By what means the automatic winding machine is speed regulated!

Some pals will think that deep punching dies are manufactured, I don’t think so. The correct technique is copper tube ——- automotive machining cutting ——- die stamping ——- Dunn stamping forming.

1. Purchase the copper tube and machine it to the proper length using an automatic lathe. The exact length needs to be determined by proofing.

2. Die exhaust grooves. The die is very weak because the outer diameter of the product is only 8.5 due to the thin grooves on all sides. Normally, there are three punching methods for the four oval holes.

a: One punching, which requires four consecutive holes. Since the four holes are evenly spaced, it is necessary to fix the rotation by positioning the holes before punching, which is very inefficient. Because of the large product tolerances, some factories run very fast and rely on workers to control the angles based on their own feel. They do not need to be positioned. Despite the very high speed, the price is higher. Plug die construction, where the upper die is the punch and the lower die is made into a 7 shape, the mandrel can be fixed to the whole die or even to the die base.

Improvement: Make a tissue to clamp the copper sleeve and push the sleeve to rotate automatically by the up and down, left and right fitness movement of the high speed punching machine.

Bobinadora automática

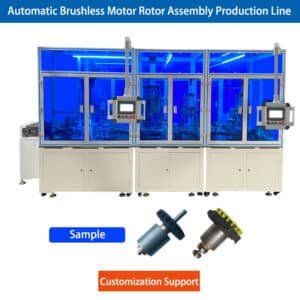

Línea de producción automática de ensamblaje de rotores de motores sin escobillas

b. Second method: punch long holes up and down, two at a time, and then punch 90 degrees before punching. Mold structure: can slide up and down, also can slide left and right.

C. Three ways: place the goods vertically, place the rails around, and flush the four slots. When I was working in Longgang, Shenzhen, this method really worked. I have designed a whole set of solutions. Key: The wound gap should be good to avoid burrs or picking up the goods. The fall of the waste should be smooth and the core should explode. The surrounding guide slides can be driven by the lower die wedge drive or can be used with 4 small cylinder drives. The tool previously designed for small weaving machines is fixed to the frame and the large cylinder is mounted in the center of the bottom of the frame. The cylinders move up and down and the four slides are driven simultaneously by a lever mechanism.

3. Duncheng processing. A flat plate is fixed to the upper die by a small bench press, a tungsten sleeve is mounted on the lower die, and a copper sleeve is placed in the tungsten sleeve. The r-angle in the sleeve is pushed out relative to the r-angle in the copper sleeve.

WhatsApp/Wechat: +86 13075286997

Correo electrónico: sales@vacuz.com