In the process of motor manufacturing, it is crucial to ensure the accuracy and stability of the rotor automatic assembly production line. Vacuz analyzes the key technical strategies to improve the accuracy and stability of the rotor automatic assembly production line, hoping to help everyone!

Kiire automaatne harjatud armatuuri rootori staatori mootori mähise pilu soonitud kiilu isolatsiooni paber sisestamise montaažimasinaga

1. Equipment performance and reliability optimization

1. High-precision automated assembly equipment:

Select high-precision and highly automated assembly equipment, such as advanced robotic assembly systems, to minimize human errors.

Ensure that the assembly equipment has excellent stability and reliability, reduce downtime, and ensure the continuous and efficient operation of the production line.

2. Modular and scalable design:

Adopt modular design concepts to improve the flexibility and maintainability of equipment.

Each module operates independently, which is convenient for performance optimization and technology upgrades for specific needs, ensuring the long-term stable operation of the production line.

3. Intelligent monitoring and control system:

Introduce advanced control systems to realize automatic monitoring and fault diagnosis of equipment.

Use production data analysis functions to provide strong support for continuous improvement and performance improvement of equipment.

2. Process optimization and standardization implementation

1. Process streamlining and efficiency improvement:

Through process reengineering, redundant links are removed, operation steps are simplified, and assembly efficiency is improved.

Ensure seamless connection between each workstation, adopt parallel operation mode, and further improve production efficiency.

2. Standardized operation process and specifications:

Formulate strict standardized operation process and operation specifications to reduce the risk of human operation errors.

Ensure the consistency and stability of the assembly process, thereby improving product quality and customer satisfaction.

3. High-precision tooling and positioning technology:

Design and select high-precision tooling and positioning devices to ensure the stability and accuracy of the rotor during the assembly process.

Strictly screen and test the tooling material, structure and processing accuracy to meet production needs.

3. Real-time monitoring and data analysis application

1. Sensor and monitoring technology:

Widely apply sensor technology to monitor subtle changes in the assembly process in real time.

Timely discover and deal with potential problems to ensure the stability and accuracy of the assembly process.

2. Data analysis and continuous improvement:

Use data analysis tools to deeply explore the key factors affecting production efficiency.

Formulate targeted improvement measures, continuously optimize assembly processes, and improve production efficiency and product quality.

IV. Strengthening material management and quality control

1. Improve the material management system:

Establish a complete material management system to ensure the timeliness and accuracy of material supply.

Use advanced inventory management systems and material tracking technologies to reduce the risk of production delays.

2. Strict quality control:

Strict quality inspection and control of raw materials and parts.

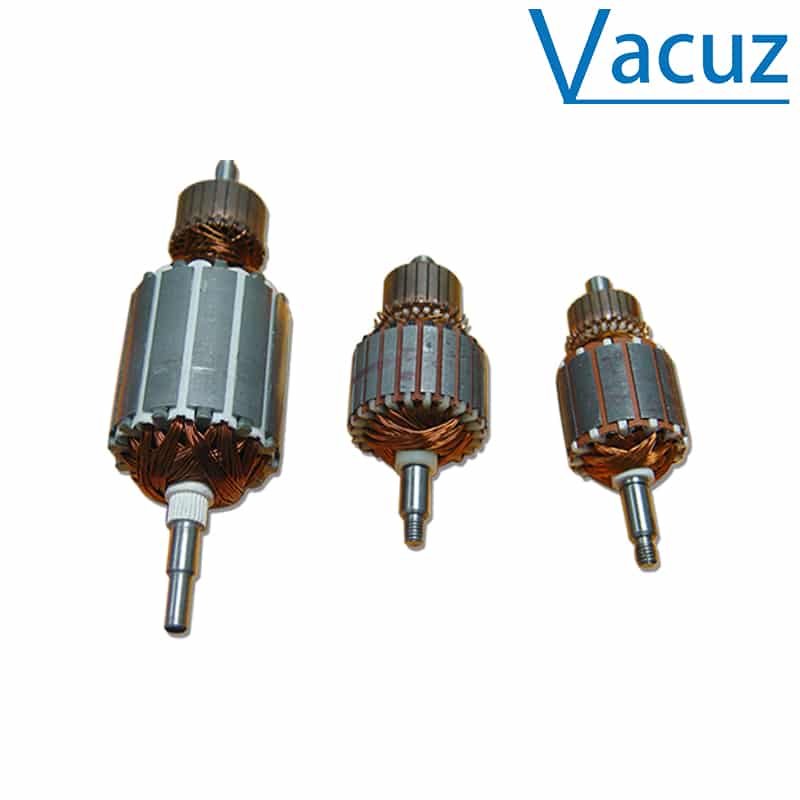

Ensure that the quality of the rotor before assembly meets the design requirements and provides strong guarantees for the stable operation of the production line.

V. Personnel training and incentive mechanism construction

1. Skill improvement and training:

Regularly conduct skill training for employees to improve their assembly operation level and skill proficiency.

Ensure that employees can operate assembly equipment proficiently, reduce human errors, and improve production efficiency.

2. Incentive mechanism and innovation atmosphere:

Establish an effective incentive mechanism to encourage employees to actively participate in the improvement and innovation activities of the production line.

Stimulate employees’ enthusiasm for innovation, contribute to the continuous optimization of the production line, and improve overall production efficiency.

VI. Strengthening equipment maintenance and care

1. Regular maintenance and care:

Maintain and care the equipment regularly to ensure that the equipment is in good working condition.

Perform regular inspection and replacement of key components to prevent potential failures and extend the service life of the equipment.

2. Equipment maintenance file management:

Establish a complete equipment maintenance file and repair record to facilitate timely tracking and solving equipment problems.

Provide strong support for the continuous improvement and optimization of equipment.

VII. Environmental control and adaptability improvement

1. Environmental optimization and control:

Strictly control environmental factors such as ambient temperature, humidity and cleanliness of the production line.

Reduce the impact of the external environment on production stability and ensure good ventilation and lighting conditions at the production site.

2. Flexibility and adaptability:

Design adjustable tooling and positioning devices to meet the needs of rotors of different sizes and shapes.

Provide customized assembly solutions to meet the diverse needs of customers and enhance market competitiveness.

BLDC mootori staatori mähise tootmisliin

In summary, the accuracy and stability of the rotor automatic assembly production line can be significantly improved through efforts such as optimizing equipment performance, standardizing process flow, strengthening real-time monitoring and data analysis, improving material management and quality control, building personnel training and incentive mechanisms, strengthening equipment maintenance and care, and improving environmental control and adaptability. These technical strategies are crucial to ensuring high quality and high efficiency in the motor manufacturing process.

E-post: sales@vacuz.com