Stator winding, a crucial motor manufacturing process, requires not only high-quality winding but also precise speed control to meet production capacity demands. So, what are the speed requirements for fully automatic high-speed motor winding machines? How is the speed controlled? Vacuz will provide a brief introduction below!

I. Speed Requirements: Balancing Efficiency, Precision, and Stability

The speed design of fully automatic high-speed motor winding machines must balance production efficiency, winding precision, and equipment stability. Specific requirements are as follows:

1. Speed Range Adaptation

Fine Wire (0.08-0.3mm): Supports high-speed mode (≥3500 rpm), using a dynamic PID algorithm to eliminate the risk of wire breakage and ensure stable wire tension at high speeds.

Coarse Wire (0.8-1.3mm): Automatically switches to a low-speed range (500-1000 rpm) to avoid coil deformation or tension loss due to excessive wire diameter.

1. Large Stator Size (Stack Thickness > 200mm): A frequency reduction strategy (speed reduced by 25%) is implemented, combined with stabilization technology to reduce wire sway and prevent wire routing confusion.

2. Multi-Station Collaborative Speed Increase

Six-station internal winding machines can reach speeds of 1200 RPM, and high-speed external winding machines can reach 5000 RPM, achieving a 5-fold efficiency improvement compared to traditional single-station machines.

Multi-station equipment significantly shortens the individual winding cycle by processing multiple stators in parallel (high-end equipment can reduce it to 5-10 seconds/stator).

3. Acceleration and Deceleration Optimization

High-speed equipment must have rapid start-stop capabilities (such as smooth transition of acceleration change rate) to reduce non-production time (such as mold changes and wire routing adjustments).

Based on a fifth-order polynomial programming S-shaped acceleration and deceleration curve, mechanical shock is reduced by 40%, ensuring stability at high speeds.

4. Synchronization Requirements

Multi-station equipment must ensure synchronized actions at each station to avoid uneven winding or wire breakage due to speed differences.

Synchronization is crucial for ensuring winding quality, especially in multi-wire or complex winding processes.

II. Speed Control Methods: Combination of Precision Systems and Intelligent Algorithms

To achieve high-speed winding while maintaining accuracy and stability, the following technologies are used to control speed:

1. High-Accuracy Drive Architecture

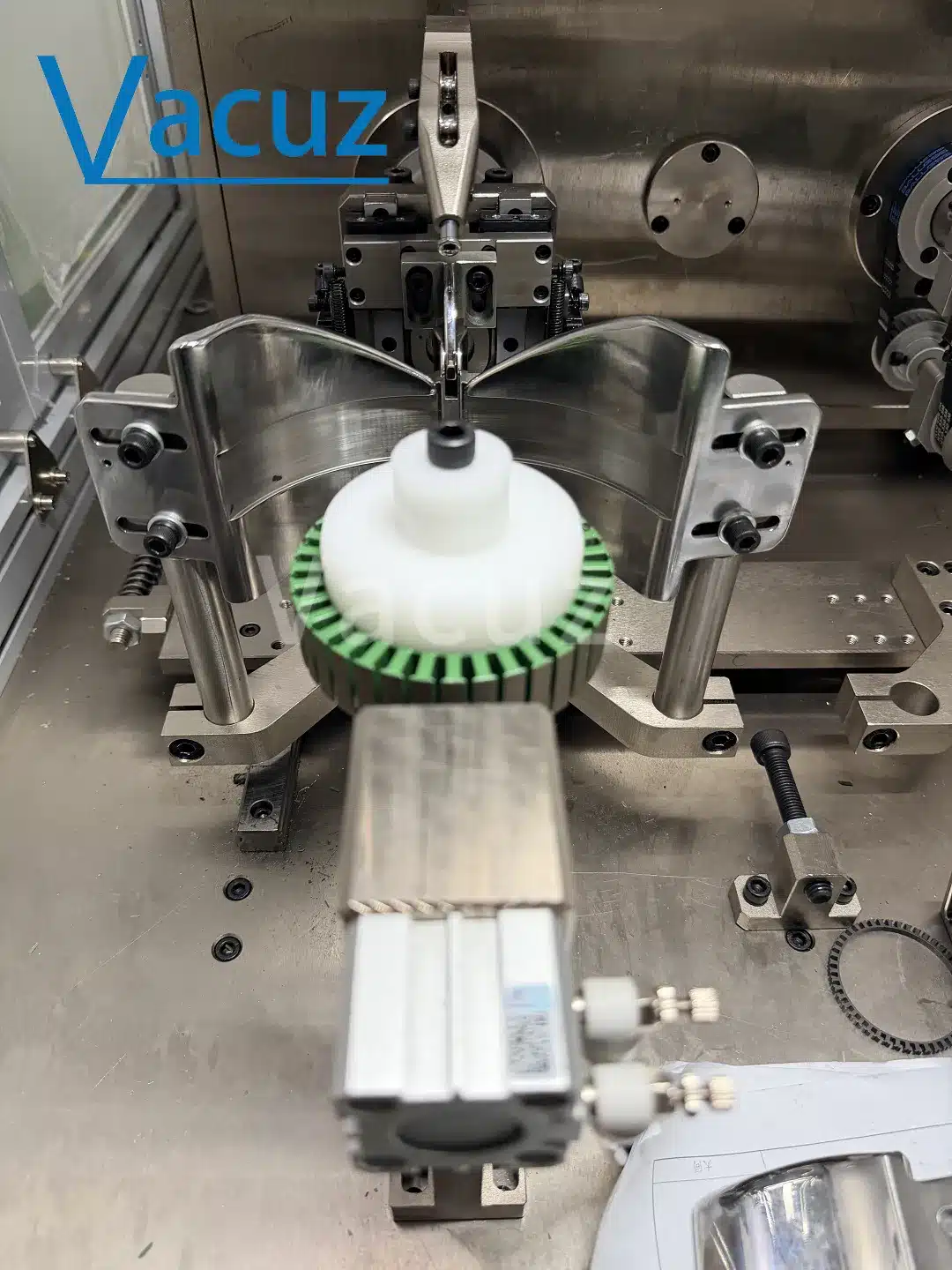

Direct Drive Force Solution: Utilizing a 5000RPM ultra-high-speed servo motor + zero-backlash torque motor, transmission error <0.005mm, and a nanometer-level grating ruler feedback system to achieve winding shape accuracy of ±3μm.

Lightweight Transmission Components: Carbon fiber wire guide combined with a magnetic levitation rail, acceleration increased to 2G, positioning error ±0.008mm.

2. Closed-Loop Tension Control System

Closed-loop tension adjustment for copper wire (5-50N), automatic 15% voltage reduction for aluminum wire, achieving ±0.5N accuracy through real-time feedback from strain gauges.

In the event of a sudden wire breakage, an electromagnetic brake can lock the coil within 10ms to prevent the accident from escalating.

3. Intelligent Wiring and Path Planning

Parameterized Die Library: Automatically matches die type based on slot distance/stack thickness, changeover time ≤ 30 minutes.

Self-Cleaning Die Nozzle: Built-in micro air blowing device automatically removes copper shavings during winding, reducing scratch rate by 90%.

Path Planning Algorithm: Generates 3D wiring trajectory, intelligently reduces speed by 30% at corners, and achieves a overlap rate of <0.1%.

4. Machine Vision Quality Inspection and Feedback

AI detection of wire harness flatness (accuracy 0.02mm), providing real-time feedback to adjust wiring parameters and ensure winding quality.

High-precision visual inspection or laser positioning system monitors wiring accuracy, avoiding issues such as cross-wire and overlap.

5. Segmented Speed Adjustment Strategy

In complex winding processes, segmented speed adjustment is adopted: speed is reduced at the beginning and end of winding, and increased in the middle stage, balancing efficiency and accuracy.

Speed is adjusted in real-time according to changes in wire tension; for example, a pre-tensioning device applies appropriate tension at the wire inlet to reduce fluctuations during high-speed unwinding.

6. Temperature and Vibration Control

Air-cooled or liquid-cooled systems maintain the operating temperature of critical components, preventing thermal deformation caused by high-speed operation.

High-rigidity mechanical structure design (dynamic balance grade G1.0 or higher) withstands centrifugal force and maintains positional repeatability accuracy (±0.01mm level).

III. Practical Recommendations for Speed Optimization

1. Wire Material and Process Compatibility

For thin wires, gradually increase speed to the target value to avoid sudden acceleration leading to wire breakage; for thick wires, control acceleration to prevent coil deformation.

When multiple wires are wound in parallel, equip them with an independent tension control system to address uneven tension at high speeds.

2. Equipment Maintenance and Upgrades

Regularly inspect the wear of mechanical components (such as bearings and gears) and replace them promptly to reduce the risk of high-speed wear.

Upgrade the motors, control systems, or mechanical structures of older equipment to improve speed range and control accuracy.

3. Operator Training

Train operators to master the high-risk operations of high-speed equipment (such as emergency shutdown and troubleshooting) to ensure both safety and efficiency.

4. Data-Driven Optimization

Record speed parameters for different wire materials and processes, and establish a database for quick retrieval and optimization.

Apply Industrial Internet of Things (IIoT) technology to achieve remote equipment monitoring and big data analysis, continuously optimizing production processes.

What are the speed requirements for fully automatic high-speed motor winding machines? How is the speed controlled? Vacuz has provided a simple explanation above; we hope this information is helpful!