Fully automatic internal winding machines employ a needle-type upper and lower winding structure, primarily designed for stators with inward-facing slots. Their configuration and requirements are relatively high. So, what are the requirements for the model and configuration of a fully automatic internal winding machine? How can you distinguish a good machine from a bad one? Below, Vacuz will give you a brief introduction!

I. Model Selection Basis

Applicable Motor Type and Number of Poles:

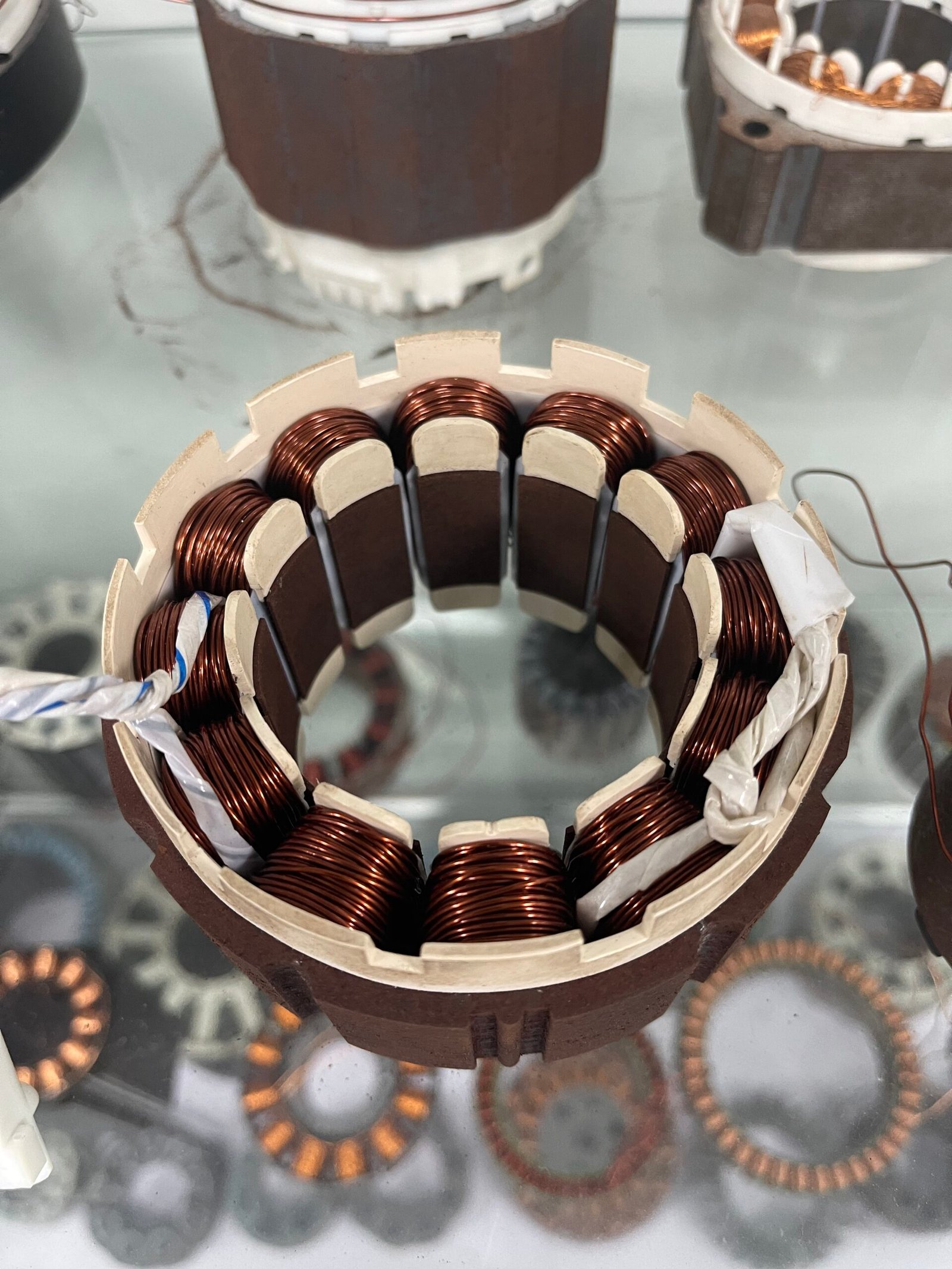

Designed specifically for 6-12 pole motors, supporting 2-pole and 4-pole internal winding of stators. It can wind two stators simultaneously, meeting the production needs of multi-pole motors.

Suitable for 2, 4, 6, and 8-pole motors, with stator outer diameters ranging from Φ70mm to Φ132mm and stack thicknesses from 10mm to 60mm, covering small and medium-sized motor specifications.

II. Core Configuration Requirements

1. Power System

Servo Motor: Employs a high-precision servo motor to ensure speed stability and torque output.

Transmission Components: Uses high-precision ball screws and imported bearings to reduce mechanical wear and improve motion accuracy.

2. Control System

Intelligent Control Unit: Equipped with a PLC or touchscreen human-machine interface, supporting one-click parameter setting and self-diagnosis of faults.

Multi-axis Cooperative Control: High-end models adopt a 6-axis control system, realizing multi-axis linkage of the main spindle, drawing spindle, and winding width axis, improving winding complexity.

3. Winding Mechanism

Wire Laying Device: Must have automatic cornering and automatic wire feeding functions to ensure tight and flat coil arrangement.

Tension Control: Equipped with a high-precision tensioner to prevent wire stretching or breakage.

4. Structure and Materials

Frame Design: Uses high-strength aluminum alloy profiles or thickened sheet metal to ensure equipment stability.

Protective Devices: Equipped with protective covers, LED lighting strips, and other detailed designs to improve operational safety.

Fully Automatic Internal Winding Machine Quality Identification Methods:

I. Appearance and Configuration Inspection

Equipment Integrity: Observe the appearance for bumps or damage, and check whether key components such as servo motors, lead screws, guide rails, and cylinders are complete and meet specifications.

Material and Workmanship: Touch the frame surface to check the sheet metal thickness (e.g., ≥3mm) and the material of the connecting plates (e.g., 45# steel). High-quality models show no surface peeling or deformation.

II. Installation, Debugging, and Testing

No-load Operation: After starting the equipment, observe its operational stability and check if the speed meets the standard (e.g., rated speed 0-1000rpm). Check if the bearings and moving parts are overheating or emitting abnormal noise.

Load Test: Use standard wire to perform a winding test, checking the accuracy of the winding count, the flatness of the wiring, and the integrity of the enameled wire insulation.

III. Performance Indicator Evaluation

1. Accuracy and Efficiency:

Winding Accuracy: Measure the coil turn error (e.g., within ±1 turn) and wiring accuracy (e.g., end neatness ≤0.5mm).

Production Efficiency: Record the output per unit time (e.g., 150 pieces/hour) and evaluate the changeover time (e.g., changing one mold every ≤30 minutes).

2. Intelligence and Reliability:

Intelligent Functions: Check whether it is equipped with a self-diagnostic system (e.g., fault code display) and programmable parameter functions (e.g., turn count, direction setting). Mechanical Stability: After 8 hours of continuous operation, check for wear on mechanical parts and for electrical system malfunctions.

IV. Noise and Versatility

Noise Level: The noise level during equipment operation should be ≤70dB. Low-noise models are typically more compact (e.g., using a soundproof enclosure).

Versatility: Confirm whether the equipment supports non-standard customization (e.g., extended wire diameter range, special coil shape winding).

V. After-Sales Service and Support

Warranty Policy: Prioritize manufacturers offering at least a 1-year warranty on the entire machine and 24-hour repair response.

Technical Support: Confirm whether the manufacturer provides operation training and remote troubleshooting services (e.g., video guidance).

What are the requirements for the model and configuration of a fully automatic internal winding machine? How to distinguish between good and bad machines? Vacuz has provided a simple explanation above; we hope this information is helpful!