Automatic winding machine tutorial_Automatic winding machine debugging video_One of the processes in the inspection of our automatic winding machine is to perform an over-speed experiment on the automatic winding machine, the method of this experiment is to increase the speed of our automatic winding machine to more than 120% of the rated speed. We do this to check the installation quality of the winding machine, to test the mechanical strength of the rotor parts to withstand the centrifugal force and the mechanical strength of the bearings at over speed.

Automatic winding machine over-speed operation, but also to increase the frequency of the supply voltage of the tested winding machine, or use the auxiliary winding machine to drag the tested winding machine to increase its speed. In addition, to increase the power supply of the automatic winding machine, the voltage frequency method, at present are used silicon controlled frequency conversion device – frequency power supply. And the method to increase the speed is to reduce the excitation current or increase the armature end voltage.

However, the increase in end voltage is less than 130% of the rated voltage, and reducing the excitation current will result in a smooth increase in speed. For all automatic winding machines are required, it can support 2m minutes without deformation at increased speed, so that the automatic winding machine is qualified.

Automatic winding machine manufacturer

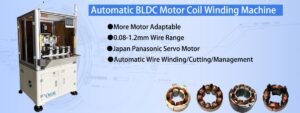

The automatic winding machine is divided into two parts: winding and line up, so the transmission part of the automatic winding machine is also independent of the two parts.

The transmission of the winding part is to transfer the rotation of the motor to the chuck, so that the chuck rotates according to the established speed of the computerized automatic winding machine research and development to complete the winding action. The drive of the winding part is to convert the rotation of the stepper motor into a flat motion and to arrange the wire according to the technical requirements. The load and precision of the two parts are different. The winding part requires high rotational speed and large load, but not high precision, while the lining part has low rotational speed and light load, but high precision. Therefore, in the whole structure design, the good or bad design of the transmission system is related to the accuracy, efficiency and reliability of the whole system.

Flat belt drive relies on the inner surface of the belt ring and the outer surface of the pulley to produce friction. Commonly used flat belts are canvas core flat belts, leather flat belts, woven flat belts and composite flat belts. Generally connected with a joint into a ring, so the transmission is not smooth enough. Because the flat belt is soft and can be twisted, in the small power transmission according to the relative position of the shaft and rotation relationship can be divided into three main transmission forms: open drive – two parallel shafts, the same steering, is the common form; cross drive – two parallel shafts, opposite steering, used to change the direction of rotation; semi-cross drive – The two shafts are staggered, the staggering angle is usually ninety degrees, used to transmit the rotation between the two staggered shafts in space, with a semi-staggered state, only suitable for one-way transmission.

WhatsApp/Wechat: +86 13075286997

Correo electrónico: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]