The working efficiency of the brushless motor stator winding machine, especially the speed of winding, is not determined by a single factor, but the result of the combined effect of multiple factors. The following is an in-depth analysis of these key factors by Vacuz, hoping to help everyone!

Vertical Lab Type Automatic Electrostatic Epoxy Powder Coating Machine For Rotor Drone Stator BLDC FPV UAV Motor Core

1. Mechanical structure and configuration

1. Infrastructure: The structural elements such as the chassis, workbench and frame of the winding machine are crucial to its stability during operation. Usually a sheet metal base, aluminum alloy frame and stainless steel workbench are used. This combination ensures that the machine is still stable and reliable at high speeds.

2. Motion components: The performance of moving parts such as motors, cylinders, and screws directly affects the speed and accuracy of winding. Especially when performing high-speed internal winding or precision wiring, the selection of high-quality imported servo motors and high-quality cylinder screws is the key to ensuring winding speed and accuracy.

3. Control system: The accurate control of the servo drive system is inseparable from the cooperation of high-quality controllers and servo motors. Only with such a combination can accurate control during the winding process be achieved.

4. Wire arrangement and mold: The close cooperation between the wire arrangement device and the mold is the basis for ensuring the high-speed and stable operation of the equipment. The processing accuracy of the mold and the accuracy of installation and debugging are directly related to the effect of winding.

2. Stator characteristics

1. Dimension parameters: The dimensional parameters such as the outer diameter, inner diameter and stack thickness (height) of the stator directly determine the model of the required winding equipment. Different size ranges may require different equipment to adapt.

2. Wire diameter influence: The thickness of the wire diameter directly affects the winding speed. For micro brushless motors, the wire diameter is generally between 0.08mm and 1.3mm. The thinner the wire diameter, the faster the winding speed can be set, and when the wire diameter is thicker, the winding speed needs to be reduced accordingly.

3. Multi-wire winding and notch: When multiple strands of copper wire are wound in parallel, the speed will decrease as the number of copper wires increases. In addition, the smaller the notch distance, the winding speed also needs to be adjusted accordingly to avoid scratching or breaking the enameled wire.

4. Shape and direction: The shape and slot direction of the stator will also affect the operating efficiency of the winding machine. For example, a skewed slot stator may require a special winding method.

III. Auxiliary equipment

1. Tension control: The selection and control of the tensioner is crucial to the winding quality. Especially when winding at high speed, the use of a professional servo active wire feeding tensioner can ensure the appropriate tension, thereby maintaining the stability of the winding speed.

2. Other accessories: The reasonable selection and use of accessories such as wool felt and wire nozzles can also ensure the tension of the enameled wire and avoid wire breakage or wire damage during high-speed winding.

IV. Other considerations

1. Wire quality: The wire diameter and material of the enameled wire have a direct impact on its performance at high speed. The selection of suitable wire can ensure that it can withstand tension at high speed without breaking easily.

2. Precision wire arrangement requirements: For customers who need to achieve precision wire arrangement effects, the speed needs to be appropriately reduced to ensure the quality of wire arrangement.

3. Debugging technology: Professional debugging and after-sales service are also the key to ensure stable operation of the machine and meet customer needs. Through professional debugging, the machine can be adjusted to the best state, thus achieving high-speed and stable production.

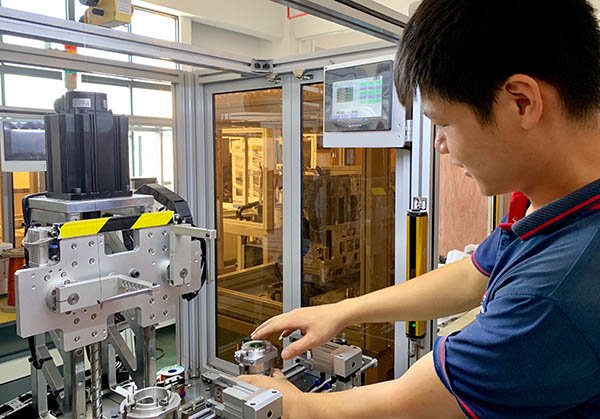

Stator Winding Machine Adjustment

In summary, the winding speed of the brushless motor stator winding machine is closely related to many factors. When purchasing and using the winding machine, these factors must be considered comprehensively to ensure that the appropriate equipment is selected and its performance is brought into play.

Sähköposti: sales@vacuz.com