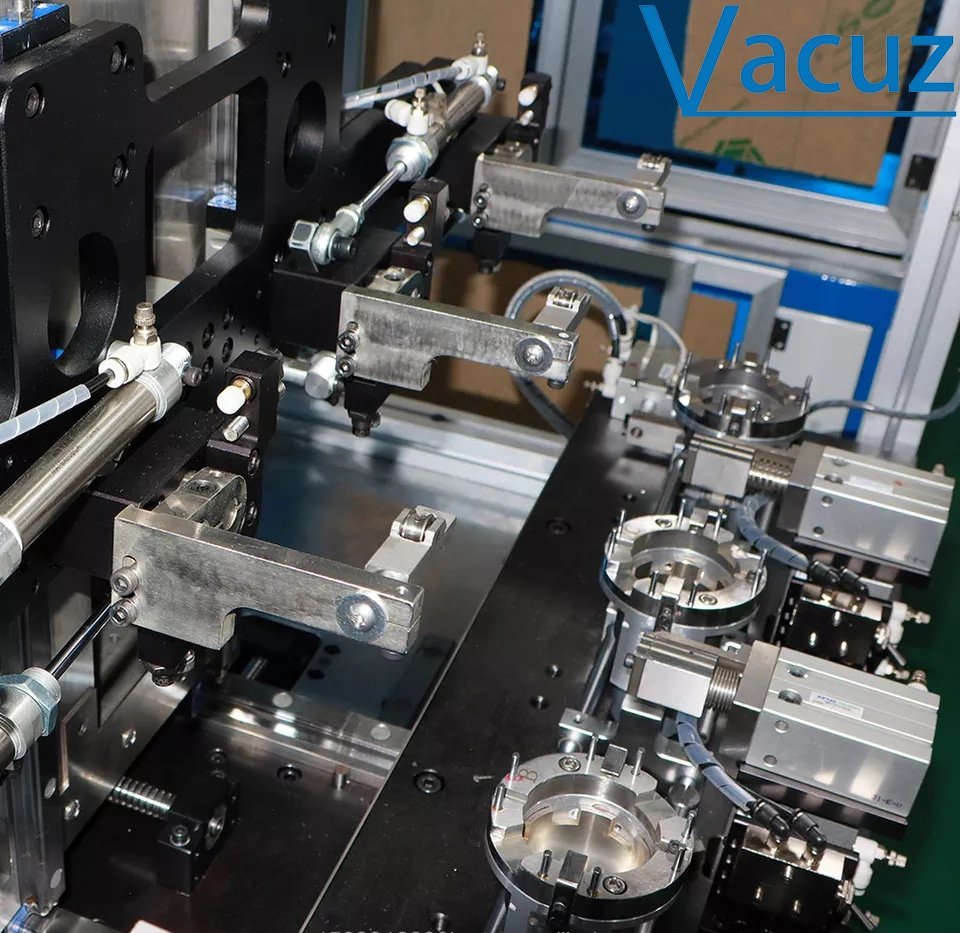

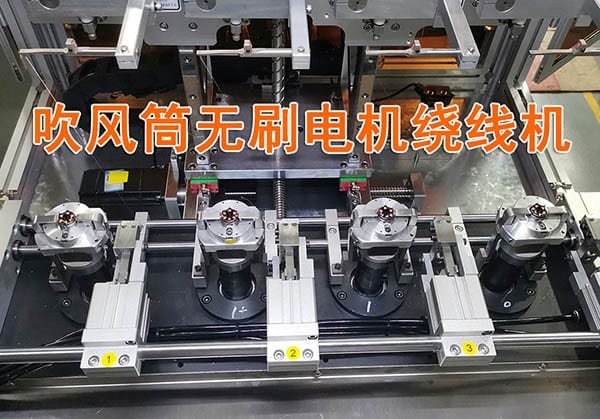

High-speed motor stator winding machine running speed is very fast, some reach more than 1000RPM, if the machine configuration is not good or quality is not pass, or some reasons for debugging, a little improper, it is easy to lead to the problem of wounding and breaking the line, so what is the reason for the high-speed motor stator winding machine wounding and breaking the line? How to quickly adjust the program, Vacuz give you an introduction to it!

High-speed motor stator winding machine wire breakage causes analysis:

1. Excessive speed: silk rod or belt drive speed exceeds the upper limit, easy to lead to wire breakage.

2. Improper tensioner settings: too much tension to pull the broken wire, too small is loose or knotted wire.

3. Enameled wire problem: wire diameter, material does not match, need to adjust the parameters.

4. Insufficient precision of stator skeleton and mold: machining is not precise, there are burrs easy to scrape the line.

5. Problems with auxiliary components: wire wheel, wool felt and other foreign objects or broken card line.

6. Equipment configuration and quality: servo motors, drive controllers of poor quality, inaccurate control.

High-speed motor stator winding machine injury line broken line quick adjustment program:

1. Adjust the speed: adjust according to the instructions, do not exceed the upper limit, you can try to gradually reduce the speed.

2. Adjust the tensioner: make sure the tension is in a reasonable range, check the inductor is not faulty.

3. Check and replace the enameled wire: make sure the wire diameter and material meet the requirements of the equipment.

4. Improve the production precision: regularly check and maintain the stator skeleton and mold, remove burrs.

5. Check and replace auxiliary parts: Make sure there are no foreign objects and breakage, and replace them in time.

6. Upgrade or replace equipment: Consider equipment configuration and quality issues, choose reliable equipment.

What is the reason for wounding and breaking wire of high-speed motor stator winding machine? How to quickly adjust the program? Vacuz above has made a simple explanation, through the above adjustment and maintenance measures, you can reduce wire breakage, improve production efficiency and product quality.

Email : sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]