In the process of motor manufacturing, the rotor as a core component, the stability of its operation directly affects the performance and life of the whole machine. However, the phenomenon of unstable operation of rotor production line occurs from time to time, and the reasons behind it are complex and diverse. Vacuz will analyze the reasons for unstable operation of rotor production line from various aspects and put forward corresponding stabilization measures, hoping to help you!

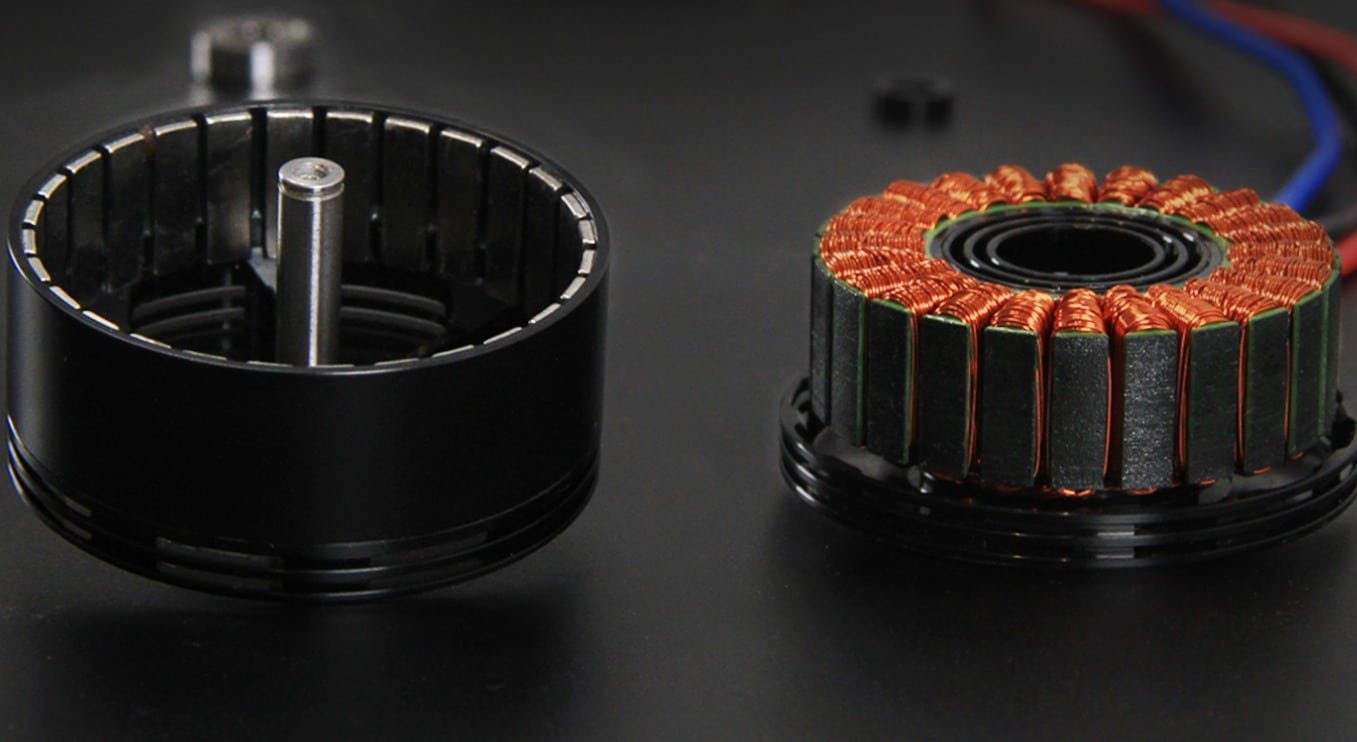

High Power Electric Bldc 2807 Stator And Rotor Compact Fpv Drone Motor 24v 1300kv Brushless Small Rc Motor For Model Aircraft

First, the reasons for unstable rotor production line operation

1. Uneven distribution of rotor quality, uneven density of raw materials, uneven weld structure of the weld, the existence of porosity in the casting and other issues will lead to the rotor in the rotation process to produce instability.

2. Design and processing defects

a. Some special structures are difficult to use symmetrical design, such as crankshaft structure, etc., the asymmetry of the design will increase the risk of imbalance.

b. Low level of processing technology, defective parts structure or installation errors, is also an important cause of rotor imbalance.

3. Wear and deformation during operation

a. Long-term operation of the rotating system, parts wear is difficult to avoid, wear and tear may trigger the rotor system imbalance.

b. The rotating body may be deformed by thermal expansion, which further affects the stable operation of the rotor.

4. Environmental factors

a. Changes in temperature and humidity may cause volume changes in the rotor material, resulting in uneven mass distribution.

b. External vibration, shock and other disturbances will also have an impact on the stable operation of the rotor.

5. Problems during assembly

a.Poor fit between parts or inaccurate mounting position can lead to changes in rotor mass distribution.

b. Negligence or incorrect operation in the assembly process may also lead to rotor imbalance.

Second, to ensure the stability and reliability of the rotor assembly measures

1. Optimize the design

a. Adopt symmetrical structure design to minimize the unbalance caused by design reasons.

b. According to the actual demand, reasonably determine the size, material and structure of the rotor to ensure that it has good mechanical properties and stability.

2. Improve the manufacturing and processing precision

a. Strictly control the quality of raw materials to ensure uniform distribution of materials.

b. Improve the level of processing technology to reduce processing errors and defects.

c. Conduct fine processing and testing of key parts to ensure that they meet the design requirements.

3. Strict assembly process

a. Formulate detailed assembly process specifications and operation procedures to ensure the accuracy and reliability of the assembly process.

b.Adopt highly accurate and stable assembly equipment to improve assembly precision.

c. Strengthen the monitoring and testing of the assembly process to find and correct problems in time.

4. Regular maintenance and inspection

a. Carry out regular maintenance and inspection of the rotor, timely detection and treatment of wear, deformation and other problems.

b.Regularly replace or repair the key components to ensure that they are in good condition.

5. Control the operating environment

a. Keep the temperature and humidity of the production environment stable, reduce the impact of environmental factors on the stability of the rotor.

b.Carry out effective isolation and damping treatment for external vibration, shock and other disturbances.

6. Strengthen personnel training and management

a. Provide professional training for operators to improve their operating skills and quality awareness.

b. Formulate perfect quality management system and operation specification to ensure that all the work is carried out in an orderly manner.

7. Introduce advanced technology and equipment

a. Introduce highly accurate and automated production equipment and testing instruments to improve production efficiency and product quality.

b.Adopt advanced monitoring and diagnostic technology to monitor and evaluate the rotor operation status in real time.

High Power Electric Bldc 2807 Stator And Rotor Compact Fpv Drone Motor 24v 1300kv Brushless Small Rc Motor For Model Aircraft

To sum up, through the optimization of design, improve manufacturing and processing precision, strict assembly process, regular maintenance and inspection, control of the operating environment, strengthen personnel training and management, and the introduction of advanced technology and equipment, etc., can effectively ensure the stable operation of the rotor production line and the stability and reliability of rotor assembly. This is of great significance to improve the production efficiency and product quality of motor manufacturing enterprises.

Sähköposti: sales@vacuz.com