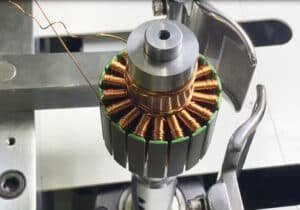

Automatic winding machine is a new type of machine developed in recent years, in order to withstand the high efficiency and high output requirements, fully automatic machines are generally multi-head linkage design, most of the domestic manufacturers are referred to the design of imported models in Taiwan and other places, the use of programmable controllers as the control center of the equipment, with robots, pneumatic control components and executive accessories to complete the automatic line, automatic foot winding, automatic The consumption efficiency of this model is very high, which greatly reduces the reliance on manual labor, and an operator can operate several such devices at the same time, with stable consumption quality, which is very suitable for processing places with high output requirements.

1, mejorar la eficiencia para promover el desarrollo de la industria de la bobina automática fabricantes de la máquina de bobinado automático para cumplir con la producción de la bobina y la automatización de la industria de procesamiento, inteligente, integrado, humano y de ahorro de energía de toda la fila de la tendencia de desarrollo de bobinado, más eficiente y líder en el procesamiento de la bobina de los nuevos métodos de procesamiento inteligente.

2、Operation humanization adopts new control software, operation setting interface is more universal, easier to set, more humanized and can be quickly taught input.

3, the line is tight and beautiful winding machine manufacturers of automatic winding machine using new algorithms to line up closely the whole row, precision row winding is not affected by the wire diameter and BOBBIN error.

4, increase the range of winding machine winding processing many winding machine special fixture can not only clamp a certain, but also can clamp different types of skeleton, and its own device to adjust the position of the fixture itself can also be used in different types of winding machine, these have expanded the range of winding machine winding processing.

5, can ensure relatively stable winding accuracy and product quality in the winding process, the relative position of the skeleton and the row of wire wheel and the edge distance between the capacity is guaranteed, and is not easily affected by other factors, so the product winding accuracy is stable and reliable.

WhatsApp/Wechat: +86 13075286997

Correo electrónico: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]