The automation functions of brushless stator winding machines are mainly reflected in mechanical structure linkage, control system integration, software algorithm optimization, multi-station parallel operation, and automated loading and unloading. Human-centered design focuses on a user-friendly interface, diverse interaction methods, safety protection mechanisms, ease of maintenance, and personalized customization. Below, Vacuz will give you a brief introduction!

I. Specific Manifestations of Automation Functions

1. Mechanical Structure Automation:

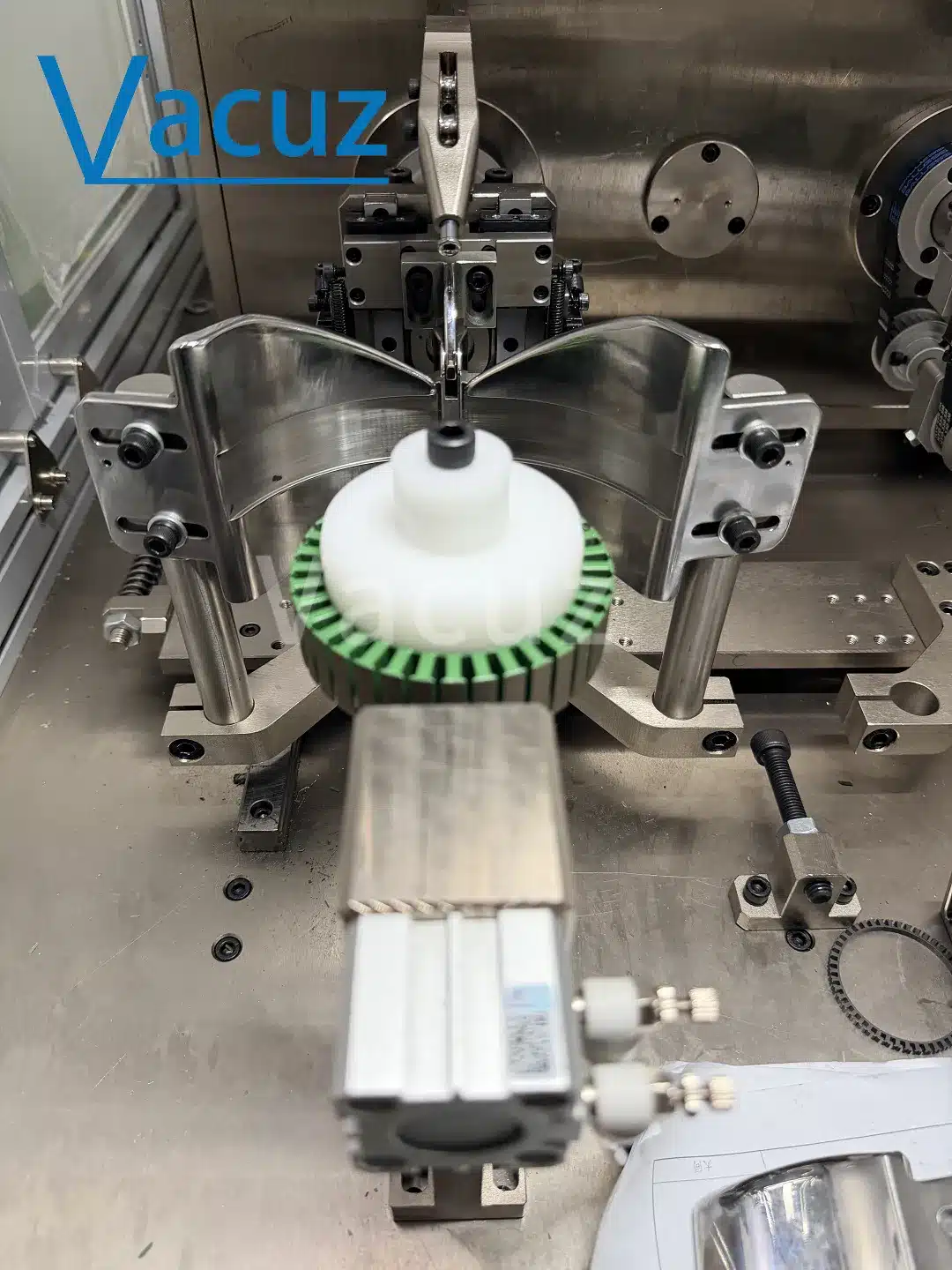

Multi-axis linkage control technology: Brushless stator winding machines adopt multi-axis linkage control technology. Servo motors drive the X, Y, and Z axes to work collaboratively, coordinating with the rotating spindle to accurately draw the winding trajectory in three-dimensional space. For example, in a needle-type internal winding machine, a servo motor drives the needle bar to move at high speed, while the die moves left and right, accurately winding the enameled wire into the stator slot.

Modular fixture design: The modular fixture design allows for quick equipment changeover to adapt to different stator models, greatly shortening changeover time and improving production efficiency.

2. Intelligent Control System:

PLC and Servo Drive Integration: The integration of PLC and servo drive allows for real-time adjustment of winding parameters such as speed, tension, and number of turns, ensuring consistency and stability in the winding process.

Human-Machine Interface (HMI): The introduction of a HMI simplifies operation, supporting parameter setting, program calling, fault diagnosis, and other functions, providing convenience for operators.

3. Software Algorithm Optimization:

Intelligent Wire Laying Algorithm: The built-in intelligent wire laying algorithm automatically generates the winding path based on parameters such as the number of stator slots and wire diameter, effectively avoiding problems such as skipped wires and wire breaks.

Closed-Loop Tension Control System: The application of a closed-loop tension control system monitors and adjusts the tension of the enameled wire in real time, ensuring the tightness of the winding and the integrity of the wire.

4. Multi-Station Parallel Operation:

Supports simultaneous operation of dual or multiple stations. For example, a dual-station flying fork winding machine can process two stators simultaneously, further shortening the production cycle and increasing capacity.

5. Automated Loading and Unloading:

Advanced robotic arms or conveyor belt technology enable automated loading and unloading of stators on the production line, significantly reducing manual intervention and improving production continuity and stability.

II. Specific Manifestations of Human-Centered Design

1. User-Friendly Interface:

Intuitive Graphical Interface: An intuitive graphical interface design, combined with icons and text descriptions, reduces operational difficulty, allowing operators to quickly learn how to use the equipment.

Operation Guides and Video Tutorials: Detailed operation guides and video tutorials are provided to help operators quickly master the equipment’s operation.

2. Diverse Interaction Methods:

Voice Interaction Function: In addition to the touchscreen, voice interaction functionality is added, supporting voice command input and feedback, improving operational convenience.

Personalized Settings Options: Personalized operation interface settings options are provided for different operators to meet the needs of various users.

3. Safety Protection Mechanism:

Safety Protection Devices: The equipment design takes operator safety into account, such as the inclusion of safety protection devices and emergency stop buttons to ensure rapid shutdown in emergency situations.

4. Mistake-proof and error-proof design: For components prone to misassembly, omission, or reverse assembly, process measures are employed to ensure that these errors do not occur. Every part of manual assembly requires inspection and correction, with corresponding reminders provided.

5. Ease of maintenance:

Modular design: The mechanical structure is designed for easy disassembly and assembly, facilitating maintenance and upkeep. Modular design also allows for independent upgrades or replacements of different functional modules, improving the equipment’s flexibility and scalability.

Maintenance manual and repair videos: Detailed maintenance manuals and repair video tutorials are provided to help users quickly resolve common problems.

6. Personalized customization:

Personalized customization is available based on specific usage scenarios and needs to meet customers’ special requirements. For example, non-standard customization services can be provided for the development of special winding processes.

How is the automation function of the brushless stator winding machine reflected? How can it be designed to be more user-friendly? Vacuz has provided a simple explanation above, and we hope this information is helpful!