With the rise of the motor industry, all walks of life use motor, motor demand increases, the production also have to improve the speed, so began the intelligent production, such as motor stator and rotor production line, instead of manual labor, improve the production efficiency, then the motor rotor production line and stator production details and requirements are? Take a look!

Motor stator production line mainly includes key processes such as coil forming, wire insertion, head twisting and welding, in which the average production beats of coil forming machine, automatic wire insertion machine, head twisting machine and welding machine are 4/360/50/3s respectively, realizing the highly automated operation of stator production line.

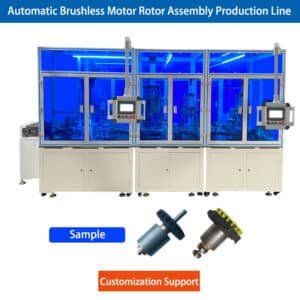

The motor rotor production line mainly includes key processes such as core insertion of magnets, core injection molding, rotor stacking and rotor magnetization, in which the stable performance of equipment operation, smoothness of articulation of various components, equipment flexibility and real-time monitoring functions are all important requirements.

During the production process, the quality of each step of the process needs to be ensured, and if any problem is found, it needs to be re-commissioned until it meets the requirements.

Overall, the motor rotor production line and stator production line have their own key processes and requirements, which need to be adjusted and optimized according to the specific production environment and needs.

WhatsApp/Wechat : +86 13075286997

Email : sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]