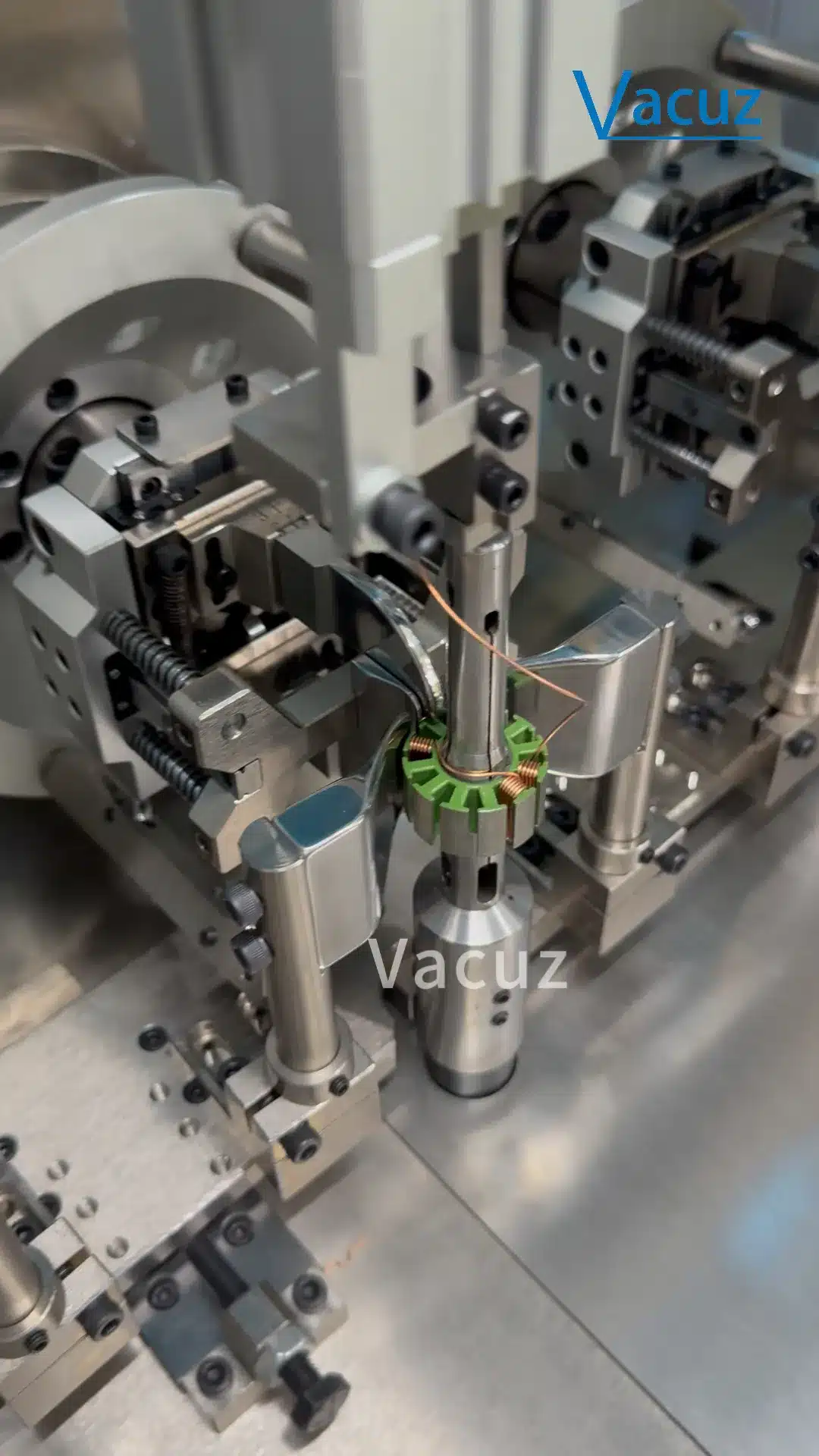

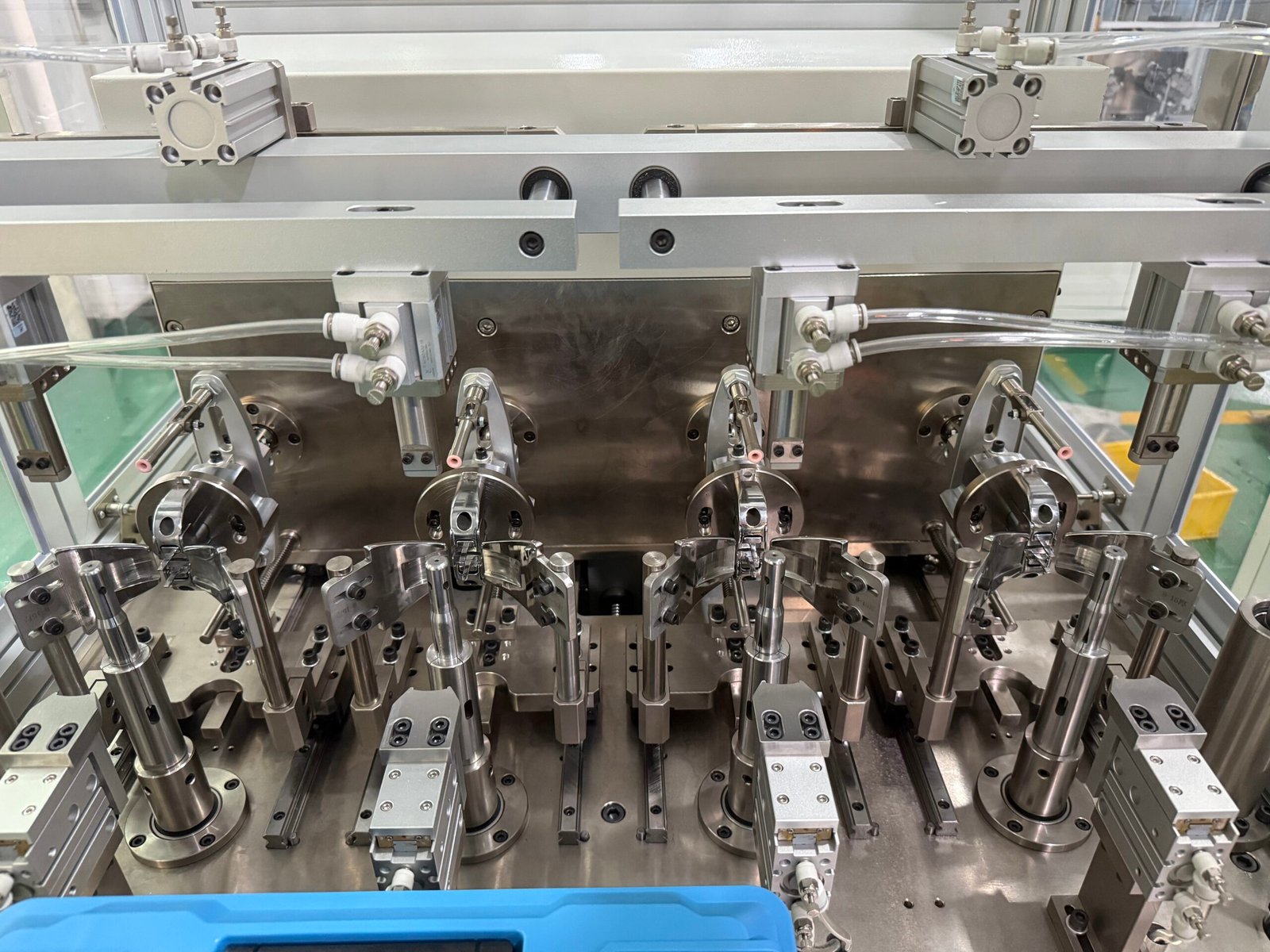

High-speed stator winding machines have relatively high requirements for output. They generally adopt a multi-station design, which can greatly improve production efficiency. However, with the increase in the number of stations and high-speed winding requirements, machine positioning and consistency control are very important. So how to control the consistency of high-speed multi-station motor stator winding machines? How to position it more accurately? Vacuz will briefly explain it to you below!

1. Consistency control method

1. High-precision drive system

Direct drive solution: Using a 5000RPM ultra-high-speed servo motor with a zero-backlash torque motor, the transmission error is less than 0.005mm, ensuring the synchronization of each station.

Closed-loop feedback control: real-time monitoring of the spindle position through a nanoscale grating ruler, compressing the error to ±0.008mm, combined with the dynamic PID algorithm to eliminate speed fluctuations, ensuring that the turn error is ≤0.5 turns and the wire diameter deviation is ≤±0.008mm.

2. Tension closed-loop adjustment system

Intelligent tension control: Automatically adjust the tension range according to the wire type (copper wire/aluminum wire). The copper wire tension closed-loop adjustment accuracy reaches ±0.5N, and the aluminum wire automatically reduces the voltage by 15% to avoid uneven tightness of the coil due to tension fluctuations.

Disconnection protection mechanism: In the event of a sudden disconnection, the electromagnetic brake locks the wire reel within 10ms to prevent the equipment from idling or wires from being scattered.

3. Standardized mold and path planning

Parametric mold library: Automatically matches the mold type according to the stator slot distance and stack thickness. The mold change time is ≤30 minutes, reducing manual adjustment errors.

Three-dimensional wiring trajectory algorithm: generates a suitable wiring path, intelligently attenuates 30% speed at corners, and has a wire overlapping rate of <0.1%, ensuring that the coils are tightly arranged and have no intersections.

4.Real-time quality monitoring

Machine vision quality inspection: AI is used to detect the flatness of the wire harness (accuracy 0.02mm), and real-time feedback is provided to adjust the wiring parameters to ensure consistent output at each station.

Self-cleaning die nozzle: Built-in micro air blowing device automatically removes copper chips during the winding process, reducing the scratch rate by 90% and avoiding coil damage caused by impurities.

2. Methods to improve positioning accuracy

1. Fully closed-loop pulse positioning algorithm

High-precision encoder feedback: The motor encoder feeds back the position signal to the PLC in real time. Through high-speed operation of the fully closed-loop function block, the servo motor is controlled to achieve fully closed-loop positioning, with higher positioning accuracy.

Multi-axis collaborative control: Using a bus-type motion controller, it supports multi-axis synchronous motion to ensure accurate connection of winding, wiring, transposition and other actions.

2. High rigidity mechanical structure

Lightweight transmission components: Use carbon fiber cable organizers and magnetic levitation guide rails to reduce mechanical inertia, increase acceleration to 2G, and achieve faster positioning response.

Anti-vibration design: The equipment frame is made of high-strength alloy material and combined with shock-absorbing pads to reduce the vibration amplitude during high-speed operation and avoid positioning deviation.

3. Electronic cam and interpolation technology

Customized electronic cam: The rotating axis, upper and lower axes are bound to the spindle. Through the electronic cam function, high-speed winding and cable arrangement are synchronized, the curve transition is smooth, and the cable arrangement is neat and without intersection.

Spiral rising interpolation foot binding: X/Y/Z three-axis linkage spiral rising interpolation, with high control accuracy, can quickly and accurately fix the enameled wire at the hanging position to avoid positioning deviation.

4. Intelligent debugging and calibration

No-load test and slow-speed debugging: During the installation and debugging stage, perform a no-load test first, gradually increase the speed, and observe whether the running path of the thread nozzle and needle bar is normal and whether the positioning is accurate.

Parameterized storage function: Store debugging parameters for different types of stators and call them directly the next time they are used, reducing repeated calibration time and ensuring positioning consistency.

How to control the consistency of high-speed multi-station motor stator winding machine? How to position more accurately? Vacuz has given a brief explanation above. I hope this knowledge can help everyone!