With the rapid development of the motor industry, the use of small and medium-sized motors is becoming more and more widespread, such as brushless motors, often used in household appliances, medical equipment, pumps, fans, new energy vehicles, electric tools and other industries, because the supply is too large, so it can not be solved by artificial, with the development of intelligent manufacturing technology, in order to solve the problem of insufficient labor and diversity of demand, intelligent automated production has become a good choice.

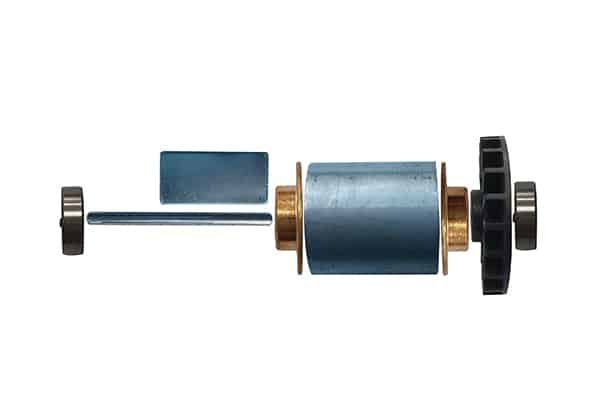

The motor is mainly used to realize the conversion between electrical energy and mechanical energy, mechanical energy and electrical energy. The motor rotor is the rotating part of the motor, and together with the stator, it is the more core part of the motor, so how about the motor rotor automation production line solution?

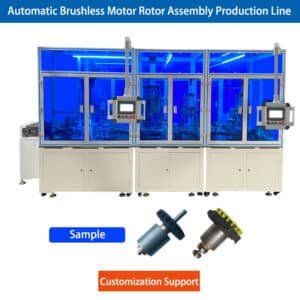

The motor rotor automation production line uses robots to connect the front-end production modules of the rotor, including the material tray, commutator rough machining, commutator slotting, commutator brush burr, fan shaft entrance, balancer and comprehensive inspection. It is suitable for BLDC motor rotor assembly, including shaft insertion, magnetic insertion, magnetizing, balancing and other processes.

1. Rotor automation production line can greatly save operators, reduce labor cost, improve production environment and optimize management.

2. It can run 24 hours a day, and can organize production with high intensity and efficiency without being affected by personnel factors, and improve equipment utilization.

3. Industrial robots eliminate the safety hazards of manual operation and can avoid unnecessary safety production accidents.

4. Strict standardized operation, high process stability, stable production capacity, enhance the image of enterprise technology and strength, and more competitive in the market.

5. Programmable processing data, flexible machine, easy to set and operate.

6. Each machine works independently and automatically, the operator needs to manually load and unload.

These are the solutions for the automated production line for motor rotors. I am sure you have read them all. Vacuz can complete tailor-made innovative solutions for motors to meet all quality and production requirements, whether it is rotor, stator or complete assembly work for the whole motor production.

WhatsApp/Wechat : +86 13075286997

Email : sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]