Accompanied by the vigorous development of high-tech, contemporary automatic coil winding machine because of the collection of electrical control, mechanical transmission, photoelectric detection and many other technologies, so it is set to debug the difficulty coefficient has also greatly increased. Many customers in the purchase of the winding machine, for its settings often can not find the direction of this article on the automatic armature rotor winding machine functions and common debugging methods listed below:

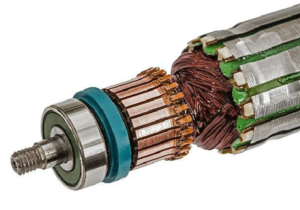

Armature Rotor

First, familiar with the function of the equipment and winding process

When you buy the armature rotor winding machine after the first to power on the no-load test run, this process is the key to test the operation of the winding machine is not smooth, is not anomalous noise, as a debugger in this process should be referred to the winding machine instruction manual to check one by one each function is effective, but also to familiarize themselves with the process of the equipment, begin to familiarize themselves with the equipment function after the product to be combined with their own After starting to familiarize with the functions of the equipment, we should find the corresponding functions of the equipment in combination with our own products, and check whether the functions of the equipment are in line with the requirements of the winding process, and the functional requirements of the equipment need to be meticulously communicated with the equipment suppliers during the procurement process, so as to prevent the purchase of equipment and the requirements of the winding line from not being in line with the equipment should be noted that the permissible diameter of the line of the equipment, the maximum load, the width of the line and its accuracy, which are the basic data to measure the requirements of the equipment and the winding line. These parameters are the basic data to measure whether the equipment meets the winding requirements or not.

Second, the setting of equipment accessories and data measurement

Commissioning personnel familiar with the functions and parameters of the equipment, but also on the automatic armature rotor winding machine tension adjustment and winding mold information for the determination of the normal winding of the wire diameter used in the larger the tension should be greater, not the same manufacturers of the equipment tension adjustment range are slightly different, the use of aluminum and copper wire required tension is not the same, the same diameter of aluminum wire required tension than the copper wire smaller, tension adjustment range is slightly different, the same diameter of aluminum wire than the copper wire, tension adjustment range is slightly different, the same diameter of aluminum wire than the copper wire. Aluminum wire of the same wire diameter requires a smaller tension than copper wire, the tension adjustment will cause the actual winding on the mold wire diameter becomes smaller, if it is a fine line, there will be pulled off, knotting phenomenon, the tension is too small will be swollen coils, rows of messy phenomena, so the tension adjustment is a very important setup, the different diameters of the wire will have a safe range of tension, the “Enameled Wire Safe Tension” book has a detailed description of debugging personnel should be carefully referred to the winding molds. Determination, should pay attention to the width and height of the mold, and the winding rod is not a match, too tight will affect the mold loading and unloading, too loose will also lead to mold shaking affect the effect of the line.

Ankkuri Rotor BLDC Harjaton Drone Motor Ulkoinen staattori Automaattinen Flying Fork Coil Winding Machine

WhatsApp/Wechat: +86 13075286997

Sähköposti: sales@vacuz.com