs to be adjusted more carefully. Due to the friction and interference between multiple wires, it may increase the risk of wire breakage. Therefore, it is recommended to reduce the winding speed appropriately under the premise of ensuring the quality of winding.

II. Optimize the winding method and structure design

1. Simplify the winding method

a. Reduce unnecessary actions and waiting time by optimizing the steps of winding, crossing, starting and stopping to improve the winding efficiency.

b. Introduce automation and intelligent technology, such as automatic wire changing, automatic detection and other functions, to further reduce the difficulty of operation and improve production efficiency.

2. Improve machine accuracy

a. Choose high accuracy transmission parts and control system to ensure the accuracy and consistency of each action in the winding process.

b. Regularly maintain and repair the machine to keep its good working condition and precision.

Third, mold processing

1. Improve the precision of mold

a. The design and manufacture of the mold should meet the requirements of the product, and the precision should reach a certain standard. Improve the precision and durability of the mold by optimizing the mold structure and manufacturing process.

b. Regularly check and calibrate the mold to ensure that its accuracy is always maintained within a certain range.

2. Polishing and sanding

a. Polishing and sanding of the molds should be carried out carefully to ensure that the surface is smooth and burr-free to minimize damage to the wire.

b. Use appropriate polishing and sanding tools to avoid excessive wear or damage to the mold.

Fourth, the configuration and spare parts selection

1. Determine the winding program according to the sample

a. According to the specific requirements of the product and the characteristics of the sample, select the appropriate configuration of servo motors, screws, guide rails, tensioners, wire nozzles, needle bars and so on.

b. Ensure that the selected configuration can meet the precision, speed and quality requirements of the product.

2. Avoid substandard products

a. Select reliable quality and stable performance of spare parts, to avoid the use of poor-quality products to affect the performance of the machine and product quality.

b. Regularly check and replace the spare parts to ensure that they are in good working condition.

V. After-sales service

1. Rapid response

a. The installers need to have professional technical knowledge and rich practical experience, and be able to quickly rendezvous with the operator to get started and solve basic problems.

b.Vacuz set up a specialized after-sales service team to provide 24-hour online service support and technical guidance.

2. Timely maintenance

a. For problems or failures in the process of use, the after-sales service team needs to respond quickly and solve the problem on the doorstep in a timely manner.

b. Provide regular maintenance and repair services to ensure that the machine is always in good working condition.

VI. Other Precautions

1. Injury to the line

For thick wire products, special attention needs to be paid to the problem of wire injury. The risk of wire injury can be reduced by optimizing the winding method, adjusting the winding speed and using suitable molds.

2. Product quality

While pursuing production efficiency, the importance of product quality should not be ignored. We need to establish a perfect quality inspection system and control process to ensure that each product meets the quality requirements.

Servomotor automático sin escobillas de bobina interna de estator tipo máquina de bobinado de aguja

How to optimize the winding production process of needle internal winding machine? What details and knowledge need to pay attention to? Vacuz has done a simple explanation above, I hope these tips and details can help you!

Correo electrónico: sales@vacuz.com