As a key equipment in modern motor manufacturing, the fully automatic flying fork stator winding machine has remarkable technical features, ensuring an efficient, accurate and flexible production process. The following is a detailed interpretation of its technical features by Vacuz, hoping to help everyone!

1. High accuracy and high efficiency

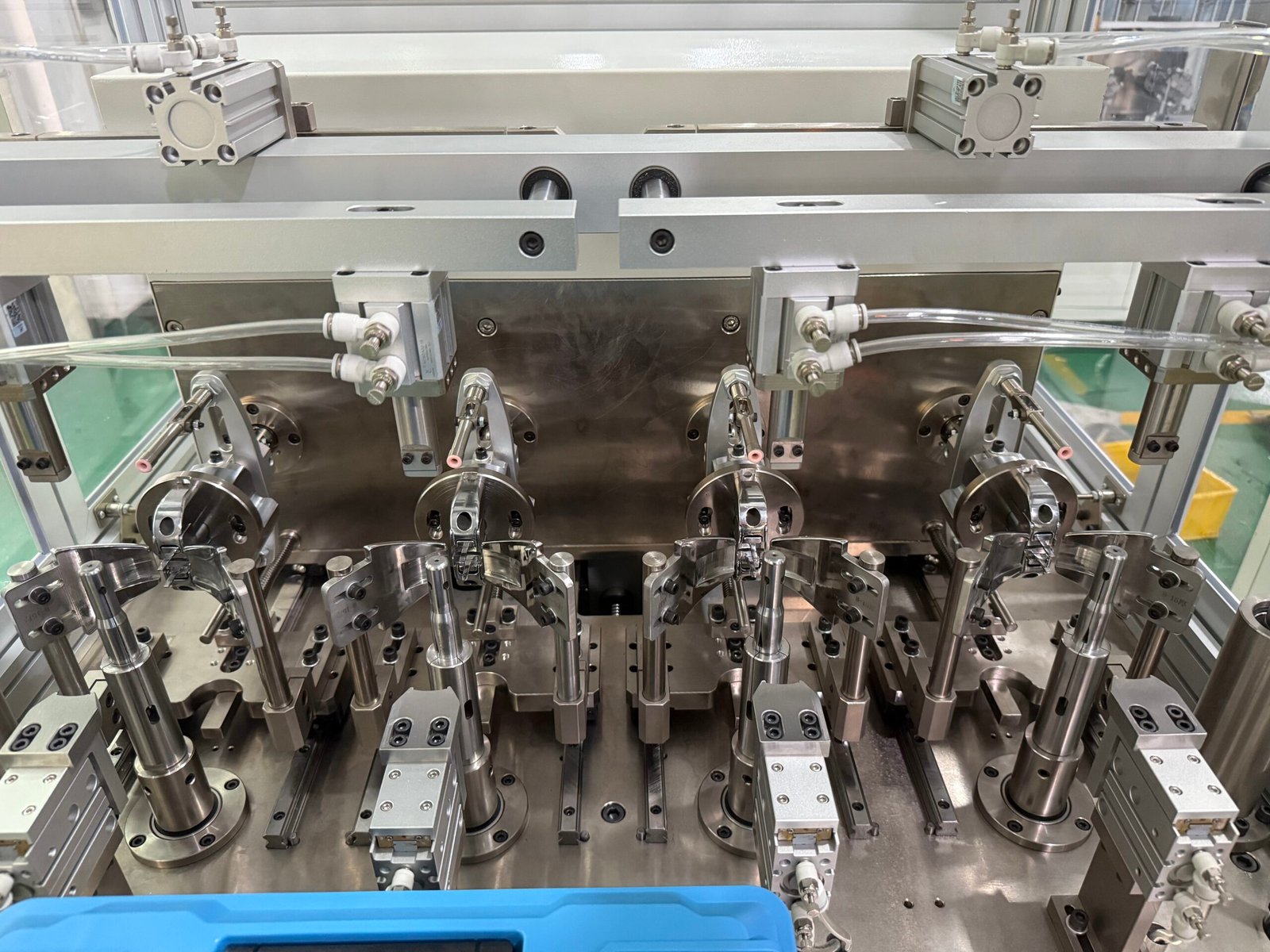

The equipment adopts advanced servo drive and precision control system to accurately perform winding operations. The flying fork structure rotates at high speed to evenly and delicately wind the enameled wire into the stator slot, and cooperates with precise guard plates and die heads to achieve accurate positioning and close arrangement of the coil. In addition, the multi-station design (such as single station, double station, and four stations) is like a multi-line parallel production line, which can process multiple stators at the same time, significantly improving production efficiency and making production smoother.

2. Flexibility and compatibility

The fully automatic flying fork stator winding machine demonstrates its strong adaptability and inclusiveness. It supports single-strand or multi-strand winding, with a wide range of wire diameters, from 0.1mm to 1.3mm (special needs can also be customized), meeting the needs of wires of different specifications. By simply replacing the mold, the equipment can quickly adapt to stators of different sizes and shapes. Whether it is a model aircraft motor, a new energy vehicle motor or a cooling fan motor, it can easily cope with it, showing its wide application prospects.

3. Automation and intelligence

The equipment integrates the essence of automation and intelligence, and realizes the automation of the entire process from automatic loading and unloading, automatic clamping, winding to wire cutting. Operators only need to easily take and put materials to complete production, which greatly reduces labor intensity. At the same time, the human-machine interface is like the intelligent brain of the equipment, allowing users to freely set parameters such as winding speed, tension, and cross-slot, and monitor the equipment status in real time to ensure the stability and traceability of the production process, making production more intelligent and transparent.

3. Modularity and maintainability

The equipment adopts a modular design, which is flexible like building blocks, and key components (such as fixtures and molds) are easy to replace and maintain. This design not only reduces maintenance costs, but also improves the reliability and service life of the equipment. Regularly checking the accuracy and smoothness of the mold and stator frame is like doing a fine maintenance for the equipment, which can avoid wire damage and ensure production quality.

4. Precautions during the outer winding process

During the outer winding process, wire diameter and tension control, equipment adaptability, operating specifications, and equipment maintenance and care are all crucial. When winding thick wires, the speed needs to be reduced and the tension needs to be reduced; when winding thin wires, the tension needs to be stable. At the same time, for special wire diameters or stator shapes, special machines need to be selected or customized. In terms of operating specifications, it is necessary to flexibly adjust the winding speed, design a reasonable winding path, and use auxiliary tools to reduce the tension and bending force of the wire. Equipment maintenance and care should not be ignored. Regular inspection of key components and monitoring of equipment operating status are the key to ensuring long-term and stable operation of the equipment.

5. Safe operation

Safety is always the first priority. Operators need to wear protective equipment to avoid scratches on the wire or injuries from splashes. At the same time, the equipment should be equipped with an emergency stop button to ensure that it can stop running quickly under abnormal circumstances to ensure the safety of personnel and equipment.

In summary, the fully automatic flying fork stator winding machine has shown strong competitiveness in the field of motor manufacturing with its high accuracy, high efficiency, flexibility, compatibility, automation and intelligence, modularity and maintainability. At the same time, we should also pay attention to the precautions and safe operating specifications during the external winding process to ensure the smooth progress of production.

Correo electrónico: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]