When winding the stator of a motor, you must first evaluate the parameters and determine what winding machine to use. If you do not choose the right one, the winding quality and efficiency will be affected. So how to evaluate the difficulty of winding the stator of a brushless motor? How to select suitable winding machine equipment? Vacuz will analyze it for you below!

Inner BLDC Motor Stator Coil

There are many aspects to the difficulty of evaluating the stator windings of brushless motors. Here are some key considerations:

1. Stator and related parameters: stator outer diameter, inner diameter, lamination thickness (height), etc. All affect the difficulty of winding.

2. The quality and wire diameter of enameled wire: The quality and wire diameter of enameled wire are crucial to the winding process.

3. Winding speed: The winding speed needs to be set according to the outer diameter of the stator and the diameter of the enameled wire. Too fast a speed may cause damage or breakage of the enameled wire.

4. Parallel winding of multi-strand wires and number of coil turns: Parallel winding of multi-strand wires is a common winding method, which has advantages over winding a single thick wire.

5. Mold accuracy and positioning: Mold accuracy and positioning are equally important to the winding process. The mold needs to be carefully manufactured and accurately positioned to ensure the smooth progress of the winding process.

When selecting suitable winding machine equipment, the following factors should be considered:

1. Equipment performance: The equipment should have sufficient speed to meet production needs, ensure product quality, and good stability and reliability to ensure production efficiency and stability.

2. Equipment quality: Choose equipment with good quality and guaranteed brand, and avoid choosing equipment with low price and poor quality. Information such as the manufacturer, brand, and market reputation of the equipment is also an important reference.

3. Equipment functions: According to the actual needs of the enterprise and the characteristics of the product, select equipment with complete functions that meet the needs. Different winding machine equipment has different functions, including degree of automation, winding method, control system, etc.

4. Equipment price: The price of equipment is one of the factors that need to be considered when choosing. Factors such as the performance and quality of the equipment should be comprehensively considered to select equipment with an appropriate price and high cost performance.

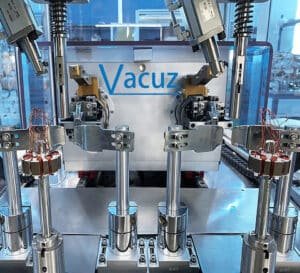

Two Stations Hub Motor Electric Vehicle E Bike Automatic BLDC Brushless Drone Outer Stator Coil Flying Fork Winding Machine Manufacturer Cost

How to evaluate the difficulty of winding the stator of a brushless motor? How to select suitable winding machine equipment? Vacuz has given a brief introduction above. I hope these little knowledge and details can help everyone!

Sähköposti: sales@vacuz.com