Rotor and stator is an important part of the motor, the traditional assembly method can not meet the actual demand, the quality can not be guaranteed, so how to automate the rotor magnet assembly and stator winding? What are the common methods, Vacuz give you an introduction!

Automation of rotor magnet assembly:

First, the automatic separation and feeding of magnets:

1. Equipment application: the introduction of the magnet steel automatic separation and loading device, like an intelligent sorter on the production line, can accurately and precisely separate the magnets from the stack one by one, and accurately placed on the assembly line, laying a solid foundation for the subsequent processes.

2. Technical points: The core of the device lies in its high accuracy and stability, ensuring that the magnets are protected from damage during the separation process, while realizing efficient and accurate transmission.

II. Polarity checking and magnetic flux matching:

1. Application of equipment: Equipped with polarity checking device and magnetic flux measuring equipment, just like a quality inspection expert, the polarity and magnetic flux of magnets are meticulously checked and measured.

2. Technical points: Through advanced programming control technology, the equipment can automatically complete the polarity identification and magnetic flux measurement of the magnets and intelligently match them according to the measurement results to ensure that each pole of the assembled motor has balanced magnetic flux and excellent performance.

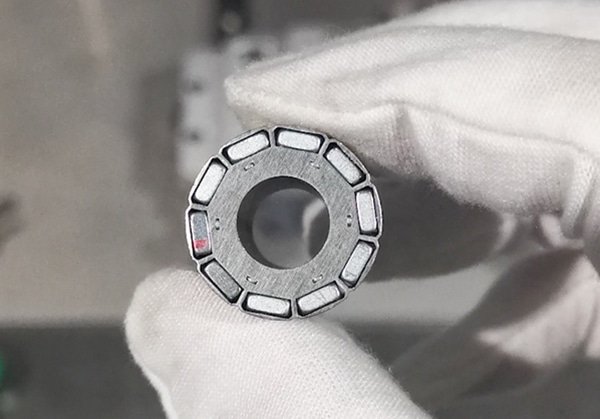

Third, automatic assembly:

1. Application of equipment: Precision robotic arm and sensor technology shine in this section, they work together to achieve high accuracy assembly of magnets.

2. Technical points: The accurate grasping and placing ability of the robotic arm, combined with the real-time monitoring function of the sensors, ensures that the magnets can be accurately and precisely loaded into the rotor slots, and at the same time, meets the stringent assembly accuracy requirements. In addition, post-assembly quality inspection is also an indispensable part, which ensures that the assembly quality is foolproof.

Automation of stator winding:

I. Automatic winding machine:

1. Equipment application: automatic winding machine as the core equipment for stator winding, its customized design meets the needs of different stator shapes, sizes and winding methods.

2.Working Principle: Through the programmable control system, the automatic winding machine realizes the precise control of the functions such as forward and reverse rotation, starting and stopping, speed change and automatic line winding. Flying fork winding machine as one of the best, with its unique flying fork design and control system, realizes efficient and accurate winding of enameled wire.

Second, wire arranging device and mold:

1. Application of equipment: Precise wire arrangement device and customized mould together constitute an accurate guiding system for stator winding.

2. Technical Points: The high precision and stability of the wire arrangement device ensures the quality of the wire arrangement during the winding process; while the customized molds are accurately matched according to the shape and size of the stator slots to ensure the accuracy of the winding position.

Second, tension control:

Technical points: Tensioner plays a key role in this link, it ensures stable and moderate wire tension during the winding process by accurately controlling the tension of the enameled wire. This not only avoids the problem of not winding the wire tightly due to too loose wire, but also prevents the phenomenon of broken or injured wire that may be caused by too much tension.

Third, quality inspection:

Technical points: after the completion of winding, the quality inspection of the stator is an important part of ensuring product quality. Through the combination of visual inspection and instrumental measurement, the neatness of the winding, the damage of the enameled wire and the accuracy of the number of turns of the winding are comprehensively inspected to ensure that each motor can achieve superior winding quality.

How to automate rotor magnet assembly and stator winding? What are the methods?Vacuz above has done a simple explanation, I hope these tips can help you!

Correo electrónico: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]